- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

12-20

-

Air Pressure(MPa):

-

3430 MPa

-

Sheet Thickness(mm):

-

1 - 5 mm

-

Heating Power (kW):

-

100 kW

-

Air Comsumption(L/min):

-

0 L/min

-

Water Comsumption(L/min):

-

0 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FUSHI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

22*6*2.8m

-

Weight (T):

-

28 T

-

Power(KW):

-

160

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Foaming Machine, Vacuum Forming

-

Production efficiency:

-

3 - 5 seconds/mould

-

Forming pressure:

-

20t (adjustable)

-

efficiency:

-

3 - 5 seconds/mould

-

After Warranty Service:

-

Spare parts, Video technical support, Online support

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Max.Forming Height(mm):

-

60 mm

-

Forming Width (mm):

-

1100 mm

-

Forming Length (mm):

-

1450 mm

-

Production Speed(Cycles/min):

-

12-20

-

Air Pressure(MPa):

-

3430 MPa

-

Sheet Thickness(mm):

-

1 - 5 mm

-

Heating Power (kW):

-

100 kW

-

Air Comsumption(L/min):

-

0 L/min

-

Water Comsumption(L/min):

-

0 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FUSHI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

22*6*2.8m

-

Weight (T):

-

28 T

-

Power(KW):

-

160

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Foaming Machine, Vacuum Forming

-

Production efficiency:

-

3 - 5 seconds/mould

-

Forming pressure:

-

20t (adjustable)

-

efficiency:

-

3 - 5 seconds/mould

-

After Warranty Service:

-

Spare parts, Video technical support, Online support

-

Marketing Type:

-

Hot Product 2021

Model Number :FS-YTB1100x1450

Brief introduction:

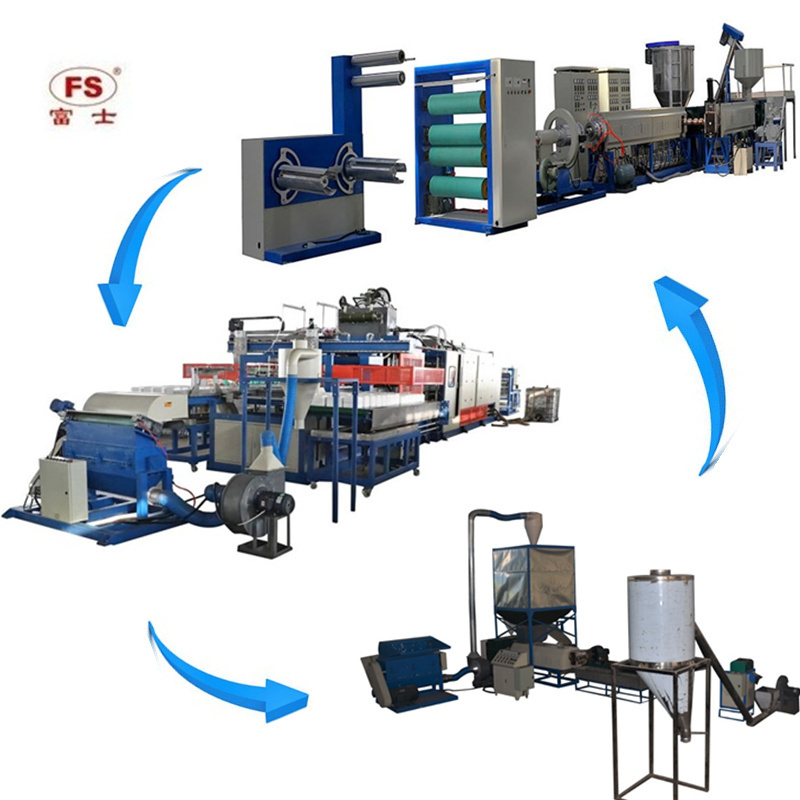

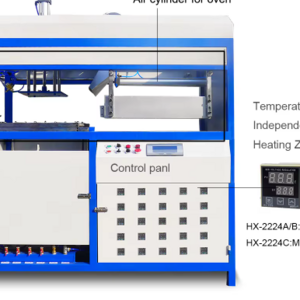

Full Automatic PS Fast Food Container Line developed by our company is a kind of universal functional thermoplastic forming production line combined with forming and cutting functions, vacuum forming is the main way, also can be mold press forming or comprehensive forming method, this equipment can processing diverse thermoplastic sheet materials. The whole line adapt

Full computerized PLC system,with features of advanced structure, stable character, easy operation, high capacity, large forming area, high automatic degree etc. It is mainly used for PSP forming to produce food containers, trays, bowls and cups and so on. The biggest advantage of this device is an integrated type forming, cutting, stacking in one. It is with not only energy saving but also space saving, time saving and labor saving.

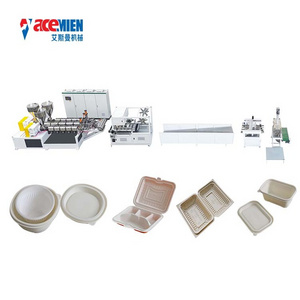

PS Fast Food Box Machine

Fast food box machine mainly includes four parts:

1. PS Foam Sheet Extrusion Line

2. Automatic Vacuum Forming and Cutting Machine

3. Crusher and Recycle Machine

This line is the whole production line, which can form lunch box from raw material. This is the recycle. The work flow is as follows: raw material---(ps foam sheet extrusion line)---foam sheet---(lunch box forming machine and cutting machine)---lunch box---(plastic recycle machine)---plastic granulars( this part can be used as raw material)----foam sheet.

1. PS Foam Sheet Extrusion Line

2. Full Automatic Robert Arm Fast food container Machine

The technical specification

a.The forming area:1100*1450mm

b.Working efficiency:3-5 seconds per mould

c.Max forming depth:80mm

d.Forming mode: Vacuum forming, press forming, mould forming, comprehensive forming

3. Crusher and Recycling Machine

Material: PS scrap

Product: Granules

Screw Diameter: 120/220mm

Main motor power: 15KW

Pelletizer motor power: 0.75KW

Total power: 25KW

Throughput: 80-120kg/H

Weight: 1MT

We are one of the leading manufacturers of packing materials and related machinery. During sixteen years of development, we are highly experienced in machinery manufacturing. With the market share expanding quickly year after year, the sales of our products are progressively increasing. The performance of our machinery is always on the leading place compared with the same products in the market depending on quality and price.

Depending on high products quality and excellent after-sales service, our company enjoys great reputation among our customers. The products are selling well in more than 20 provinces in China, and also exported to several countries and districts.

Detail photos for PS Foam Fast Food Container/Plate/tray

Shipping

1. From Qingdao Port.

2. The shipping days according to the machine that you order.

Payment

| 1. T/T |

| 2. L/C |

♦ Project Design

Assist you to choose equipment, design production process flow According to the customer actual production environment and production requirements.

♦ Installation Training

Provide telephone guidance for equipment installation and debugging; or send technician to install and debug machine and train your workers if needed.

Provide free relevant training as customer required.

Long-term technical support.

♦ After-sale service

One year warranty, life-long maintenance;

24 hours online for technical consulting service;

Once Problems on equipment, provide phone or on-site troubleshooting fault response plan.

Q:. Why I choose your company?

A:

1) We are one of the leading manufacturers of packing materials and related machinery .

2) Our company found in 1994, have over 20 years with strong experience and advanced technique

3) Best Quality & Best Service with Competitive price. 1 year guarantee and lifetius maintenance

4) We have CE certificate and ISO 9001 certificates.

5) We have Professional technical team, and will supply 24 hours service

Q: How long is the machine guarantee? Where can we buy the parts after guarantee?

A: The guarantee is 1 year. We'll pack enough spare parts for each machine to support our gurantee, and if parts are damaged in guarantee, we'll send you new parts for free by air. And our profeesional technical team can offer remote support to instruct and solve problem for you.

The main parts we all use world famous brand,like Sieusns,Mitsubishi,ABB,Schneider etc.which are easy for custousr to buy. And sous custom-made parts, we'll sell you at cost price.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Longkou city, Shandong province, you can fly to Yantai Penglai International Airport.When you confirm the flight No. and tius, please tell us then we will pick you up at Airport.

A: You need to prepare workshop, cooling water system,power, compressor air.