- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ or customizable

-

Power:

-

30-75KW or customizable

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

36000*1200*2000mm or customizable

-

Year:

-

2022

-

Product name:

-

Stainless steel fully automatic pani puri making machine small

-

Material:

-

304 Stainless Steel

-

Color:

-

Silver

-

Function:

-

pani puri making machine

-

Raw material:

-

Potato starch, corn starch, cassava starch wheat flour etc.

-

Inverter:

-

Delta

-

Motor:

-

Siemens

-

Output:

-

100-300kg/h

-

Energy:

-

Electricity, oil, Gas

-

Advantage:

-

Easy Operation High Performance

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chenyang

-

Voltage:

-

380V/50HZ or customizable

-

Power:

-

30-75KW or customizable

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

36000*1200*2000mm or customizable

-

Year:

-

2022

-

Product name:

-

Stainless steel fully automatic pani puri making machine small

-

Material:

-

304 Stainless Steel

-

Color:

-

Silver

-

Function:

-

pani puri making machine

-

Raw material:

-

Potato starch, corn starch, cassava starch wheat flour etc.

-

Inverter:

-

Delta

-

Motor:

-

Siemens

-

Output:

-

100-300kg/h

-

Energy:

-

Electricity, oil, Gas

-

Advantage:

-

Easy Operation High Performance

Our Advantages

Products Description

|

Name

|

Stainless steel fully automatic pani puri making machine small

|

|

Raw material

|

wheat flour, potato starch, potato flour, corn starch, cassava starch, etc.

|

|

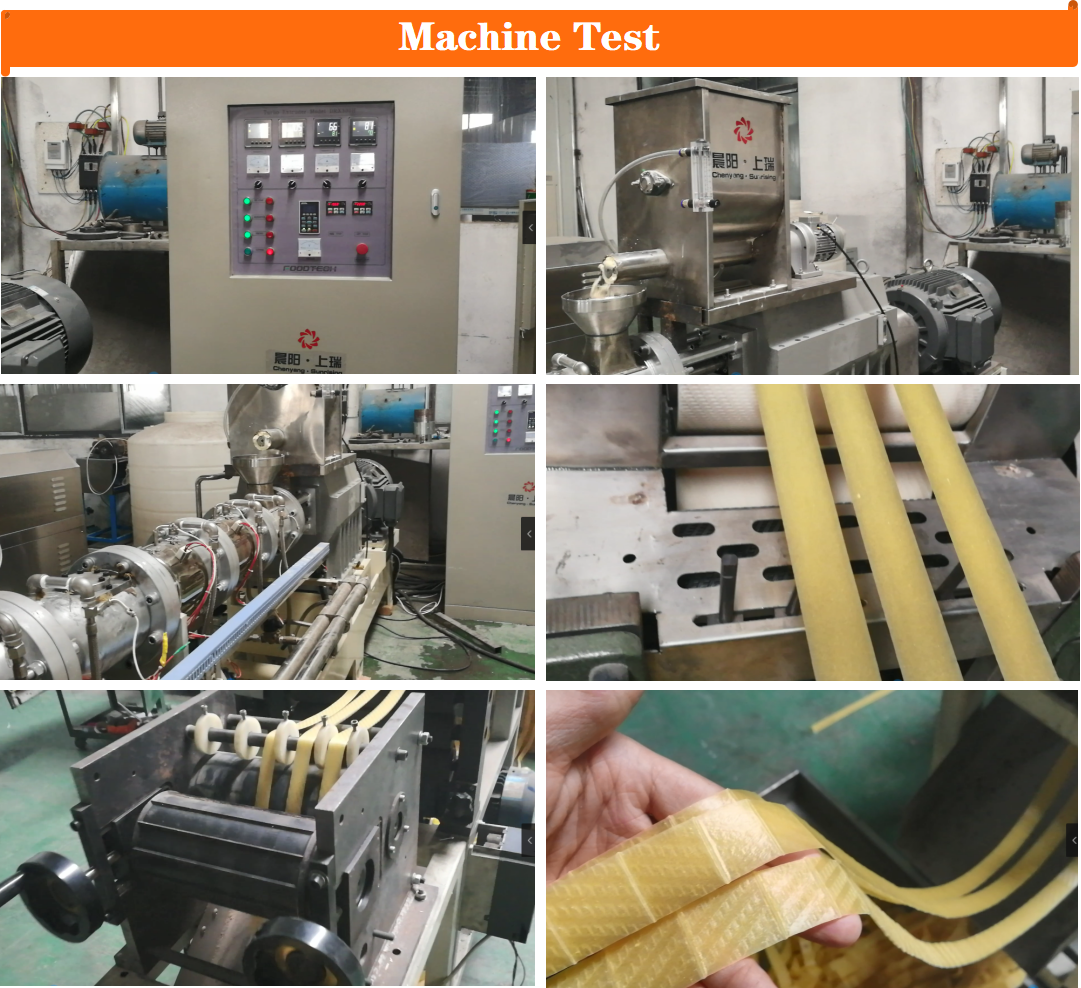

Work flow

|

Mixer--Extruder--Pulling Cutter-Compound Shaper--Roller Drum--Vibration Cooler--Hoister--Dryer--Fryer--Flavoring

|

|

Products

|

triangle bugles, potato food and other 3D Pellet with various shapes.

|

|

Machine material

|

Stainless steel 304 201 or as customer’s request

|

|

Energy

|

Electricity ,Diesel, Steam ,Gas

|

|

Advantage

|

Easy to carry, Long shelf life

|

Details

|

Name

|

Big Mixer

|

Small Mixer

|

|

Installed Power

|

7.5kw

|

4kw

|

|

Power Consumption

|

6 kw

|

3.2kw

|

|

Output

|

600kg/h

|

400kg/h

|

|

Size

|

1.4x0.7x1.4m

|

1x0.6x1.2m

|

|

Name

|

Double/Single Screw Extruder

|

|

Model

|

CY75,CY100

|

|

Main Motor Power

|

55-75kw,30kw

|

|

Screw Diameter

|

75mm,100mm

|

|

Output

|

100 kg/h-300kg/h

|

|

Name

|

Pulling Cutter

|

|

Heating Method

|

Electricity

|

|

Power

|

1.5kw

|

|

Output

|

250kg/h

|

|

Name

|

Compound Cutter

|

|

Heating Method

|

Electricity

|

|

Power

|

2.2kw

|

|

Output

|

300kg/h

|

|

Size

|

1300X800X1300mm

|

|

Name

|

Dryer

|

|

Model

|

CYK-III,CYK-IV,CYL-IV,etc

|

|

Heat Method

|

electricity,gas

|

|

Output

|

120 kg/h-350kg/h

|

|

Material

|

stainless steel

|

|

Name

|

Double Roller Flavor Machine

|

|

Driving power

|

4.8kw

|

|

Heating Power

|

9kw

|

|

Output

|

250kg/h-350kg/h

|

|

Size

|

6500x2000x2800mm

|

|

Main Accessories

|

Function

|

|

Anti-blocking feeder

|

Makes sure the even feeding and stable discharge of materials.

|

|

Double shaft preconditioner

|

Enables the materials stay longer in the preconditioner and evenness in precondtioning, improves the precure degree and increases the capacity.

|

|

Gearbox

|

Processed by internationally advanced process technology, ensuring the machines run in long time without malfunction.

|

|

Lubrication and cooling system

|

Adopts refined filtration forced cooling, creating best working conditions for the bearings.

|

|

The feeding system

|

adopts double spiral forced feeding, feeding uniformly and widely.

|

|

The screw

|

Segmented combined screw, suitable for a wide range of raw materials. With self-cleaning function.

|

|

The rotary cutting device

|

Adopts a suspended mold (knife) assembly and a linear bearing tool adjusting device to adjust the tool safely, accurately and quickly.

|

Control Cabinet:

The control part uses centralized PLC touch screen control, visualized parameters.

Key highlights of Chenyang dryer:

◆ Unique structure, high utilization rate of heat energy, high efficiency,environmental protection and

energy saving;

◆ Circulation drying process, the moisture difference of the dried product is small, and the drying

effect is good.

◆ Horizontal overall layout, simple structure, reliable control, convenient and intuitive operation.

◆ The frequency motor controls the speed of the mesh belt, and the drying quality can be adjusted

flexibly.

◆ The food contact part is all stainless steel, corrosion resistant.

◆ Energy can be gas heating and steam heating.

Hot Searches