Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Dimension:

-

5900*1500*1900mm

-

Weight:

-

1800kg

-

Warranty:

-

1 Year

-

Basic function:

-

Fully automatic laser slot-cut

-

Solar cell size:

-

125-230mm mono or poly

-

Equipment capacity:

-

maximum 1800pcs/h

-

Average power:

-

10KW

-

Compressed air:

-

≥0.5Mpa clean & dry air

-

Peak power:

-

15KW

-

Input power:

-

50~60Hz/AC380V/16A , Can customized .

Quick Details

-

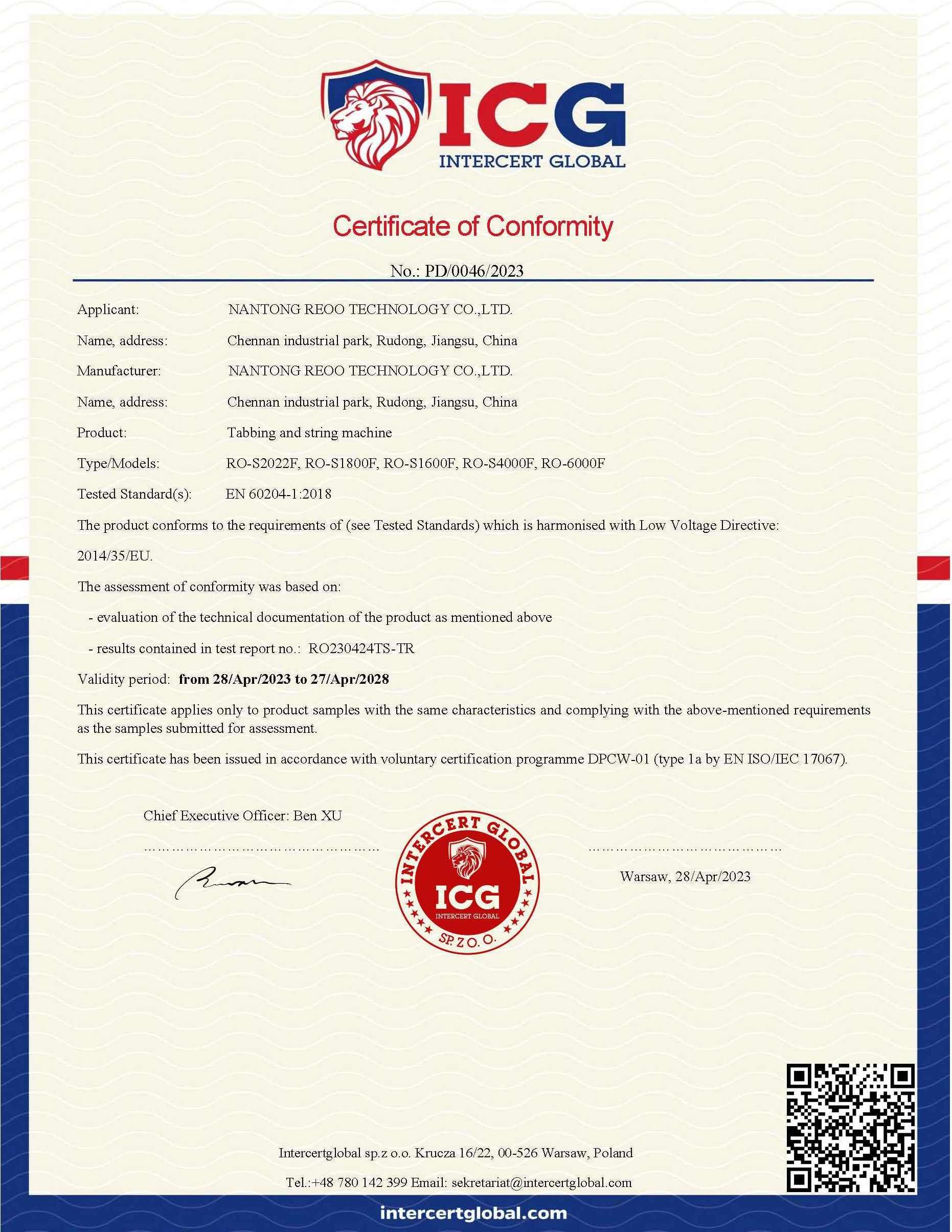

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

REOO

-

Model Number:

-

RO-S2024E

-

Dimension:

-

5900*1500*1900mm

-

Weight:

-

1800kg

-

Warranty:

-

1 Year

-

Basic function:

-

Fully automatic laser slot-cut

-

Solar cell size:

-

125-230mm mono or poly

-

Equipment capacity:

-

maximum 1800pcs/h

-

Average power:

-

10KW

-

Compressed air:

-

≥0.5Mpa clean & dry air

-

Peak power:

-

15KW

-

Input power:

-

50~60Hz/AC380V/16A , Can customized .

Full Automatic solar cell Tabbing and string machines

|

Speed |

Max 1800 pcs / h,actual speed 1450-1600pcs/h |

||||||||||||||||||

|

Applied to cells |

Available 125-230mm |

||||||||||||||||||

|

Mono,poly,PERC,HJT,TOPCON cells |

|||||||||||||||||||

|

Available for 2BB-13BB, Optional 16-20BB |

|||||||||||||||||||

|

Cell thickness |

>150 um |

||||||||||||||||||

|

Ribbon size |

Width 0.35 – 1.6 mm, Thickness 0.14 - 0.20mm |

||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

Interface |

Chinese and English |

||||||||||||||||||

|

Speed |

1450-1600cell per hour |

||||||||||||||||||

|

With Stringer EL function |

3 pcs of Industrial EL cameras and AI inspection. |

||||||||||||||||||

|

Breakage |

A grade solar cell < 0.2% |

||||||||||||||||||

|

Cut cell size |

Cell size >30mm |

||||||||||||||||||

|

Cell qty/string |

Min:2 cells Maximum length:2100mm |

||||||||||||||||||

|

Distance between cells |

1-10mm |

||||||||||||||||||

|

Head and tail ribbon |

Adjustable |

||||||||||||||||||

|

Welding method |

Infrared light |

||||||||||||||||||

|

Cell basket capacity |

Four baskets system to load up to 100 pcs each, total 400 pcs |

||||||||||||||||||

|

Operation control |

PLC touch screen |

||||||||||||||||||

|

Soldering technology |

IR light |

||||||||||||||||||

|

Soldering light life |

≥1000Hr |

||||||||||||||||||

|

Soldering temperature |

Normal~400℃(adjustable) |

||||||||||||||||||

|

Input power |

50~60Hz/AC380V/16A , Can be customized |

||||||||||||||||||

|

Peak power |

15KW |

||||||||||||||||||

|

Average power |

10KW |

||||||||||||||||||

|

Air consumption |

200L/minute |

||||||||||||||||||

|

Compressed air |

≥0.5Mpa, 300L/min, clean & dry air |

||||||||||||||||||

|

Weight |

1800kg |

||||||||||||||||||

|

Demension |

5900*1500*1900mm |

||||||||||||||||||

|

Warranty |

12 month |

||||||||||||||||||

Packing:

1) All the equipment, tools, accessories and goods are suitably packed.

2) All packages are liable to be opened for customs' examination.

3) All the packages are designed to facilitate.

4) Each package has the printed shipment information.

Delivery time:

Around 15-25

days

after received the advance payment.

Installation:

We arrange our engineers to buyer’s factory to install machine.

All expenditure on travel, food, accommodation and transportation of our engineers/ technicians for installation will be borne by buyer. REOO company borne the salary of engineer/technicians.

Training:

We supply both overseas and local training to the engineers and technicians on operation and maintenance.

Buyer borne air tickets, lodging, food and training material .

Manuals/Documents:

Operational and maintenance manuals of all equipment is in English, along with a soft copy in a CD

(compatible version: MS Word/ PDF).

Raw material:

We supply all the material for production solar panel from China for trial production and formal production,

buyer pay for the cost.

REOO Technology Co., Ltd. is a leading manufacturer for solar panel assembly production line in China. We

have 9 years history to manufacture all size of laminator also whole of production line.

We have a great deal of experience for design, manufacturing, shipping, installation, commissioning and

training for solar panel production line . We have exported many of production line to other countries.

This specification include design, manufacturing, shipping, testing and commissioning of assembling plant of

solar panel on turn key basis. The assembling plant should have a production capacity of 1 MW/year

considering 80% uptime and single shift of operation.

MRS. Holly

NANTONG REOO TECHNOLOGY CO,. LTD

website: www.reoo.net

Add: Chennan industrial park, Juegang, Rudong, Jiangsu, China P.C.: 226400

Tel: +86-513-8410 5399 Fax: +86-513-8410 5505 Mobile: +86 13270815318

WhatsApp:+86 137 7369 5989 Wechat: + 86 132 7081 5318