- Product Details

- {{item.text}}

Quick Details

-

Main Raw Materials:

-

Polyester

-

Level:

-

Finish Coat

-

Components:

-

Film Forming Matters

-

Surface:

-

Smooth High Glossy

-

Transport Package:

-

25kg/carton

-

Method:

-

Spray

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

CPW-7214BD

-

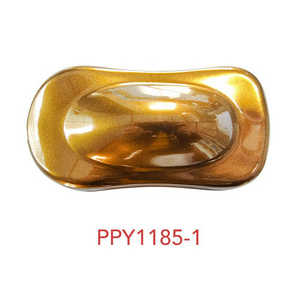

Color:

-

Dark Green

-

Main Raw Materials:

-

Polyester

-

Level:

-

Finish Coat

-

Components:

-

Film Forming Matters

-

Surface:

-

Smooth High Glossy

-

Transport Package:

-

25kg/carton

-

Method:

-

Spray

Product Description

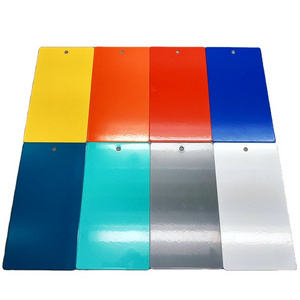

Powder Coating Appliance Powder Coating Outdoor Electrostatic Thermosetting Powder Coating

Color : According to RAL /PANTONW color card

Features: Anti-graffiti, anti-acid, anti-corrosion, anti-ultraviolet

Package: Plastic bag, 25 kg/carton

Brand: ICK Instructions: High voltage electrostatic spraying

Feature : Pollution-free green environmental protection powder coating

Main Raw Material: Epoxy, polyester, acrylic, etc.

Usage: Appliance Paint

Usage: Car Paint Usage:

Electrical Insulating Varnish

Electrical Insulating Varnish

Usage: Appliance Paint

Usage: Boat Paint

Usage: Building Coating

Usage: Car Paint

Usage: Electrical Insulating Varnish

Usage: Furniture Paint

Usage: Paper Coating

Usage: Plastic Coating

Usage: Road Marking Paint

Application Method: Spray

State: Powder Coating

Application Method: High voltage electrostatic spraying

Specification

|

Main Raw Materials

|

Polyester

|

|

Method

|

Spray

|

||

|

Appearance

|

Powder

|

|

Substrate

|

Aluminium,Steel,Stainless Steel

|

||

|

Level

|

Finish Coat

|

|

Formation Mechanism

|

Conversion Type

|

||

|

Components

|

Film Forming Matters

|

|

Curing

|

200℃*10mins

|

||

|

Expiration Date

|

1 year (below 30℃)

|

|

Trademark

|

ICK(or OEM)

|

||

|

Transport Package

|

25kg/carton

|

|

HS Code

|

3907910000

|

||

|

CUPPING TEST

|

EN ISO 1520

|

|

PASSED 5MM INDENTATION WITHOUT CRACKING

|

|

||

|

FLEXIBILITY

|

EN ISO 1519

|

|

PASSED 5MM CYLINDRICAL MANDREL BEND TEST

|

|

||

|

|

|

|

WITHOUT CRACKING

|

|

||

|

IMPACTRES RISTANCE

|

ASTMD 2794

|

|

PASSED 23 INCH-PONDS WITHOUT CRACKING

|

|

||

|

ACETIC ACID SALT SPRAY RESISTANCE

|

EN ISO 9227

|

|

MAXIMUM 16MM² INFILTRATION OVER A SCRATCH LENGTH OF 10 CM

|

|

||

|

|

|

|

AFTER 1,000HOURS ANY UNILATERAL PENETRATION SHALL NOT EXCEED 4MM

|

|

||

|

ACCELERATEDWEALTHERING

|

EN ISO 16474-3

|

|

550±20W/M²(290-800NM) TEMPERATURE 65±5°C

|

|

||

|

|

|

|

SPECIAL UV FILTER(290NM) STAY IN 18 MINUTES FOR MOIST MEDIUM AND

|

|

||

|

|

|

|

102 MINUTES FOR THE DRY MEDIUM AROUND AFTER 1,000 HOURS IRRADIATION

|

|

||

|

NATURAL WEATHERING TEST

|

EN 1SO 2810

|

|

NOCHALKING EXCELLENT GLOSS RETENTION AND COLOUR

|

|

||

|

|

|

|

STABILITY AFTER 12 MONTHS

|

|

||

|

HUMIDITY RESISTANCE

|

EN 1SO 6270-2

|

|

EXPOSURE (ANGLE OF 5° TO SOUTH ) NO INTILTRATION EXCEEDING

|

|

||

|

|

|

|

1MM BOTH SIDES OF THE SCRATCH AFTER 1,000HOURS

|

|

||

Production process

Application

Packing & Delivery

Hot Searches