- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2450*2100*3400mm

-

Power (kW):

-

22 kW

-

Weight (KG):

-

2800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Application:

-

For tire retreading

-

Control system:

-

Adopt four-axis servo

-

Structure:

-

With sidewall brusher

-

Precision:

-

Higher

-

Marketing Type:

-

New Product 2021

-

Certification:

-

ISO/CE/SGS

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

cgy

-

Voltage:

-

210v,220v,240v,380v,400v,415v,440v

-

Dimension(L*W*H):

-

2450*2100*3400mm

-

Power (kW):

-

22 kW

-

Weight (KG):

-

2800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Application:

-

For tire retreading

-

Control system:

-

Adopt four-axis servo

-

Structure:

-

With sidewall brusher

-

Precision:

-

Higher

-

Marketing Type:

-

New Product 2021

-

Certification:

-

ISO/CE/SGS

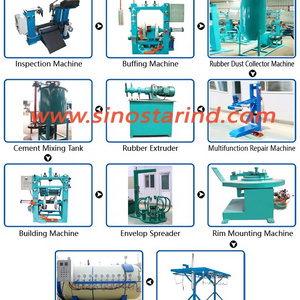

Expandable rim CNC tire buffing machine with automatic thickness measurement device

Function

Expandable rim CNC buffer can rasp multiple arcs and lines on the same tyre, also has larger range of buffing radius, so it is suitable for super-tyre buffing. Use the RASP to buff crown and shoulder, if adding device to buff sidewall, so it is suitable for wing tread and hot retreading.The key buffing index (like symmetry of arcs, accuracy of buff radius ,roughness of buff texture, thickness accuracy of undertread rubber and the buff surface are not scorched ) can be controlled exactly and stably.

Main technical parameters

Maximum diameter of tire: 1300mm

Maximum weight of tire: 136kg

Production efficiency: 4-6min/tire

Main motor power: 22kw

Power supply: 380V,50Hz

Numerical control system: SIEMENS

Low pressure electronics: SCHNEIDER

Pneumatic component: JPC of FESTO

Air supply: >0.8Mpa , gas pipe size: 1/2 inch

Noise :<80 Decibel

Overall size(L*W*H): 2450*2100*3400mm

Weight: 2800kg

Performance Description

1. Adopt four-axis servo control system, precise ball screw and linear guideway to keep buffing contour accurate.

2. Buff crown and shoulder, can rasp multiple arcs on the same tire.

3. Directly choose buffing contour on screen based on tire brand, size and serial number.

4. Set or amend buffing contour easily by yourself ,no need writing program.

5. Set the buffing circumference, machine will stop automatically and the buffing circumference can be saved in buffing contour group.

6. Set the amount of feed on screen and it will be controlled by servo motor precisely.

7. The automatic frequency conversion and speed control of tire rotate spindle to ensure the roughness of buff texture.

8. Set the RASP work position automatically.

9. Automatic cooling water spraying device ,avoid buff surface scorching.

10. Control the inflated pressure automatically and if over pressure it has the function of warning and exhausting automatically.

11. Adopt high precision expandable rim 20-22.5-8.5 inch

12. Information interface realizes network transmission and remote diagnosis and maintenance.

13. The precise moving unit equipment with sealing dust cover.

14. Equipped with a tire lifter.

Our packing way: Export standard (wooden package ),or according to your requirement.

Our Services :

1. We will design,manufacture,install and test the machines according to customers' requirement. Relevant personnel training for customers,ensure that customers fully grasp the use and maintenance of technology.

2 .Our service department listen to customers' feedback at any time and provide spare parts timely.

Welcome to visit our factory and we can show you the machine in working condition:

If our products win your interest, please send us inquires and we

will provide detailed information for you. We can also non-standard make machines according to your request.