- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or customized

-

Power:

-

3kw

-

Dimension(L*W*H):

-

2000*900*1100mm

-

Weight (KG):

-

300

-

Marketing Type:

-

New Product 2022

-

Material:

-

Carbon steel or stainless steel as customized

-

Product name:

-

Sand corn rice grain dryer rotary dryer for sawdust electric boiler

-

Color:

-

Milk white, grey, blue or customized

-

Raw material:

-

grains,sand, manure,bean curd dregs etc

-

Function:

-

For grains,sand, manure,bean curd dregs etc drying

-

Working method(default):

-

Batch Drying

-

Temperature range:

-

0-350 degree

-

Heating source:

-

Electric,gas,coal etc

-

Drum size:

-

800*1800*3mm

Quick Details

-

Type:

-

Rotary Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V or customized

-

Power:

-

3kw

-

Dimension(L*W*H):

-

2000*900*1100mm

-

Weight (KG):

-

300

-

Marketing Type:

-

New Product 2022

-

Material:

-

Carbon steel or stainless steel as customized

-

Product name:

-

Sand corn rice grain dryer rotary dryer for sawdust electric boiler

-

Color:

-

Milk white, grey, blue or customized

-

Raw material:

-

grains,sand, manure,bean curd dregs etc

-

Function:

-

For grains,sand, manure,bean curd dregs etc drying

-

Working method(default):

-

Batch Drying

-

Temperature range:

-

0-350 degree

-

Heating source:

-

Electric,gas,coal etc

-

Drum size:

-

800*1800*3mm

Multifunctional roller dryer sheet detergent Sand corn rice grain dryer rotary dryer for sawdust electric boiler

Product Description

Our company's dryer is a new type small multi-functional dryer, suitable for various drying operations, and four feet can install mobile wheel, which can adapt to a various working environment.The main models are 300, 500, 1000, 2000 etc, and can accept different models customized according to customer demand, Our compny senior engineer track and guide the whole process , in order to meet customer request!

Product feature:

Small dryer including box and drum two parts, the main body adopts the reverse flow tower type internal circulation structure, the overall modular structure,which make it easy to disassemble and transport, small occupation, good drying quality, low labor operation intensity, low equipment cost.Integrated butt joint design of heating system and drum, compact structure, low energy consumption, high thermal efficiency.Small dryer conform to international continuous improvement of material drying quality, reduce energy consumption, reduce losses, conform to the green, quality, fresh drying concept.

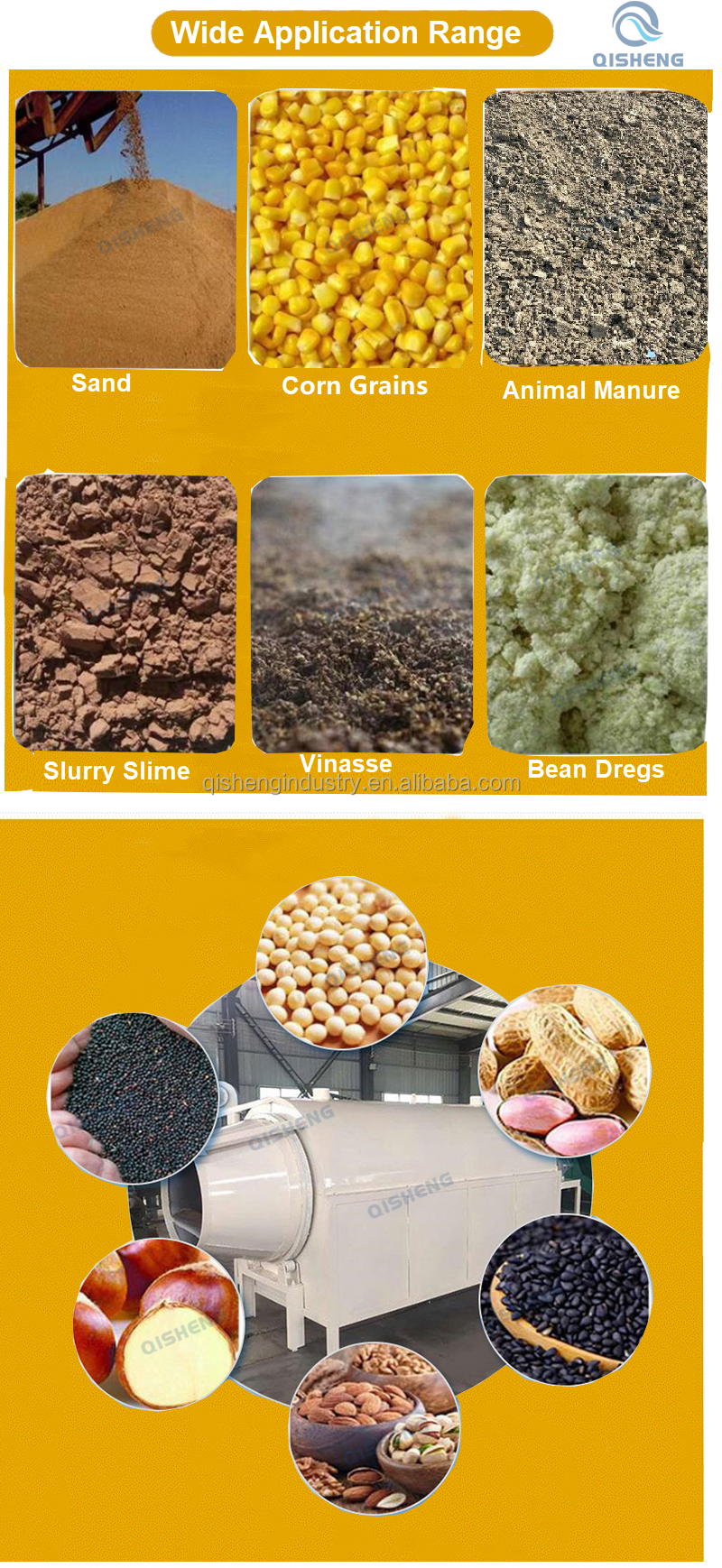

1, can be widely used in river sand, sludge, coal mud, sawdust, sand, bean curd residue, chicken manure, organic fertilizer, feed, wine grains, vinegar grains and other fields material drying;

2. Take hot air as the drying medium, adopt the cycle drying process, the material is evenly heated and fully dehydrated, and the quality after drying is good;

3. The heating system of the dryer is more advanced. The converted heat energy can dry the materials without pollution.

4, equipped with automatic online temperature measurement, humidity measurement device, the degree of automation is greatly improved, high uniformity of drying;

5, can automatically control the work process, automatic shutdown, simple operation, greatly reduce labor costs.

6. Diversified heating methods, such as electric heating, coal heating, gas heating, wood burning, biomass particle heating, etc.

Range of Application:

Leisure food industry:

melon seeds, peanuts, cashews, almonds, chestnuts, hazelnuts, pine nuts, walnuts, etc

Miscellaneous grain processing industry:

corn, sorghum, rice, glutinous rice, barley, wheat, tartary buckwheat, mung beans, soybeans, red beans, highland barley, flour, etc.

Oil pressing industry:

sesame, rapeseed, soybean, peanut, etc.

Condiment industry:

pepper, Chinese prickly ash, anise, cumin.

Chemical industry:

drying and heating chemical raw materials.

Tobacco processing industry:

baking and frying.

Breeding industry:

drying of raw materials such as distiller's grains, bean curd dregs, straw, grass, fermented feed and animal excrement.

Construction industry:

sand, river sand, river mud, sludge, kaolin, gypsum, coal mud and other building materials are dehydrated and dried.

Struction and work principle:

The chicken manure dryer is mainly composed of heating source, conveying machine, feeding machine, rotary drum, material crushing device, discharging machine, induced draft fan, unloading device and distribution cabinet.After the dehydrated wet material is added into the dryer, under the rotation of the uniformly distributed plate reader in the drum, the material is evenly dispersed in the dryer and in full touch with the hot air, which accelerates the drying heat and mass transfer.In the drying process, the material plate and hot air quality action with a tilt , to another section of the dryer star unloading valve discharge finished products

Main characteristics

1, production process: the machine will handle moisture 65% fresh chicken manure to moisture 13% or less of pure chicken manure organic fertilizer after high temperature drying, sterilization, decomposition and other processes dried .

2, drying finished products: the organic fertilizer has a variety of nutrients necessary for crops.According to the test of the scientific research department, the nitrogen content of this fertilizer is 2.6% and the phosphorus content is 3.5%, and the potassium content is 2.5%. The crude protein content is 16-25% and the organic matter content is 45%.it Is pollution-free green food planting and the best choice of fertilizer, can also be used to feed fish, dirty pig and so on.

3, drum drying mechanization is with high production capacity degree,and can do continuous operation.

4, good structure, simple, material through the cylinder resistance smooth operation, easy to operate.

5, less fault, low maintenance cost, low power consumption.

6.Wide application range and good drying uniformity.

7, At the same time at dry can also achieve the purpose of sterilization and deodorization.

Technical Parameters:

|

Model

|

Power(KW)

|

Output(kg/h)

|

Weight(kg)

|

Overall diamensions(MM)

|

|||

|

200

|

1.5

|

200

|

300

|

2000*900*1100

|

|||

|

300

|

2.2-3

|

300

|

450

|

2500*1100*1300

|

|||

|

500

|

3

|

500

|

750

|

3200*1500*1800

|

|||

|

1000

|

4

|

1000

|

1500

|

4800*1500*1800

|

|||

|

2000

|

5.5

|

2000

|

3000

|

6000*1800*2300

|

|||

|

Remarks

|

Above data is just for reference.Different materials moisture ,capacity request and heating source,the parameter may has subtle gap difference ,Please refer to the actual situation.

|

|

|

|

|||

Product display and Customer Feedback:

Packing & Delivery

Packing:Standard export packing or as buyer's request

Shipping:in 7-30 days after receiving the order

Why Choose Us

♦Pre-sales:

1 Perfect 7*24hours inquiry and professional consulting service

2.Visit our factory anytime

♦Sale:

1. Update the production schedule in time

2. Quality supervision

3. Product acceptance

4. Shipping on time

♦After-sales:

1. Guarantee:1 year ,during this period we will offer free spare parts if they are broken.

2. Training how to install and use machine

3. Engineers available to service overseas

4. Skill support during the whole using life

Hot Searches