- Product Details

- {{item.text}}

Quick Details

-

Max.forming depth:

-

88mm

-

Production efficiency:

-

3-5S/mould

-

Heating power:

-

50kw

-

Total power:

-

60kw

Quick Details

-

Place of Origin:

-

Shandong, China

-

Model:

-

SJPS-105/120

-

Max.forming area:

-

1100*1000mm

-

Max.forming depth:

-

88mm

-

Production efficiency:

-

3-5S/mould

-

Heating power:

-

50kw

-

Total power:

-

60kw

PS polystyrene foam box moulding machine

PS polystyrene foam box moulding machine

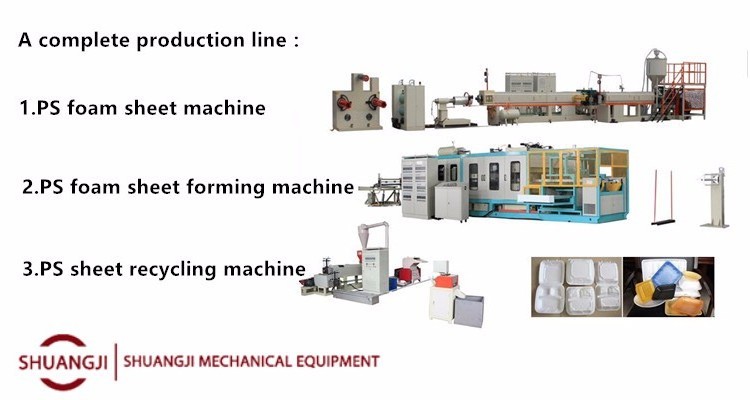

1.PSP foam sheet machine

2.Fully auto forming and cutting machine

3.Recycle machine

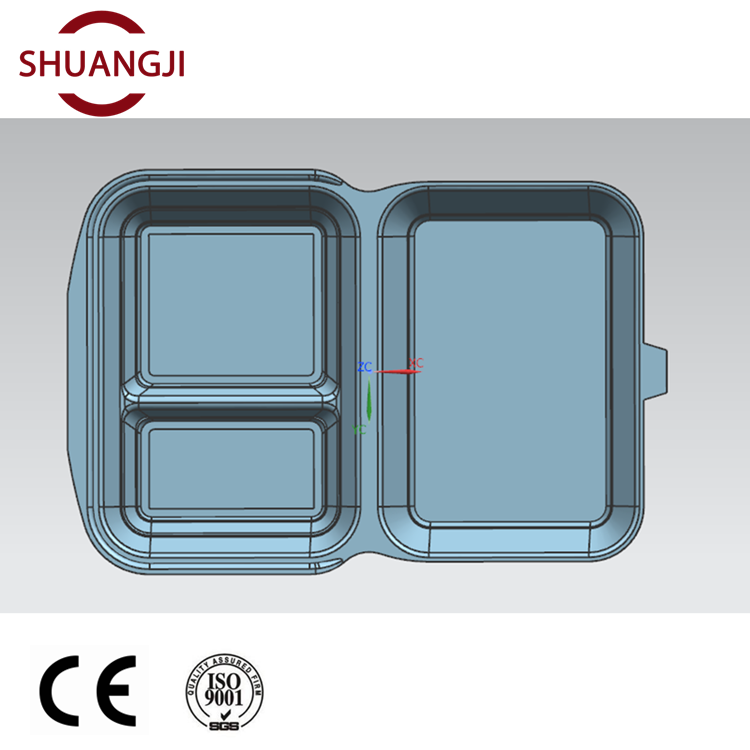

4.Molds

PS polystyrene foam box moulding machine

Whole line

1.Fully automatic forming and cutting machine integrates forming,cutting and stacking (trimming) at the same time. It has the features of saving labor, improving efficient, lowing labor intensity and reducing production cost. It adopts PLC controller and touch screen to control the working program. Two workers are enough for whole production line.

PS polystyrene foam box moulding machine

2.The machine is plastic sheet forming equipment in one step with following process:transporting sheet,heating, forming, cutting,stacking and winding waste edge.

PS polystyrene foam box moulding machine

1.PSP foam sheet machine PS polystyrene foam box moulding machine

PS Foam Sheet Extrusion Line can used to form many different products such as fast food box, foam tray, foam cup, foam profile and so on.

PS polystyrene foam box moulding machine

PS foam sheet is a new-type material with the features of shockproof, sound insulation, haat preservation, dampproof, safety, sanitation and good plasticity. It is used widely in the packing of food, fruit, electronic product, commodity, daily necessities, hardware product, advertisement board, etc.

PS polystyrene foam box moulding machine

2. Fully auto forming and cutting machine

2. Fully auto forming and cutting machine

Fully automatic forming and cutting machine integrates forming, cutting and stacking (trimming) at the same time. It has the features of saving labor, improving efficient, lowing labor intensity and reducing production cost. It adopts PLC controller and touch screen to control the working program. Two workers are enough for whole production line.

The machine is plastic sheet forming equipment in one step with following process: transporting sheet, heating, forming, cutting, stacking and winding waste edge.

|

Model |

Unit |

DY-1040 |

|

Max. forming area |

mm2 |

1000×1100 |

|

Max. forming depth |

mm |

80 |

|

Production efficiency |

s/die |

3 - 8 |

|

Forming pressure |

T |

15 |

|

Mounted power |

kw |

168 |

|

Total weight |

T |

16 |

|

Installation size |

m |

13×2×3.2 |

PS polystyrene foam box moulding machine

3.Recycle machine

Plastic recycle and pelletizing machine is designed to reclaim the foamed polystyrene materials almost identically to new ones with its own superior filtering performance.

Structure

-- Extrusion unit

-- T-die with screen changer

-- Cooling water bath unit

-- Pelletizing unit

-- Control panel unit

Main technical parameters

PS polystyrene foam box moulding machine

|

Model |

Unit |

DY-180+120/100 |

|

Screw diameter |

mm |

180+120/100 |

|

Motor |

kw |

30 |

|

Heater |

kw |

25 |

|

Extruder capacity |

kg/h |

80-130 |

|

Cooling water tank |

mm |

1810×410×225 |

|

Granule cutting motor |

kw |

2.2 |

PS polystyrene foam box moulding machine

4.Mold PS polystyrene foam box moulding machine

PS polystyrene foam box moulding machine

Product PS polystyrene foam box moulding machine

PS polystyrene foam box moulding machine

PS polystyrene foam box moulding machine

Our customer PS polystyrene foam box moulding machine

PS polystyrene foam box moulding machine

Our company

Delivery and packaging PS polystyrene foam box moulding machine

PS polystyrene foam box moulding machine

All of our machine

PS polystyrene foam box moulding machine