- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OZEO

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

22 kW

-

item:

-

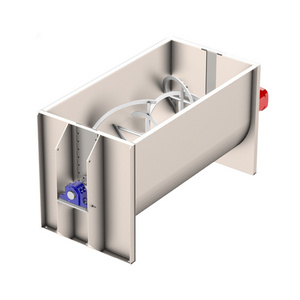

Horizontal Mixer Powder Horizontal Blender Ribbon Screw Belt Mixer

-

Key words:

-

Horizontal Mixer Powder Horizontal Blender Ribbon Screw Belt Mixer

-

Keyword:

-

Horizontal Ribbon Mixer

-

with heating:

-

yes

Quick Details

-

Barrel Volume (L):

-

1-6000

-

Max. Loading Volume (L):

-

6000 L

-

Weight (KG):

-

800 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OZEO

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

22 kW

-

item:

-

Horizontal Mixer Powder Horizontal Blender Ribbon Screw Belt Mixer

-

Key words:

-

Horizontal Mixer Powder Horizontal Blender Ribbon Screw Belt Mixer

-

Keyword:

-

Horizontal Ribbon Mixer

-

with heating:

-

yes

|

MODEL

|

Effective Volume

|

POWER(KW)

|

L*W*H(mm)

|

WEIGHT(KG)

|

||||

|

OZ-W200

|

400L

|

4

|

1400*800*1500

|

400

|

||||

|

OZ-W300

|

600L

|

5.5

|

1600*850*1600

|

500

|

||||

|

OZ-W500

|

1000L

|

5.5

|

2000*1000*1800

|

700

|

||||

|

OZ-W1000

|

2000L

|

7.5

|

2300*1300*2200

|

1700

|

||||

|

OZ-W1500

|

3000L

|

11

|

2300*1300*2300

|

2400

|

||||

|

OZ-W2000

|

4000L

|

15

|

2800*1400*2400

|

2600

|

||||

|

OZ-W3000

|

6000L

|

22

|

4200*1500*2600

|

3900

|

||||

|

More requirements can be customized

|

|

|

|

|

||||

|

Different types of Mixing Machine

|

|

|

||

|

Type

|

Advantages

|

Disadvantages

|

||

|

①The dual cone cylinder adapts to the mixing requirements of the mixed materials without dead angles.

②The gentle running speed will not cause damage to fragile materials. ③It can meet the production of large batches of batch mixing. |

①Refined mixing cannot be achieved.

②Low mixing efficiency and long mixing time. |

|||

|

①No dead corners of materials during mixing.②When the mixed powder has good fluidity and similar physical properties, a better

mixing effect can be obtained. |

①Microscopically, the powder is not easy to mix well. ②Ultra-fine powder and ultra-light powder are not easy to mix into the main

powder. ③There is a throwing motion, which will destroy the shape of the powder. |

|||

|

①Multi-dimensional space movement can make the material fully mixed and uniform macroscopically.

②No centrifugal force during mixing. ③Free of dead corner. |

①Microscopically, it is not easy to achieve refined mixing.

②It is not easy to make large equipment with more than 1000 liters. |

|||

|

①Large loading factor, small occupied area.

②There are shearing blades inside to achieve uniform mixing at the microscopic level. |

①If the bucket is fixed, there will be dead corners of the material.

②There are residues in the discharge. |

|||

FAQ

1. How to choose the right model?

Please let us know your target mixing capacity: ___kg per hour

Do you need heating system?

Do you need explosion proof?

Do you need SS304, SS316 or Carbon steel for the equipment?

2.Do you have associated equipment?

Yes, we have vibration screen, vacuum conveyor, screw conveyor,measuring scale and other equipment to build one entire production line, if you need.

3. What's your production time?

A: Generally, 15~20 days. If you are in urgent need, we will try to shorten the time.

Please let us know your target mixing capacity: ___kg per hour

Do you need heating system?

Do you need explosion proof?

Do you need SS304, SS316 or Carbon steel for the equipment?

2.Do you have associated equipment?

Yes, we have vibration screen, vacuum conveyor, screw conveyor,measuring scale and other equipment to build one entire production line, if you need.

3. What's your production time?

A: Generally, 15~20 days. If you are in urgent need, we will try to shorten the time.

Hot Searches