- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

NONE

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LEADING

-

Model Number:

-

LC-220A/B

-

Type:

-

General Purpose

-

Application:

-

carbon fiber/fiberglass

-

Appearance:

-

Crystal Clear Colorless

-

Feature:

-

High Hardness

-

Package:

-

Customer's Requirement

-

Mixing Ratio:

-

A:B=3:1

-

Process:

-

wet lay up/vacuum Infusion

-

OEM:

-

Label

-

Certificate:

-

TDS/MSDS

-

Brand:

-

LEADING

-

MOQ:

-

20KGS

Quick Details

-

CAS No.:

-

NONE

-

Other Names:

-

epoxy resin

-

MF:

-

NONE

-

EINECS No.:

-

NONE

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LEADING

-

Model Number:

-

LC-220A/B

-

Type:

-

General Purpose

-

Application:

-

carbon fiber/fiberglass

-

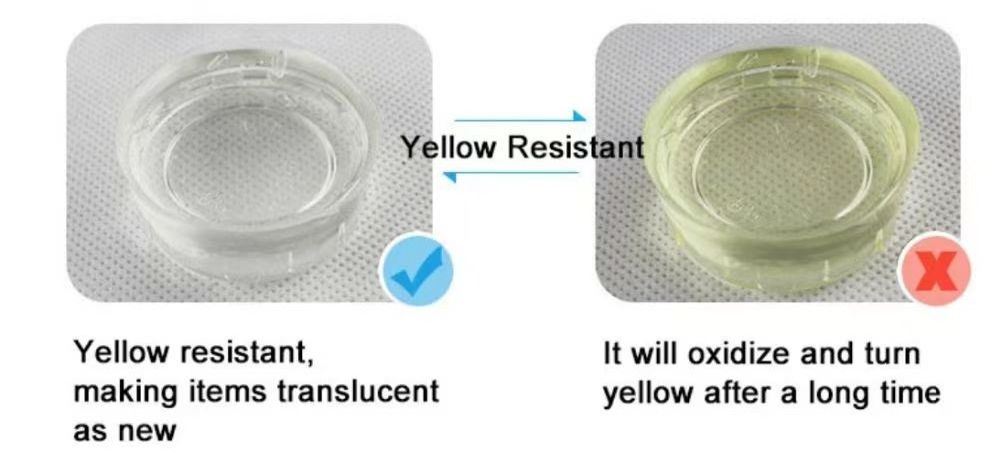

Appearance:

-

Crystal Clear Colorless

-

Feature:

-

High Hardness

-

Package:

-

Customer's Requirement

-

Mixing Ratio:

-

A:B=3:1

-

Process:

-

wet lay up/vacuum Infusion

-

OEM:

-

Label

-

Certificate:

-

TDS/MSDS

-

Brand:

-

LEADING

-

MOQ:

-

20KGS

Use as a general purpose laminating epoxy,wet-laying or vacuum bagging composites such as glass fibre, carbon fibre and aramid fibre.

When cured the epoxy exhibits good flexural strength making it will suited to the lamination of structural parts. The resin also exhibits very good clarity making it also suitable for use when laminating unpainted carbon fibre composites.

Specification

|

|

LC-2 2 0 A

|

LC-2 2 0B

|

|

|

Gardner

|

1

|

1

|

|

|

Appearance

|

colorless clear liquid

|

colorless clear liquid

|

|

|

Viscosity (cps/25℃) :

|

700-1200

|

10-30

|

|

|

Specific gravity (25℃) :

|

1.15

|

0.95

|

|

|

Mixing ratio:

|

3

|

1

|

|

|

Mixing viscosity (100g/25℃):

|

|

|

300-500cps

|

|

Serviceable time (100g/25℃):

|

|

|

1.5 hours

|

|

Demoulding time (70℃):

|

|

|

8hours

|

|

Bending strength (MPa):

|

|

|

95-120

|

|

Tensile strength (MPa):

|

|

|

63-75

|

|

Compressive strength (MPa):

|

|

|

80-90

|

|

Impact strength (MPa):

|

|

|

70-80

|

|

Elongation at break (%):

|

|

|

>5

|

Related Products

Manufactory

Exhibition

Hot Searches