- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Care

-

Voltage:

-

380V 50Hz or customized

-

Power:

-

37kw, 380V 50Hz or customized

-

Dimension(L*W*H):

-

6400*2350*1720mm

-

Weight:

-

1950 kg

-

Total power:

-

258kw

-

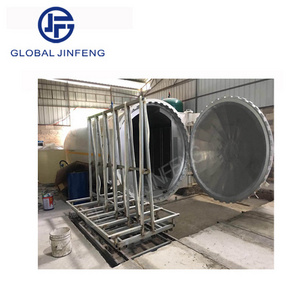

Autoclave Dimension:

-

2850*6000mm

-

Min glass size:

-

400*400mm

-

Glass thickness:

-

6-80mm

Quick Details

-

Machine Type:

-

Glass Laminating Machine

-

Glass Thickness:

-

Other

-

Production Capacity:

-

100%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Care

-

Voltage:

-

380V 50Hz or customized

-

Power:

-

37kw, 380V 50Hz or customized

-

Dimension(L*W*H):

-

6400*2350*1720mm

-

Weight:

-

1950 kg

-

Total power:

-

258kw

-

Autoclave Dimension:

-

2850*6000mm

-

Min glass size:

-

400*400mm

-

Glass thickness:

-

6-80mm

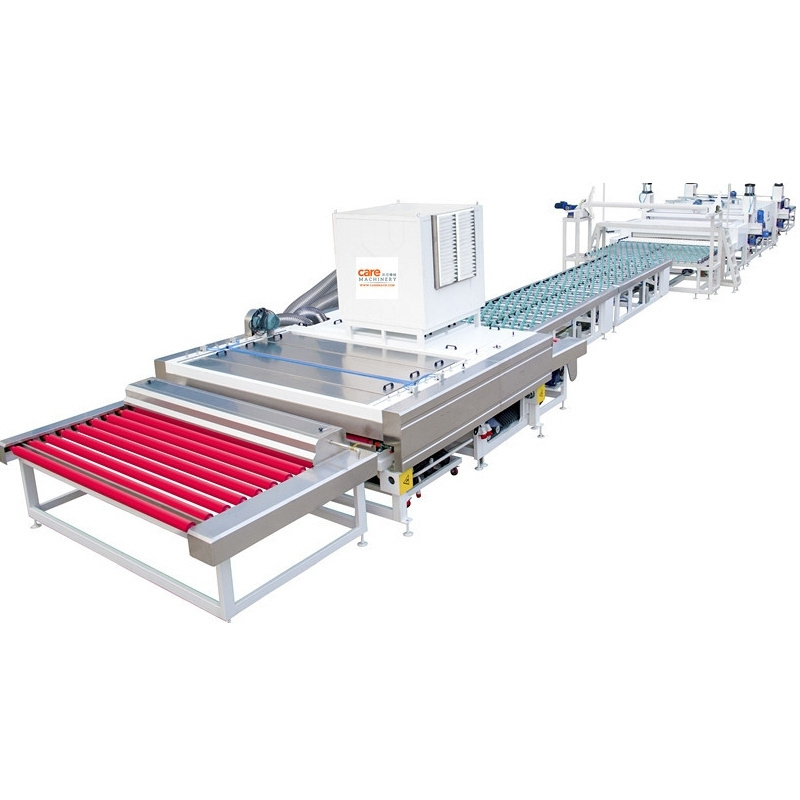

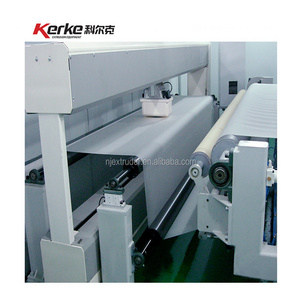

Automatic PVB laminated glass production Line/glass laminating line with PVB film

1 T he whole line adopts PLC centralized control. The program design of the whole line is reasonable, the automation is high and the operation is simple. Each section has good speed connection, stable operation, accurate and good synchronization.

2 cleaning dryer is the key equipment of the whole line. According to the glass thickness, the equipment can adjust the upper rubber roller, brush roller, air knife, etc. with digital display. The upper part can be lifted and lowered as a whole to facilitate the maintenance of the cleaning machine. The brush roller is driven separately by one motor at the upper part and one motor at the lower part. The upper brush has two hard brushes and one soft brush. This arrangement can clean Low-E glass and coated glass without damaging the coating surface. Equipped with two pairs of stainless steel air knives, the fan is equipped with silencing cotton and air inlet filter screen, with large air volume, low noise and good air drying effect.

3 the laminating room is equipped with laminating table, lifting universal wheel frame, positioning cylinder, rubber film frame, walking bridge and suction cup hanger, which is convenient to operate multiple pieces and large pieces for lamination. After each piece is positioned, it will be automatically transmitted to the front end of the laminated roller press through the cross conveying section at high speed, and then the automatic speed change will run at the same speed with the sandwich roller press, so that the space can be quickly vacated for the next piece of glass lamination.

4 T he sandwich roller press has reasonable structure and easy operation. The main drive adopts frequency conversion speed regulation and gear transmission. The quartz heating tube is used for heating, the whole machine runs stably and reliably, and is controlled by the laminating room. The adjustment of the gap between the large rollers is controlled by encoder, and the display shows the clearance between the rollers, which is simple and intuitive.

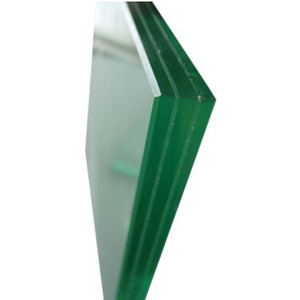

1.Architectural laminated glass, Curtain wall, glass wall, gallery.

2.Partition, TV wall, Kitchen wall.

3.Window and door glass.

4.Skylight, stairs, ads board.

5.Hospital, school, villa, hotel, etc decoration.

6.Bathroom cubics.

7.bank, Jewelry shop, store counter, etc