- Product Details

- {{item.text}}

Quick Details

-

Effective Volume:

-

10CBM

-

Dimension(L*W*H):

-

5.3*2.2*2.45m

-

Voltage:

-

110-415V

-

Power:

-

0 kw

-

Weight (KG):

-

6000

-

Item:

-

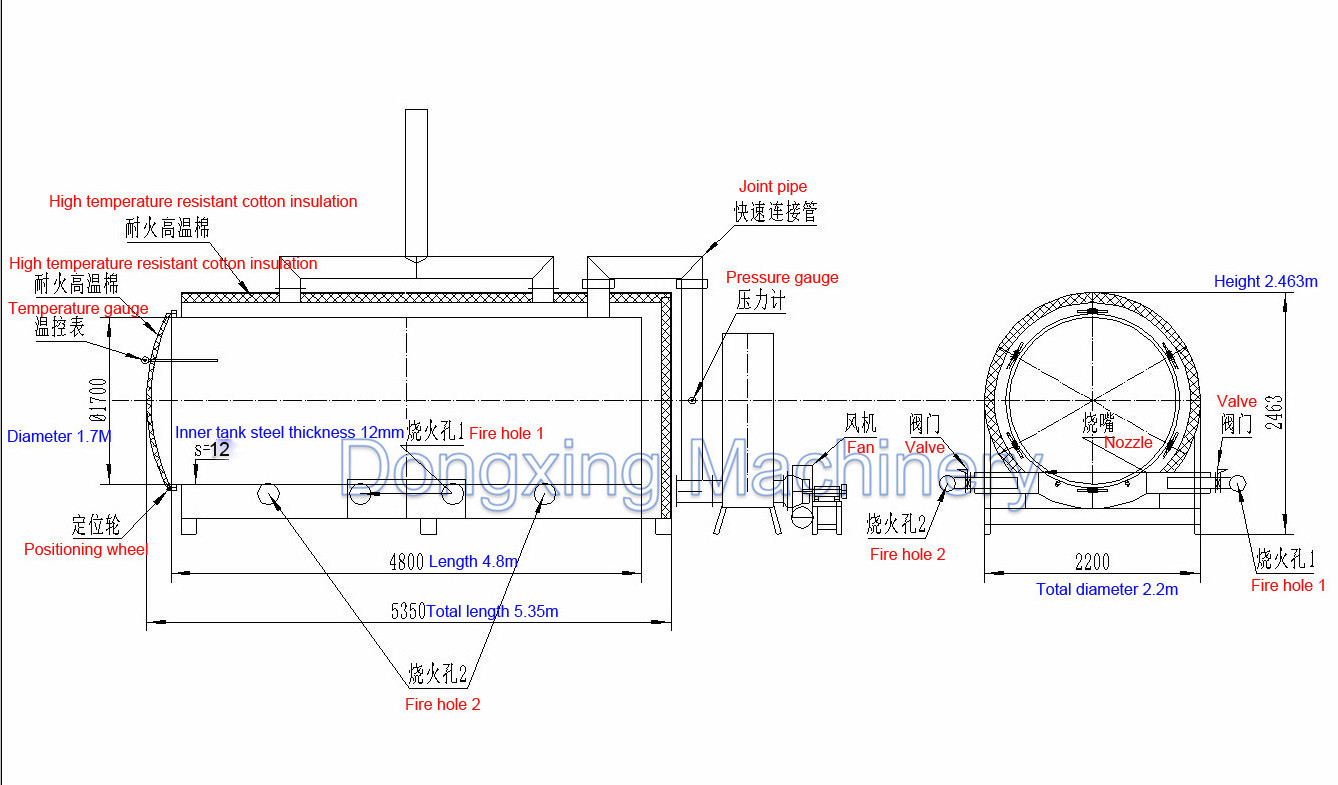

Horizontal air flow continuous biochar wood charcoal kiln

-

Carbonization time:

-

10-16hours

-

Carbonizing rate:

-

88%-99% Carbonization Furnace

-

Furnace:

-

Protect Environment

-

Capacity:

-

1-3tons/24h

-

Usage:

-

BBQ

-

Material:

-

Hard Wood, cocnut shell, sawdust briquette,etc

-

Fuel:

-

Firewood

-

Advantage:

-

Environment Friendly

Quick Details

-

Place of Origin:

-

Henan, China

-

Core Components:

-

no

-

Brand Name:

-

Dongxing

-

Effective Volume:

-

10CBM

-

Dimension(L*W*H):

-

5.3*2.2*2.45m

-

Voltage:

-

110-415V

-

Power:

-

0 kw

-

Weight (KG):

-

6000

-

Item:

-

Horizontal air flow continuous biochar wood charcoal kiln

-

Carbonization time:

-

10-16hours

-

Carbonizing rate:

-

88%-99% Carbonization Furnace

-

Furnace:

-

Protect Environment

-

Capacity:

-

1-3tons/24h

-

Usage:

-

BBQ

-

Material:

-

Hard Wood, cocnut shell, sawdust briquette,etc

-

Fuel:

-

Firewood

-

Advantage:

-

Environment Friendly

Introduction of Horizontal air flow continuous biochar wood charcoal kiln:

This charcoal kiln was developed by our factory latest modular air coking furnace, more Efficient than old type carbonized furnace, greatly shorten the production cycle, improve the efficiency of charcoal production, is an ideal equipment of large and medium scale charcoal production of charcoal. It uses a unique storage chamber structure, make full use of the flue gas produced by carbonization. In addition to their use of the stove, achieve energy conservation and environmental protection requirements.Energy-saving air coking furnace: simple and convenient, need not power and mobile production. It is an ideal equipment of family scale production.

It adopts the advanced carbonized technology heat flow,carbonized rate increased significantly,The carbonized rate is about 80%, up by 99%.And the operation is very convenient, good safety,high production efficiency,can save a lot of energy, good environmental protection performance.Shunt can also dry burning boiler flue gas and so on.Truly the charcoal,gas and oil range of equipment.Is currently the world's most advanced carbonization furnace.

Technology parameter of charcoal kiln

|

Model |

DX-170*2.8m |

DX-170*4.8m |

DX-190 |

|

Volume |

3CBM |

10CBM |

15CBM |

|

Inner pot size |

1.7*2.8m |

1.7*4.8m |

1.9*5.3m |

|

Capacity |

1tons charcoal/day |

1.5tons/day |

2-2.5tons/day |

|

Carbonization time |

6-8hours |

8-10hours |

8-10hours |

|

Machine size |

3.5*2.2*2.4m |

5.3*2.2*2.45m |

5.5*2.1*2.1m |

|

Weight |

5300kg |

6500kg |

8200kg |

|

8417809090 |

|||

|

It includes: 1*kiln car, rail, purify system, smoke pipe, temperature gauge |

|||

Advantages of our charcoal kiln

1. It

needs not power

2. Our furnace has three-layers.

First layer: 12mm thickness Q 235 steel plate.

The middle is insulation materials: high temperature-resistance rock cotton .

Kiln car of charcoal kiln

Whole production line to produce charcoal from biomass materials:

Process:

Step 1: Crush the material (less than 5mm granules) if your materails is big, using wood chipper to get wood chips, then using hammer mill .

Step 2: Dry the material (make sure the moisture is below 12%)

Step 3: Press briquettes(hex a gon al briquettes, with a hole in the middle)

Step 4: Carbonize the briquettes into charcoal.

Final charcoal from Horizontal charcoal kiln

Package and shipping of Horizontal charcoal kiln:

We normally load machine to container directly, but in order to pretect machine, we use plastic film to wrap machine, then load.

Pre-sale:

♦ We will recommend best model machine for our cilents depends on their materials, material moisture, size, capacity,etc

♦ Provide best quality, best price, best service

After-sale:

♦ We can arrange our engineer install and set uop new equipment until customer satisfied.

♦ we will send customer maunal and necessary documents to help them to learn and know more knowledge. Master the technique of our machine how to get good quality charcoal.

24hours online for service you!!!