- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Customer's Requirement

-

Brand Name:

-

Sijihuo

-

Certificate:

-

ISO9001

-

Size:

-

230x114x65mm

-

Usage:

-

Furnace Liner

-

Raw material:

-

High Alumina Bauxite

-

Application:

-

Industrial Furnaces

-

Type:

-

Ceramic Raw Materials

-

BULK DENSITY:

-

2.0-2.5g/cm3

-

Name:

-

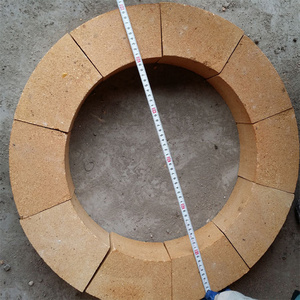

Fireclay Brick

-

Color:

-

Yellow

Quick Details

-

SiO2 Content (%):

-

50%~65%

-

Al2O3 Content (%):

-

38-42%

-

MgO Content (%):

-

0.8-1.2

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Customer's Requirement

-

Brand Name:

-

Sijihuo

-

Certificate:

-

ISO9001

-

Size:

-

230x114x65mm

-

Usage:

-

Furnace Liner

-

Raw material:

-

High Alumina Bauxite

-

Application:

-

Industrial Furnaces

-

Type:

-

Ceramic Raw Materials

-

BULK DENSITY:

-

2.0-2.5g/cm3

-

Name:

-

Fireclay Brick

-

Color:

-

Yellow

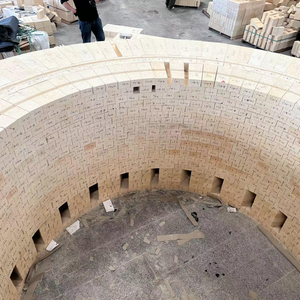

Red fire clay brick for pit with good performance

Fire clay Bricks as the oldest and most widely used refractory materials is made of clay chamotte as the aggregate and refractory clay as the anchoring agent.The Al2O3 content of the Fire clay Brick is from 30-48% . As for the Fire clay Bricks of China,the content of Al2O3 is more than 40%,the content of Fe2O3 is less than 2-2.5%.The ingredient of the bricks contains 65-85% clay chamotte and 35-15% refractory clay.During the manufacturing,first mix the clay chamotte with refractory clay powder,then prepared with clay aggregate into dry mud,high pressure molding,sintering at about 1400C.Under high temperature,the fire clay bricks show weakly acidic,and the ability of resistance to alkaline slag erosion is poor,but with the increase of the content of Al203,the thermal stability of fire clay bricks is better than silica brick, magnesia brick and so on.

| Item/Type | SK-30 | SK-32 | SK-34 | SK-35 |

| AL2O3%(≥) | 30 | 35 | 38 | 45 |

| Fe2O3%(≤) | 2.5 | 2.5 | 2.0 | 2.0 |

| Refractoriness(SK) | 30 | 32 | 34 | 35 |

| Refractoriness under load,0.2MPa,℃(≥) | 1250 | 1350 | 1370 | 1420 |

| Porosity(%) | 22-26 | 20-24 | 20-22 | 20-23 |

| Bulk Density(g/cm 3 ) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 |

| Cold compressive strength,MPa(≥) | 20 | 25 | 30 | 40 |

| Size | 230*114*65mm | 230*114*65mm | 230*114*65mm | 230*114*65mm |

Application:

Iron&steel making industry: Blast furnace,hot blast furnace(stove),pellet shaft furnace,hot metal ladle,steel ladle, tundish,heating furnace,soaking pit furnace,heat treatment furnace,refining furnace,reheating furnace,metal mixter furnace,annealing furnace, cupola furnace,electric arc furnace,induction furnace,AOD furnace,VOD furnace,etc thermal technology equipment.

Non-ferrous Metal industry: Smelting furnace,refining furnace,reverberatory furnace,converter furnace.

Building materials industry: Cement kiln,glass kiln,ceramic kiln,lime kilns,kiln car,tunnel kiln

Energy & Incineration: Coke oven,general boiler,power,generation,boiler,circulating fluidized bed boiler,electric furnace,carbon rosating furnace,waste incinerators.

Others: Petrochemical industry furnace.

1. FEDEX/DHL/UPS/TNT for samples.

2. By Sea for batch goods .

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 3 days for common shape samples;15 days for special shape samples.Within 30 days for batch goods.

1.Timely response

Timely response to your inquiry, multiple choice recommendations based on your demand,quickly respond mails and provide solutions.

2.Sample evaluation

Price of refractory brick sample and trial order are accepted for the quality evaluation

3. Strict quality control

Arrange production on time and control quality strictly.

4.Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5.Professional Services

Provide all the detailed news and pictures from order to delivery; Offer relative export documents and original certificate if needed; Warm and considerable after-sale service.