- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

914*700*900

-

Weight:

-

205 KG

-

Marketing Type:

-

New Product

-

After-sales Service Provided 1:

-

Video technical support

-

After-sales Service Provided 2:

-

Field installation, commissioning and training

-

After-sales Service Provided 3:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

feeding density:

-

0-50%

-

feeding size:

-

0-5mm

-

concentrate weight:

-

10-20KG

-

gold centrifugal concentrator:

-

centrifugal seperating equipment centrifug

-

Certification:

-

ISO CE

Quick Details

-

Production Capacity:

-

8-12T/H

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

914*700*900

-

Weight:

-

205 KG

-

Marketing Type:

-

New Product

-

After-sales Service Provided 1:

-

Video technical support

-

After-sales Service Provided 2:

-

Field installation, commissioning and training

-

After-sales Service Provided 3:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

feeding density:

-

0-50%

-

feeding size:

-

0-5mm

-

concentrate weight:

-

10-20KG

-

gold centrifugal concentrator:

-

centrifugal seperating equipment centrifug

-

Certification:

-

ISO CE

gold dust separator machine Nelson gold centrifuge for sale

still now ,jxsc mining machinery factory have exported to more than 40 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, SouthAfrica, Zimbabwe, Sudan, Ghana, Congo, Morocco, India, Indonesia, Malaysia, Philippines, NorthKorea, Mongolia, Vietnam, Thailand etc

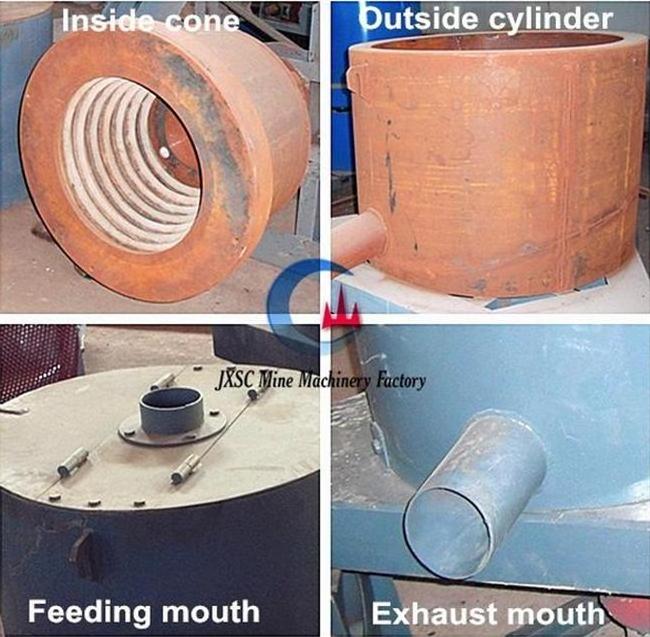

large capacity centriuge machine is a relatively new type of gravity concentration apparatus. The machines utilize the principles of a centrifuge to enhance the gravitational force experienced by feed particles to effect separation based on particle density. The key components of the unit are a cone shaped "concentrate" bowl, rotated at high speed by an electric motor and a pressurized water jacket encompassing the bowl. Feed material,typically from a ball mill discharge or cyclone underflow bleed, is fed as a slurry toward the center of the bowl from above.The feed slurry contacts the base plate of the vessel and due to its rotation, is thrust outward.The outer extremities of the concentrate bowl house a series of ribs and between each pair of ribs is a groove. During operation the lighter material flows upward over the grooves and heavy mineral particles (usually of economic value) become trapped within them. Pressurized water is injected through a series of tangential water inlets along the perimeter of each groove to maintain a fluidized bed of particles in which heavy mineral particles can be efficiently concentrated.

large capacity centriuge machine was patented in China. It is an efficient equipment for recovering free gold in all particle size ranges,specially for recovery of fine gold which is lost during the operation of the gravitational concentrators(sluice boxes and jigs). It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation, and recover gold from the old tailings.

Application shows that the recovery can be as high as 99%, and the concentrating ratio is up to 1,000 times. In recovering the natural gold in lode ore with size -0.074mm, the gold is up to 98%, For 0.004mm in particle size, the gold recovery is 97%.

Feature of gold centrifuge

High concentrating ratio and high recovery

Steady recovery performance;

Center discharge design for fast,secure concentrate removal;

Environmentally friendly(requires no chemical additives or reagents);

Low water and electricity requirements;

Low production costs, durable wear parts, minimal maintenance requirements;

Compact design requiring less space, easy merged into the existing mining processing;

Quick payback on investment, typically lass than half year

main parameter of

gold centrifuge

|

Model |

STLB20 |

STLB30 |

STLB60 |

STLB80 |

|

|

Capacity (T/h) |

0-0.6 |

2-3 |

8-12 |

40-45 |

|

|

Fluidization Water Required (m 3 /h) |

2-3 |

3-5 |

7-10 |

30-36 |

|

|

Slurry Water Required (m 3 /h) |

1.5-4 |

5-7 |

8-12 |

40-45 |

|

|

Feeding Density (%) |

0-50 |

0-50 |

0-50 |

0-50 |

|

|

Feeding Size (mm) |

0-3 |

0-3 |

0-5 |

0-5 |

|

|

Concentration Cleaning Up Cycle |

Vein gold 1-3 Hours Placer gold:2-6 Hours |

||||

|

Concentrate Weight (Kg) |

2 |

3-5 |

10-20 |

40-50 |

|

|

Power Requirements (Kw) |

0.75 |

1.5 |

4 |

11 |

|

|

Weight (Kg) |

205 |

380 |

1100 |

2300 |

|

|

Dimensions (mm) |

914×700×900 |

1160×885×1165 |

1820×1450×1700 |

2520*1900*20 |

|

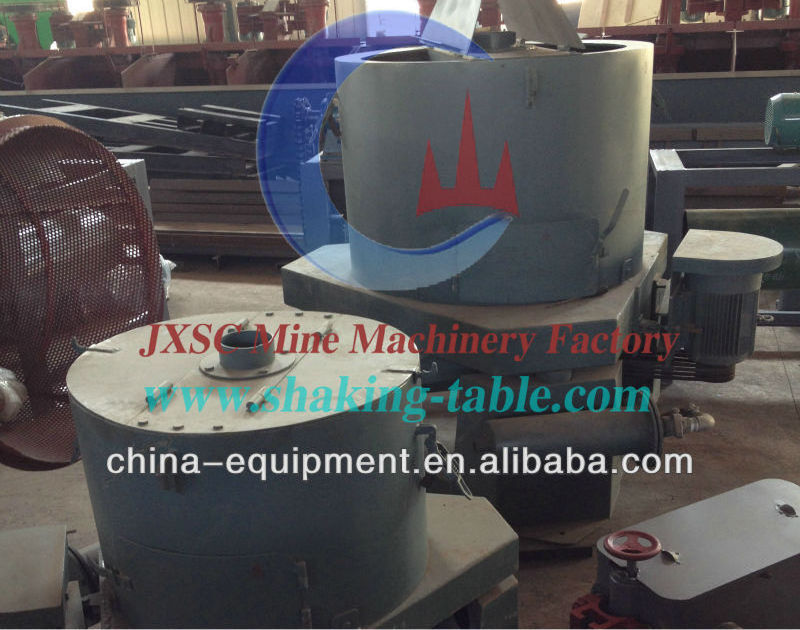

gold centrifuge photo

gold centrifuge user site and structure diagram

Customer visit JXSC mining machinery factory for centrifugal machine

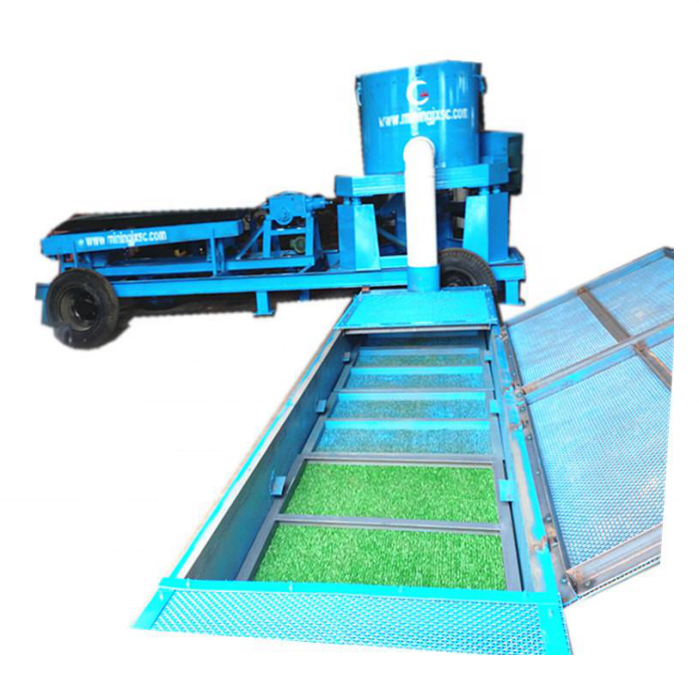

JXSC mining machinery factory other hot selling machine

Any other question,Please feel free to contact stanley