- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V±5% ,50Hz

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

15000

-

Technology:

-

vacuum Coating

-

Coating film:

-

metal film

-

Pressure raising rate:

-

<0.67Pa/h

-

Cycle cooling water:

-

300L/H

-

Environmental temperature:

-

about 25℃

-

Relative humidity:

-

<80%

-

Compressed air:

-

0.5~0.7Mpa

-

Limit vacuum degree:

-

8*10-4Pa

-

Application:

-

Package,Printing,Textile,Electronic industry

Quick Details

-

Machine Type:

-

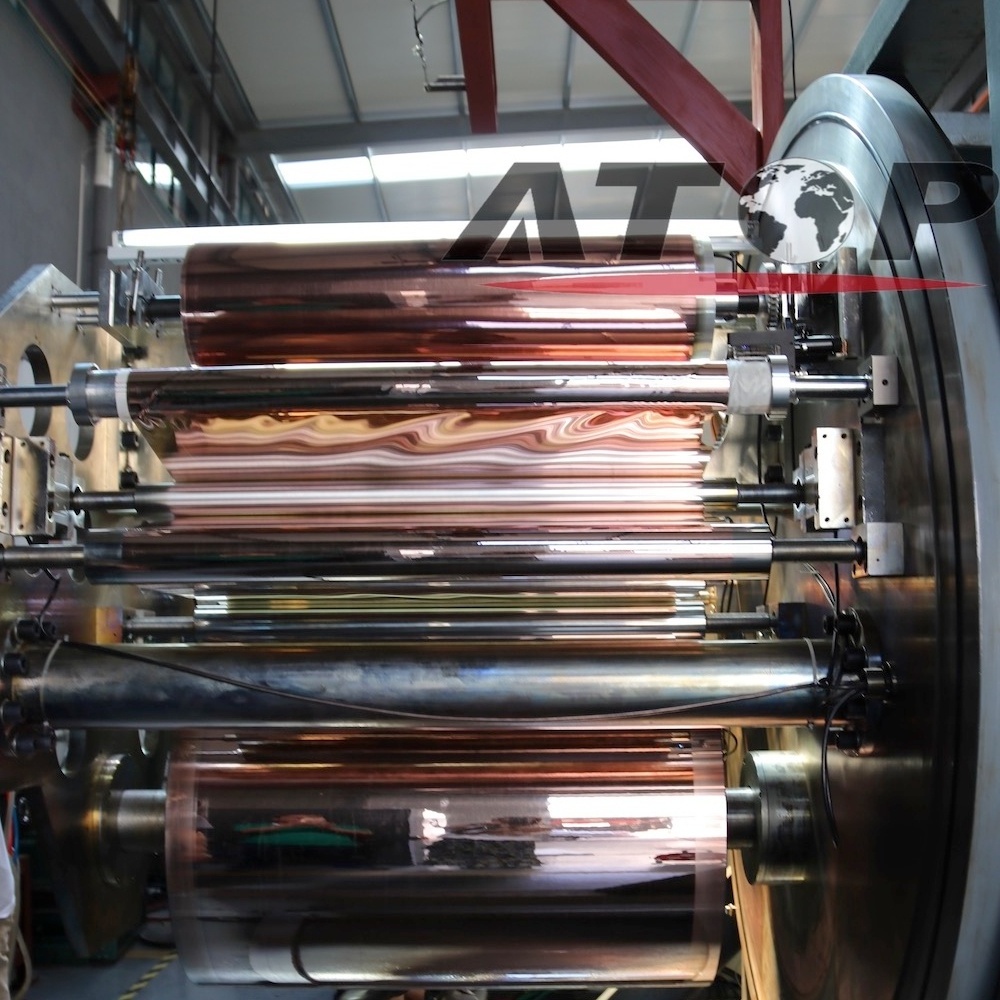

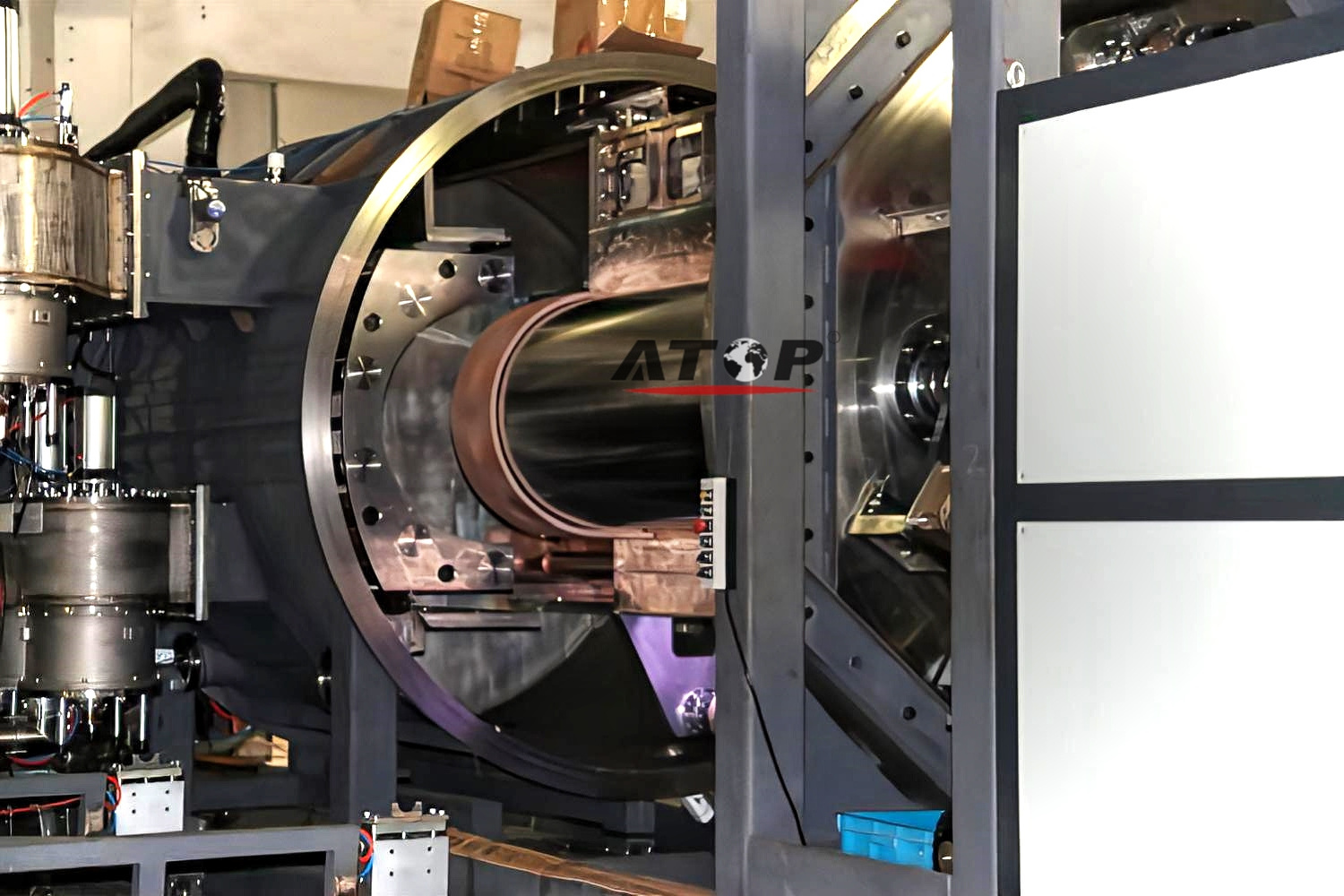

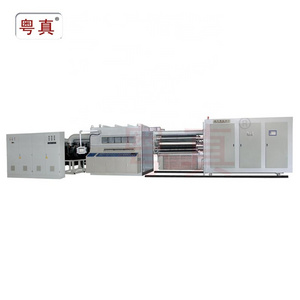

roll to roll vacuum coating, Coating Equipment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ATOP

-

Voltage:

-

380V±5% ,50Hz

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

15000

-

Technology:

-

vacuum Coating

-

Coating film:

-

metal film

-

Pressure raising rate:

-

<0.67Pa/h

-

Cycle cooling water:

-

300L/H

-

Environmental temperature:

-

about 25℃

-

Relative humidity:

-

<80%

-

Compressed air:

-

0.5~0.7Mpa

-

Limit vacuum degree:

-

8*10-4Pa

-

Application:

-

Package,Printing,Textile,Electronic industry

|

Professional vacuum coating machine factory here now. Offering vacuum coating machines as well as vacuum coating process OEM and ODM One-stop service. Please feel free to ask any questions about vacuum coating by mail to: machinery01 @atopincn.com; Whatsapp/ P: +86 15094392708

|

|

|

|

|||

|

Product name

|

Vacuum Metallizing Machine Machine For Films Flexible Packaging Laser Holographic

|

|

Vacuum Chamber Size

|

Decide according to the substrate size and output

|

|

Substrate

|

plastic, paper.etc

|

|

Coating FIlm

|

metal film,conductive film,ZnS coating, Aluminum coating

|

|

Coating colors

|

gold, rose gold,silver,brown,bronze,blue,black,white,gray etc.

|

|

Applications

|

used on package, printing, anti-counterfeiting, Textile, electronic industry and so on.

|

|

Weight

|

3Tons-18Tons accordingly

|

2. The tension system uses the digital control, high tension, constant Linear velocity, the moving speed faster.

3. Each wire-feeding unit controlled by computer motor separately. The speed can be adjusted together or separately with speed display.

4. Equipped with high standard vacuum pump system, with large vacuum pump speed, by PLC control.

5. Equipped with big capacity power source, high coating efficiency, good coating uniformity.

6. Stable operation, neatly release and loading, good coating uniformity, short production cycle, low energy consumption, easy operation and maintenance, stable performance and other more advantages .

PACKAGE:

Packed in standard exporting packing.

DELIVERY TIME:

Delivery

: 45-70 working days after the day of deposit according to machine models.

Machine acceptance inspection: we will inform the customer the test date of the machine within the delivery date. The customer can arrange the exact date to our workshop to inspect the machine. When the machine passing by the inspection, the customer pay the balance payment and we will transport the machine.

About Us

PVD coating is the major business of Atop Industry Co.,Ltd, We have more than 20 years of experience in the industry. Our factory has obtained ISO quality management system and CE certificate. 100% Strictly carry on the design, production and testing to each equipment under 1S09001: 2008 quality management system, which ensures the stability and high quality products providing to tens of thousands of customers use.

Our main products include continuous magnetron sputtering coating production line (SIO2, ITO, AZO, TCO, low-e) plane arc tooling coating machines , multifunctional intermediate frequency magnetron sputtering coating equipment, Multi-arc compound ion coating machine, optical coating machine and ion plating technology, including : unbalanced magnetron, intermediate frequency magnetron sputtering and arc evaporation source, ion source auxiliary coating and the combination of a variety of technical features. The rolling coating machine which takes the high frequency induction evaporation technology can satisfy the PET, PVC, OPP, CPP strip material, laser holographic anti-counterfeiting materials such as film, capacitors, polyester cloth and other vacuum aluminum plating and evaporation of the medium material requirements.

UP to now, our company has been serving more than thousands of customers widely in solar photovoltaic (PV), low radiation coated glass, flat panel display, semiconductor, light, hardware clock, mold, electron, food, plastics and other industries.

With stable-quality, high-efficient products and excellent customer service , Atop Industry Co.,Ltd has gained great reputation from more and more domestic and foreign customers!

Turnkey Service: including film research and equipment research, manufacturing, installation, debugging, trial production, personnel training. our company has perfect after-sales service network and more than 1o individuals experienced after-sales service team, all-round for customers solve various problems of vacuum equipment and process.