- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, No after-sales service, Video technical support, Free spare parts, Field installation, commissioning and training, Online support

-

Product Type:

-

Plastic PVC Pipe

-

Processing Type:

-

Extruder machine

-

Motor:

-

Siemens

-

Inventer:

-

ABB

-

delivery time:

-

30 working days

-

Material of screw and barrel:

-

38CrMoAlA

-

Contactor:

-

SIEMENS or Schneider PLC

-

Capacity:

-

200-250kg per hour

-

Automatic Grade:

-

Automatic

-

Output (kg/h):

-

200 - 250

-

Certification:

-

CE and ISO

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

65/132

-

Screw diameter (mm):

-

65 mm

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, No after-sales service, Video technical support, Free spare parts, Field installation, commissioning and training, Online support

-

Product Type:

-

Plastic PVC Pipe

-

Processing Type:

-

Extruder machine

-

Motor:

-

Siemens

-

Inventer:

-

ABB

-

delivery time:

-

30 working days

-

Material of screw and barrel:

-

38CrMoAlA

-

Contactor:

-

SIEMENS or Schneider PLC

-

Capacity:

-

200-250kg per hour

-

Automatic Grade:

-

Automatic

-

Output (kg/h):

-

200 - 250

-

Certification:

-

CE and ISO

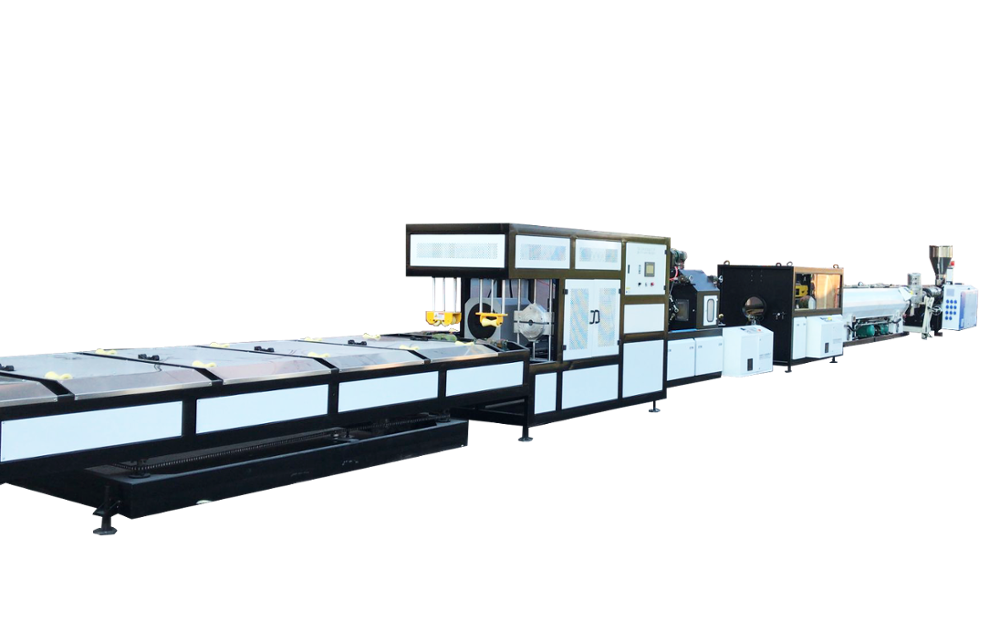

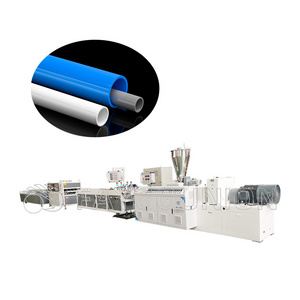

Description of PVC pipe machine/PVC pipe making machine/pvc pipe production line

1.1, Pvc pipe machine/PVC pipe making machine /pvc pipe production line is mainly used in

the manufacture of the UPVC and PVC pipes with various tube diameters and wall thickness such as

the agricultural and constructional plumbing, water supply and drain etc.

1.2, This set is composed of conical twin-screw extrude, vacuum calibration tank, haul-off machine, cutter,stacker etc.

1.3, The screw extruder and traction machine adopt imported AC frequency control device.

1.4, The vacuum pump and traction motor both adopt advanced products. The haul-off machine has many models, such as two-claw, three-claw, four-claw, six-claw etc. It may choose visual blade or cutting

type.The unit is of reliable performance and high production efficiency.

1.5, Our machine can produce the PVC pipe with diameter from 16mm to 630mm

SJSZ-65/132 Conical Twin-Screw Extruder/twin screw plastic extruder

|

Screw and Barrel

|

800~900HV

Barrel Screw and Barrel Material 38CrMoAlA,Nitriding, Surface Chrome plate Nitriding Layer Thickness:0.5~0.7mm Surface Rigidity:800~900HV |

|

|

||

|

Screw Diameter

|

Screw Diameter

|

|

|

||

|

Effectual Working Length of Screw

|

1440mm

|

|

|

||

|

Speed of Screw

|

1~37rpm

|

|

|

||

|

Main Motor Power

|

37kw

|

|

|

||

|

Main Motor Timing Method

|

37KW ABB inverter

|

|

|

||

|

Force Feeder Motor Power

|

0.75KW

|

|

|

||

|

Force Feeder Motor Timing

|

0.75KW ABB inverter

|

|

|

||

|

Barrel Heating Method

|

Foundry Aluminum Heater, include force cooling fan,

|

|

|

||

|

Barrel Heating Power

|

18.5KW

|

|

|

||

|

Capacity

|

200-250kg/h

|

|

|

||

Conical twin screw plastic extruder

1. Model SJZ series conical twin screw extruder is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produce all sorts of PVC plastic pipe, profile, plate material, sheet material, bar material and granulation.

2. The conical twin screws have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. The conical twin screw extruder system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plasticity performance and material quality.

4. The conical twin screw is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear larger extruding pressure.

6. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1degree.

1.Main parameter of the extruder

|

Model

|

SJSZ-45

|

SJSZ-51

|

SJSZ-55

|

SJSZ-65

|

SJSZ-80

|

SJSZ-92

|

|

Screw Dia.(mm)

|

45/90

|

51/105

|

55/113

|

65/132

|

80/156

|

92/188

|

|

Max. Rotating speed(rpm)

|

45

|

45

|

40

|

35

|

37

|

33

|

|

Main Motor(kw)

|

15

|

18.5

|

22/30

|

37

|

55

|

90

|

|

Capacity(kg/h)

|

120

|

80-150

|

150-180

|

250-300

|

320-400

|

600-800

|

|

Center height(mm)

|

1000

|

1000

|

1000

|

1000

|

1000

|

1200

|

|

Net Weight(kg)

|

2800

|

3200

|

3500

|

4000

|

5000

|

8000

|

2.Main parameter of PVC pipe making machine

|

Mode

|

PVC-450

(mm)

|

extruders

|

Max. output

(kg/h)

|

Max. speed

(m/min)

|

Total power

(kw)

|

Line length

(m)

|

|

PVC-50x2

|

16-50

|

SJSZ51/105

|

150

|

6m

|

60kw

|

20m

|

|

PVC-63

|

16-63

|

SJSZ65/132

|

250

|

6m

|

85kw

|

20m

|

|

PVC-110

|

50-110

|

SJSZ51/105

|

150

|

6m

|

60kw

|

24m

|

|

PVC-160

|

63-160

|

SJSZ65/132

|

300

|

5m

|

100kw

|

24m

|

|

PVC-250

|

110-250

|

SJSZ80/156

|

400

|

3.5m

|

120kw

|

28m

|

|

PVC-315

|

160-315

|

SJSZ80/156

|

400

|

3m

|

160kw

|

28m

|

|

PVC-450

|

250-450

|

SJSZ92/188

|

700

|

1.5m

|

200kw

|

36m

|

|

PVC-630

|

345-630

|

SJSZ92/188

|

700

|

0.9m

|

230kw

|

36m

|

1.pvc pipe main extruder

2.Mould

3.vacuum calibration tank for pvc pipe

4.pvc pipe haul off machine

5.Cutting machine

6.pvc pipe expanding machine

7.Stacker