20 thickness. More important, the ceramic fiber heater can work around the clock.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Product Name:

-

Furnace Chamber Heater With Metal Shell

-

Classification Temperature:

-

1100-1800c

-

Chemical Component:

-

AL2O3+SIO2

-

Heating Elements:

-

Fe-Cr-AI-Mo Wire / Sic / Mosi2 Rod

-

Character:

-

Low Thermal Conductivity

-

Usage:

-

Heat Treatment / Creation of Thermal Fields

-

Application:

-

Photovoltaic / Semiconductor / Other Heating Equipment

-

Chamber Size:

-

Customizable

-

Power:

-

Customizable

-

Voltage:

-

Customizable

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

SYN

-

Model Number:

-

SYN-1200-1800

-

Place of Origin:

-

Henan, China

-

Product Name:

-

Furnace Chamber Heater With Metal Shell

-

Classification Temperature:

-

1100-1800c

-

Chemical Component:

-

AL2O3+SIO2

-

Heating Elements:

-

Fe-Cr-AI-Mo Wire / Sic / Mosi2 Rod

-

Character:

-

Low Thermal Conductivity

-

Usage:

-

Heat Treatment / Creation of Thermal Fields

-

Application:

-

Photovoltaic / Semiconductor / Other Heating Equipment

-

Chamber Size:

-

Customizable

-

Power:

-

Customizable

-

Voltage:

-

Customizable

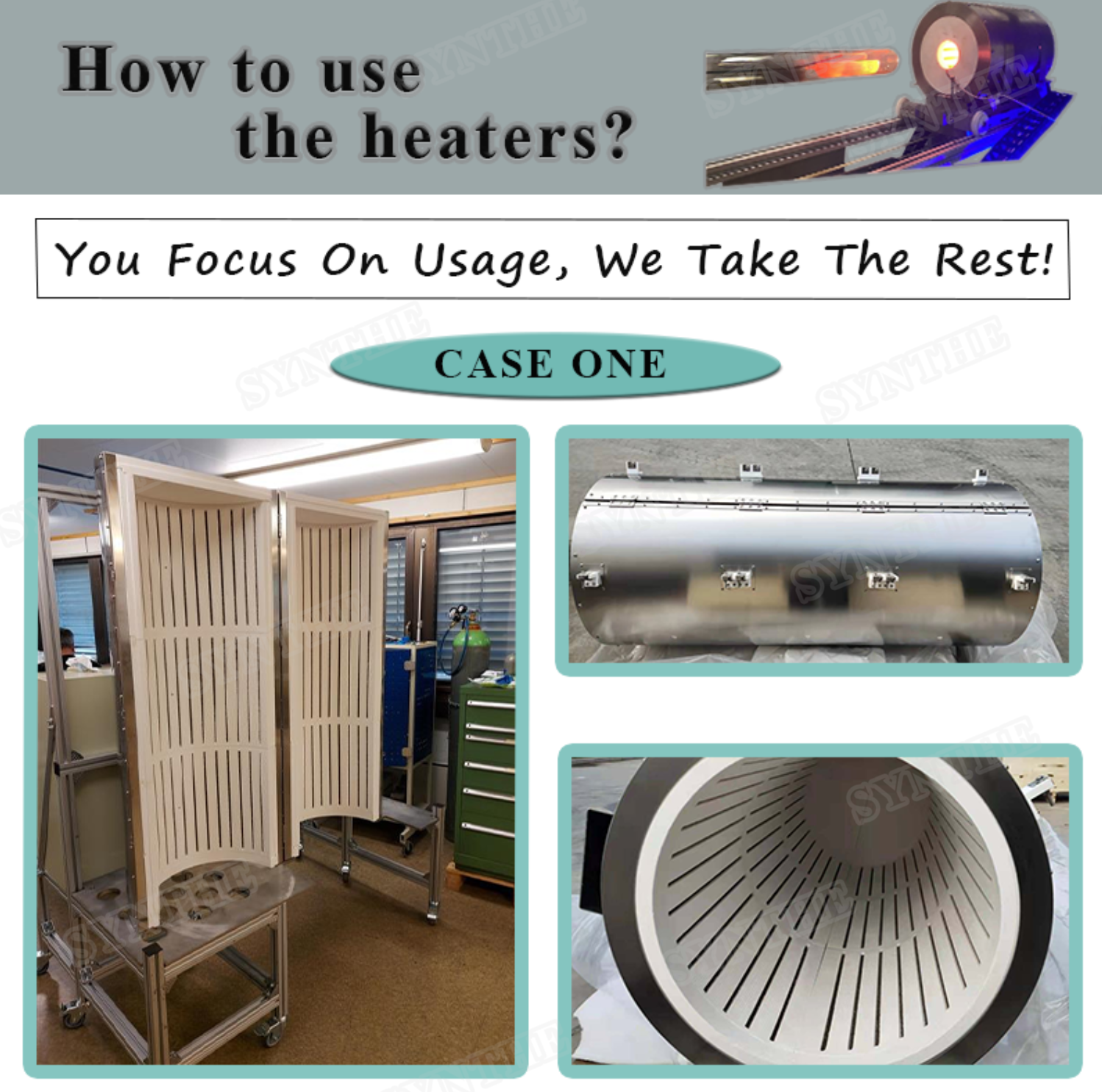

This heater is a special structure with the top closed and the bottom opened. In order to compensate the heat loss with electrical heating ,the customer uses our ceramic fiber heater as a heat shield suspended vertically and heated.

In this case, the customer uses the heater as a sliding heater to quickly achieve the requirements for heating and cooling the test sample. This usage makes the heater operation more convenient and greatly improves the heating efficiency.

20 thickness. More important, the ceramic fiber heater can work around the clock.

These heaters will be hung together vertically for use to heat SS310 tubes. And them provide temperature field environment for SS310 tube innteral sample's chemical reaction.

Our ceramic fiber heaters have various sizes and shapes, they are also used much as the heating oven on various test machines,supply the high temperature field environment. Welcome to join us in exploring more uses for heaters.

Products Description

Ceramic fiber heaters are also known as ceramic fiber heating modules, oven,etc., configuring the outer metal shell which can be used directly. It adopts the integral shape of ceramic fiber materials by vacuum suction methods,which has good fire resistance and heat insulation effect. Different heating elements can be selected for different temperature requirements. It is usually used to provide heat for the experimental objects. Compared with the traditional stove, it focus on the heating only, it has more

extensibility, with more optional shapes, controllable temperature uniformity, as well as a simple structure and convenient operation. Different experiments require customers to have different uses, and we are always exploring more ways to use the heater. Welcome to join us!

extensibility, with more optional shapes, controllable temperature uniformity, as well as a simple structure and convenient operation. Different experiments require customers to have different uses, and we are always exploring more ways to use the heater. Welcome to join us!

|

Technical Parameters

|

|

|

|

|||

|

Heaters with Metal Shell

|

Split Open Type

|

Closed Round Type

|

Remark

|

|||

|

Resistance Wire Distribution

|

Tangent type

|

Slot wire half-exposed type

|

As your demands

|

|||

|

Heating Zone

|

Subject to the demands

|

|

|

|||

|

Size

|

Subject to the demands

|

|

|

|||

|

Usage

|

As a simple tube furnace

|

As a heater directly

|

|

|||

|

Heating Element

|

Resistance Wire/Sic Rods/Mosi2 Heating Elements

|

|

|

|||

|

Working Temp.

|

1100-1700℃

|

|

|

|||

|

Note:

We have various styles and models as case references and provide design and customization, welcome to contact us!

|

|

|

|

|||

- HK2017 Heat Treatment Congress Held in Koln,Germany

- THERMPROCESS 2019 Held in Dusseldorf/Germany

We have participated in many international exhibitions related to refractory materials, and have rich industry experience inrefractory materials. We also met many partners in the exhibition and provided them with good designs and products. Contact us!

- THERMPROCESS 2019 Held in Dusseldorf/Germany

We have participated in many international exhibitions related to refractory materials, and have rich industry experience inrefractory materials. We also met many partners in the exhibition and provided them with good designs and products. Contact us!

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

The company has obtained the "High-tech enterprise", "Private enterprise of technology", and other awards successively. Currently,it has eight new utility patents, and more other patents of invention and other new utility patents are in the process of application.

Package:

To ensure that customers receive the products without any damage, we pack the stove in three layers. First, the stove is wrappedin clear plastic paper, and then the gaps are filled with Styrofoam. Finally packed in wooden boxes and reinforced with steel straps.

Shipping:

1. By express, such as DHL, UPS, FEDEX, etc. It usually takes 3-4 days to arrive.

2. It usually takes 5-7 days to arrive by air to the air port.

3. By sea to seaport, it usually takes 15-30 days to arrive. (depending on the voyage)

4. If your delivery time is urgent, we suggest you choose express or air freight.

5. If it is not very urgent, we recommend you to choose sea freight,which is very cheap.

3. By sea to seaport, it usually takes 15-30 days to arrive. (depending on the voyage)

4. If your delivery time is urgent, we suggest you choose express or air freight.

5. If it is not very urgent, we recommend you to choose sea freight,which is very cheap.

Q:Can you customize a product without a design solution?

A:We have a professional team of designers who can provide design solutions and process according to customer requirements for equipment.

Q:How to ensure the quality of products?

A:If the products are not conform to customer samples or have quality problems, our company will be responsible to make compensation for it.

Q:How long will it take to ship?

A:Generally 20-40 days, depending on your specific requirements for equipment.

Q:Are we unprofessional in the operation and installation of your machine?

A:We will provide product instructions and installation instructions, and if necessary, we can provide video instructions for installation.Also, we have professional engineers who can solve all problems.

Q:How to ship?

A:We support sea, air, rail transportation, etc., you can choose according to your needs. Of course you can also arrange the transport yourself.

Q:How to ensure the quality of products?

A:If the products are not conform to customer samples or have quality problems, our company will be responsible to make compensation for it.

Q:How long will it take to ship?

A:Generally 20-40 days, depending on your specific requirements for equipment.

Q:Are we unprofessional in the operation and installation of your machine?

A:We will provide product instructions and installation instructions, and if necessary, we can provide video instructions for installation.Also, we have professional engineers who can solve all problems.

Q:How to ship?

A:We support sea, air, rail transportation, etc., you can choose according to your needs. Of course you can also arrange the transport yourself.

Hot Searches