Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

65 rpm

-

Place of Origin:

-

Jiaozhou City, Qingdao, China

-

Brand Name:

-

TONGSAN HEGU

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

22mx4mx4m

-

Power (kW):

-

37

-

Weight:

-

3500 KG

-

Product:

-

PE WPC profiles

-

Max Product Width:

-

250mm

-

Calibrating Platform Length:

-

6000mm

-

Motor Brand:

-

Siemens

-

Inverter:

-

ABB

-

Temperature controller:

-

Omron

-

Low-Voltage breaker:

-

Siemens

-

Certification:

-

CE ISO9001

-

After-sales Service Provided:

-

Video technical support, Free spare parts,Training

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Unapplicable

-

Screw diameter (mm):

-

65/132

-

Screw Speed (rpm):

-

65 rpm

-

Place of Origin:

-

Jiaozhou City, Qingdao, China

-

Brand Name:

-

TONGSAN HEGU

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

22mx4mx4m

-

Power (kW):

-

37

-

Weight:

-

3500 KG

-

Product:

-

PE WPC profiles

-

Max Product Width:

-

250mm

-

Calibrating Platform Length:

-

6000mm

-

Motor Brand:

-

Siemens

-

Inverter:

-

ABB

-

Temperature controller:

-

Omron

-

Low-Voltage breaker:

-

Siemens

-

Certification:

-

CE ISO9001

-

After-sales Service Provided:

-

Video technical support, Free spare parts,Training

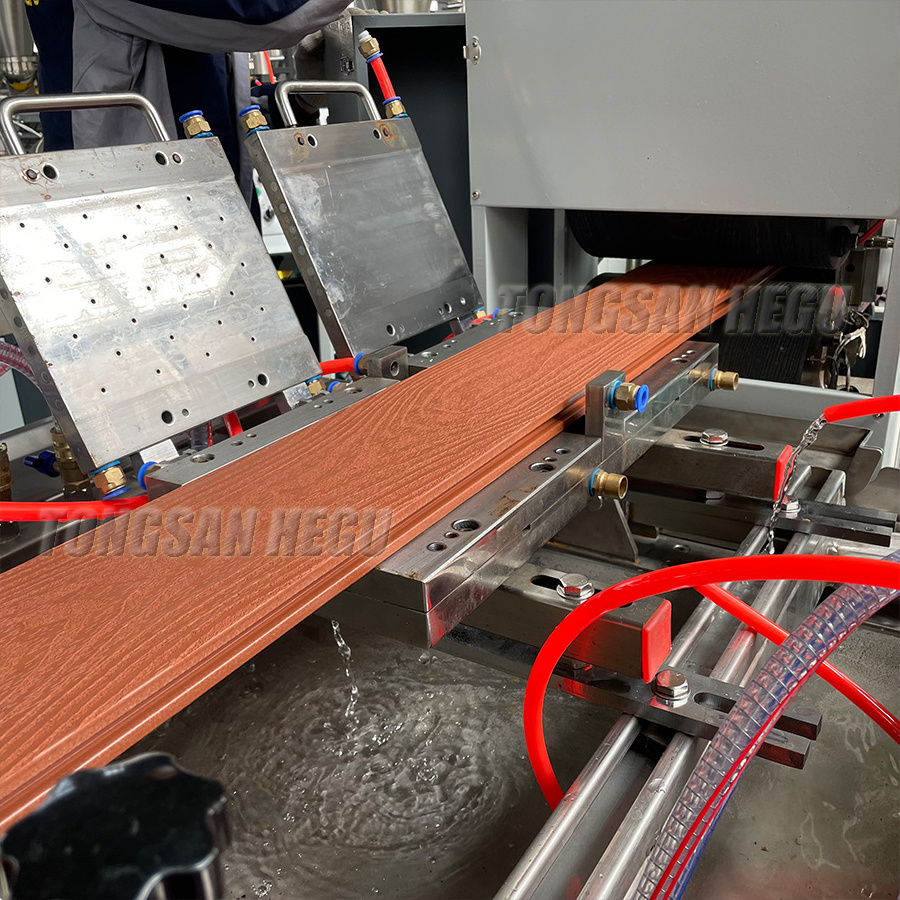

Wood Plastic Composite products extrusion line and installation workshop

Main products

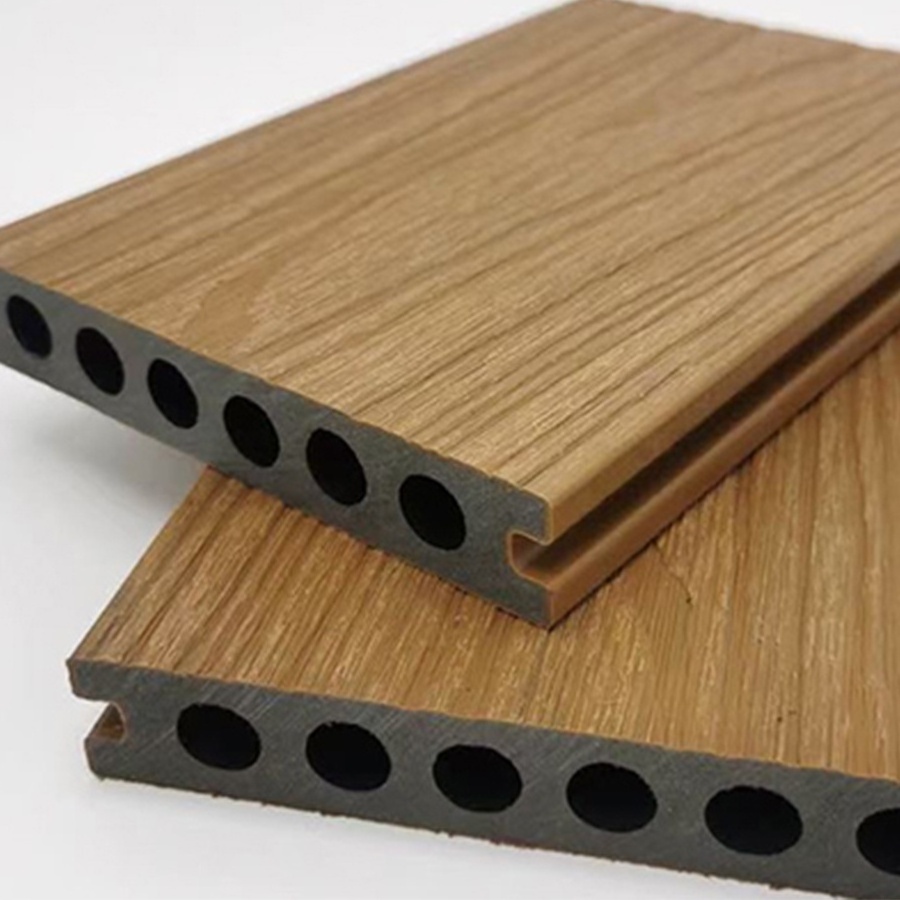

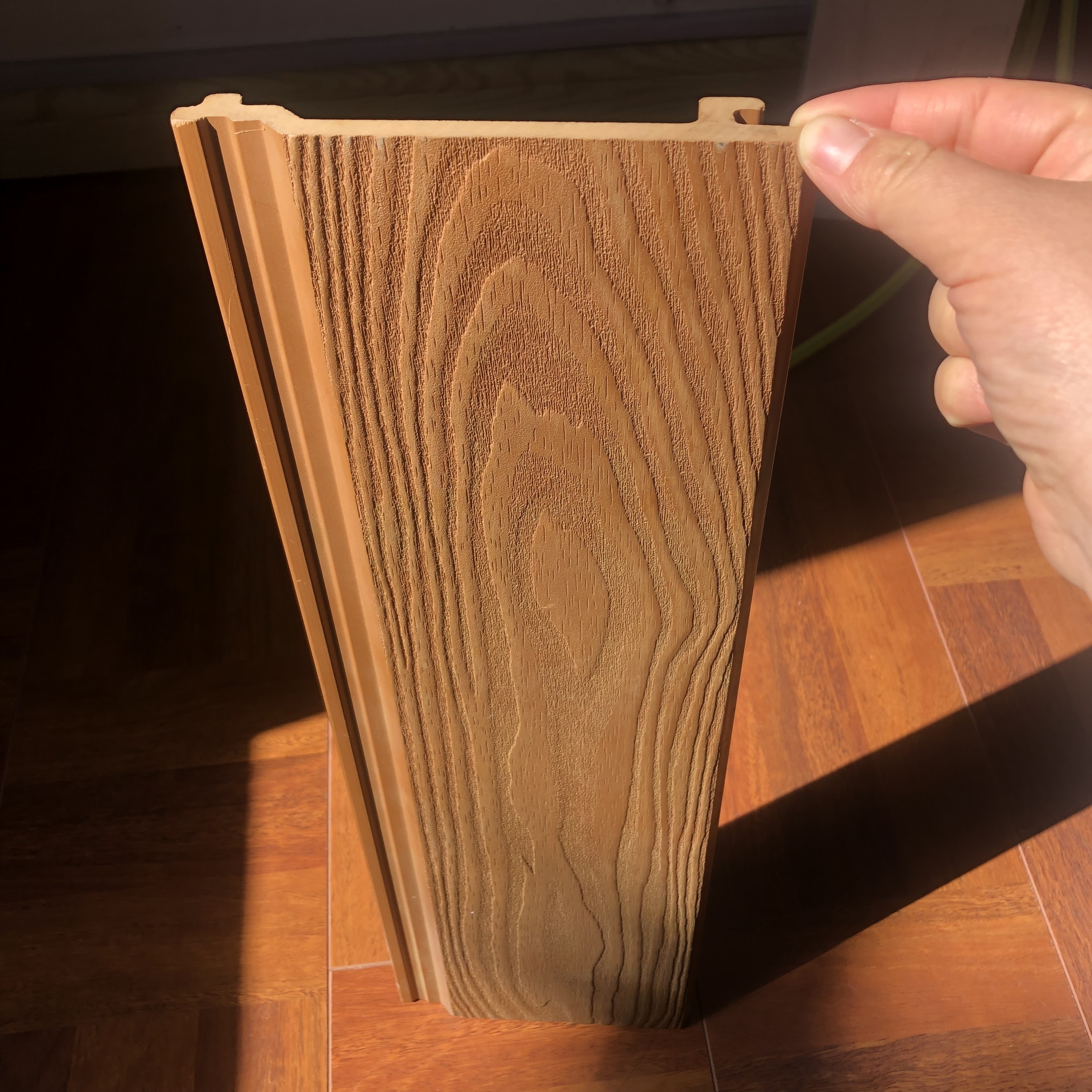

(1)PE WPC profile extrusion line, which for making outdoor wpc decking,fence, post, pallet, chair, wall panel and ceiling panel etc.

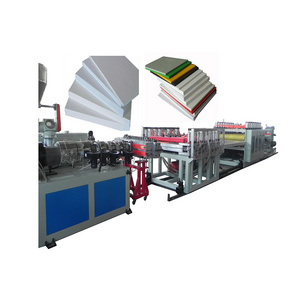

(2)PVC or WPC profile extrusion line, which for making window and door frames, indoor wall panel and ceiling panel etc.

(3)PVC or WPC door panel extrusion line.

(4)Free foam board and skinned foam board extrusion line.

(1)PE WPC profile extrusion line, which for making outdoor wpc decking,fence, post, pallet, chair, wall panel and ceiling panel etc.

(2)PVC or WPC profile extrusion line, which for making window and door frames, indoor wall panel and ceiling panel etc.

(3)PVC or WPC door panel extrusion line.

(4)Free foam board and skinned foam board extrusion line.

(5)Plastic and PE WPC granules extrusion line.

PP PE WPC profile extrusion line

PE WPC profile extrusion line for making outdoor WPC decking, fence, post, pallet, chair, wall panel etc.The extrusion line includes conical twin screw extruder, calibration platform, cutting machine with dust collection device, product stacker. Through mixing, granulating, extruding, embossing, sanding, brushing etc processing steps, make PE WPC profiles can be similar with natural wood in appearance and feel.

|

Extruder Model

|

Max. product width

|

Extrusion Capacity

|

Power

|

|

SJMS-65/132

|

250mm

|

120-180kg/h

|

37kw

|

PP PE WPC Application

PVC WPC profile extrusion line

PVC WPC profile extrusion line for making window and door frames, photo frames, indoor wall panel and ceiling panel etc. The extrusion line includes conical twin screw extruder, calibration platform, Hauling off and cutting machine with dust collection device, product stacker.

|

Extruder model

|

Max. product width

|

Extrusion Capacity

|

Power

|

|

SJMS-65/132

|

250mm

|

120-180kg/h

|

37kw

|

|

SJMS-80/156

|

600mm

|

250-380kg/h

|

75kw

|

PVC WPC door extrusion line

We can provide the turnkey project for making complete finished door from raw material.

|

Extruder model

|

Max. door width

|

Extrusion capacity

|

Motor power

|

|

HGMSMB-80/156

|

800mm

|

350-380kg/h

|

75kw

|

|

HGMSMB-92/188

|

1200mm

|

500-550kg/h

|

110kw

|

PVC WPC Foam board extrusion line

The extrusion line includes conical twin screw extruder, calibration platform, cooling bracket, hauling off machine, cutter and stacker. The foam board can be used for making furniture, wall panel etc.

|

Extruder model

|

Board thickness

|

Board width

|

Extrusion capacity

|

Motor power

|

|

SJMSB-80/156

|

5-18mm

|

1220mm

|

350-380kg/h

|

75kw

|

|

SJMSB-80/173

|

3-30mm

|

1220mm

|

420-450kg/h

|

90kw

|

|

SJMSB-92/188

|

20-40mm

|

1220mm

|

500-550kg/h

|

110kw

|

Company Overview

Our company

built from 1997, total building size is 8048㎡. We are professional plastic and WPC products extrusion line manufacturer. We already have 26 years experiences in this industry. We can supply granulating machines, profiles extrusion line, pipe extrusion line, sheet extrusion line, board extrusion line and auxiliary machines. Our company could provide turn-key project as feasibility report, workshop planning, technical support, testing, installation, training and after-sale service. For more than 20 years, we have provided thousands of production lines for customers in more than 50 countries. Our equipment to create the greatest value for customers is our constant pursuit. Our engineers adhere to the original intention of doing every equipment component carefully, and only deliver efficient and stable equipment for customers. We live up to your every trust.

1. WHY CHOOSE US

Our company could supply turn-key project as feasibility report, workshop planning, technical support , testing,

installation, training and after-sale service. We would like to supply high-class products and satisfy every customer's needs. Our equipment to create the greatest value for customers.

2.WHAT SERVICES DO WE OFFER

2.1 Pre-sale communication

2.2 Design proposal &signature confirmation

2.3 Customized production

2.4 Test machine before shipment

2.5 Package & delivery

2.6 Engineer installation

2.7 Training operator

2.8 Technical support

3.PAYMENT TERMS

30% of total amount to be paid by T/T as down payment.

The balance(70% of total amount) to be paid before delivery by T/T or irrevocable L/C by payment (at sight).

4.DELIVERY CONDITIONS

4.1 delivery condition: FOB Qingdao port.

4.2 delivery term: within 60 working days after receipt of down payment, the seller should inform the buyer to do inspection. The seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

4.3 supervision of loading: the seller should inform the buyer exacting loading time, the buyer should arrange for supervision of loading!

5.WARRANTY TERMS

5.1 warranty period: 12 months, starting from the first day of running machines in customer's warehouse.

5.2 seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment warranty period.

5.3 lifelong service: the seller should provide lifelong service for the sold goods, the buyer pay for needed spare parts after

the 12 months warranty terms.

6.INSPECTION

The seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods. The seller undertake the material cost for the machine inspection in seller's factory. The buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third part to come to seller's factory to do the inspection work.

7.INSTALLATION

The seller should send engineer to buyer's factory for machine installation and testing. Buyer should undertake all the traveling costs for engineer (such as hotel, air tickets and food) and engineer salary 120 USD/day/engineer. If engineers can't go to customer's factory for machine installation, the seller should provide online video calling service to guide customer for machine installation and running.

installation, training and after-sale service. We would like to supply high-class products and satisfy every customer's needs. Our equipment to create the greatest value for customers.

2.WHAT SERVICES DO WE OFFER

2.1 Pre-sale communication

2.2 Design proposal &signature confirmation

2.3 Customized production

2.4 Test machine before shipment

2.5 Package & delivery

2.6 Engineer installation

2.7 Training operator

2.8 Technical support

3.PAYMENT TERMS

30% of total amount to be paid by T/T as down payment.

The balance(70% of total amount) to be paid before delivery by T/T or irrevocable L/C by payment (at sight).

4.DELIVERY CONDITIONS

4.1 delivery condition: FOB Qingdao port.

4.2 delivery term: within 60 working days after receipt of down payment, the seller should inform the buyer to do inspection. The seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

4.3 supervision of loading: the seller should inform the buyer exacting loading time, the buyer should arrange for supervision of loading!

5.WARRANTY TERMS

5.1 warranty period: 12 months, starting from the first day of running machines in customer's warehouse.

5.2 seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment warranty period.

5.3 lifelong service: the seller should provide lifelong service for the sold goods, the buyer pay for needed spare parts after

the 12 months warranty terms.

6.INSPECTION

The seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods. The seller undertake the material cost for the machine inspection in seller's factory. The buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third part to come to seller's factory to do the inspection work.

7.INSTALLATION

The seller should send engineer to buyer's factory for machine installation and testing. Buyer should undertake all the traveling costs for engineer (such as hotel, air tickets and food) and engineer salary 120 USD/day/engineer. If engineers can't go to customer's factory for machine installation, the seller should provide online video calling service to guide customer for machine installation and running.

Hot Searches