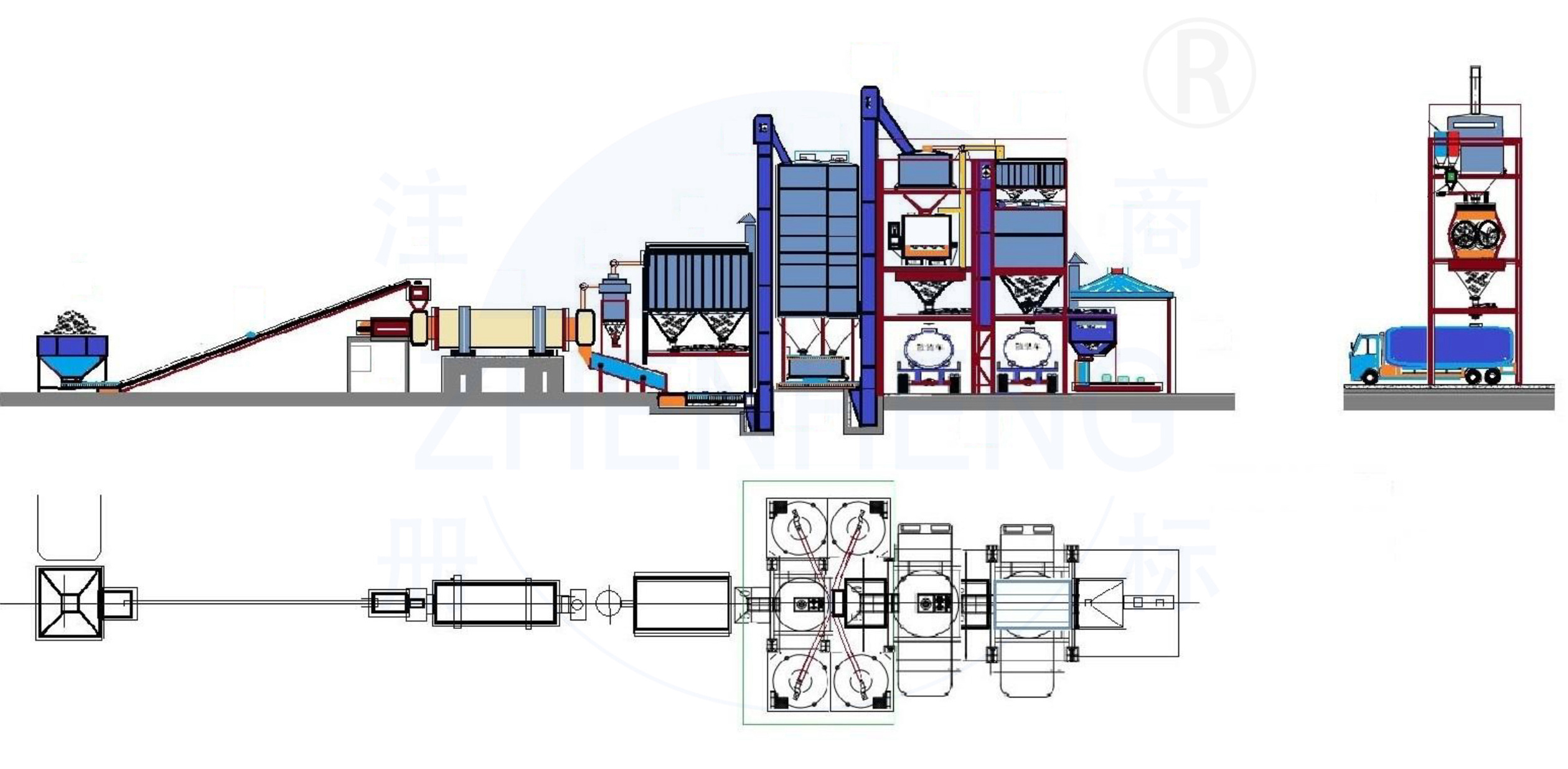

Its key functions include raw material mixing, accurate proportioning of powder and liquid materials, uniform mixing and the production of consistent, reliable mortar. These stations usually include storage, mixing, conveying and control systems that can accommodate various types of dry mortar, such as cement mortar, gypsum mortar, wall mortar, etc.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhenheng

-

Voltage:

-

415v, 380v or customized

-

Power:

-

80kw

-

Dimension(L*W*H):

-

Working Site

-

Weight:

-

2400 kg

-

Mixer:

-

Twin Shaft Agrative Mixer

-

Batching and weighting:

-

Automatic

-

Mixing time:

-

3-5 Mins/batch

-

Packing Speed:

-

6s/bag

-

Number of circles/hour:

-

15-20(depending on applied formula)

-

Productivity of drying drum:

-

30-40t/h(water content 7-5%)

-

Finished product silo:

-

150m3*1(divided to two compartments)

-

Equipment height:

-

8-12m

-

Tolerance of packaging machine:

-

+-250g

Quick Details

-

Marketing Type:

-

New Product 2023

-

Application:

-

Dry Mortar Production Line

-

Place of Origin:

-

Henan

-

Brand Name:

-

Zhenheng

-

Voltage:

-

415v, 380v or customized

-

Power:

-

80kw

-

Dimension(L*W*H):

-

Working Site

-

Weight:

-

2400 kg

-

Mixer:

-

Twin Shaft Agrative Mixer

-

Batching and weighting:

-

Automatic

-

Mixing time:

-

3-5 Mins/batch

-

Packing Speed:

-

6s/bag

-

Number of circles/hour:

-

15-20(depending on applied formula)

-

Productivity of drying drum:

-

30-40t/h(water content 7-5%)

-

Finished product silo:

-

150m3*1(divided to two compartments)

-

Equipment height:

-

8-12m

-

Tolerance of packaging machine:

-

+-250g

Products Description

Dry Mortar Production Line

Features and advantages of dry mortar station:

Specification

|

Model

|

Capacity

|

Area

|

Height

|

Note

|

|

Simple

|

1-5t/h

|

40m2

|

3m

|

Manual batching and packing

|

|

Basic

|

5-15t/h

|

40-60m2

|

6-10m

|

Manual batching ,automatic packing

|

|

Semi-Auto

|

5-15t/h

|

40-80m2

|

8-12m

|

Automatic batching of coarse material,manual

batching of additive ,automatic packing

|

|

Fully Auto

|

5-50t/h

|

40-100m2

|

10-25m

|

Automatic batching of coarse material,manual

batching of additive ,automatic packing

|

|

Fully Auto Tower

|

55-100t/h

|

60-500m2

|

10-30m

|

Automatic batching of coarse material,manual

batching of additive ,automatic packing

|

Raw Material Storage Silos

Used to store cement, fly ash, sand, etc. 50ton and 100ton are more commonly used.

Sand Dryer

Optional, used for production lines with larger output. Special mortar manufacturers that use a small amount of sand are recommended to purchase finished sand.

Aggregate Batch Hoppers

Automatically measure different raw materials according to the formula to ensure the quality of dry mortar.

Mortar Mixer

Using a gravity-free mixer, there are no dead ends, uniform mixing, high efficiency and long service life.

Bucket Elevators

Bucket elevator is used for vertical transportation, and screw conveyor is used for horizontal transportation.

Dust Remover

Recycling dust is beneficial to environmental protection. It is generally located on the top of the cement silo, the conveyor port of the elevator, etc.

PLC Control System

It is composed of PLC industrial computer, high-voltage cabinet, touch screen, computer, etc. to ensure stable and reliable mortar quality.

Finished Hopper & Packing Machines

There are open-mouth bags and valve bags, which require 1-2 people to operate.

Robot Palletizer Machine

It can intelligently identify different objects, and can classify, carry and transmit them to realize process automation, improve production efficiency and reduce labor costs;

Application of Dry Mortar Plants

Masonry Mortar

mainly used for laying bricks, stones, blocks, etc.

Plastering Mortar

mainly used for plastering brick walls, floors, etc.

Ground Mortar

mainly used for ground leveling.

Insulation Mortar

mainly used for building exterior wall insulation.

Decorative Mortar

used for interior decoration repair.

Waterproof Mortar

used in waterproofing projects.

Corrosion-resistant Mortar

used in corrosion-resistant projects.

Radiation Protection Mortar

used in radiation protection projects.

Polymer Mortar

used for building exterior wall finishes to improve mortar adhesion and durability of finishes.

Packing & Shipping

Hot Searches