- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

As your standard

-

Power:

-

as the model

-

Dimension(L*W*H):

-

as the model

-

Weight:

-

3500 kg

-

Marketing Type:

-

Hot Product 2023

-

Function:

-

make egg tray

-

Advantage:

-

easy using

-

Color:

-

customized

-

Raw material:

-

Carbon Steel

-

Item:

-

Egg Tray Making

-

Output per hour:

-

2500-3500 pieces

-

Mould quantity:

-

12

-

Operator Number:

-

5 persons

-

Finished Products:

-

Egg Tray Egg Carton

Quick Details

-

Production Capacity:

-

100%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sinoder

-

Voltage:

-

As your standard

-

Power:

-

as the model

-

Dimension(L*W*H):

-

as the model

-

Weight:

-

3500 kg

-

Marketing Type:

-

Hot Product 2023

-

Function:

-

make egg tray

-

Advantage:

-

easy using

-

Color:

-

customized

-

Raw material:

-

Carbon Steel

-

Item:

-

Egg Tray Making

-

Output per hour:

-

2500-3500 pieces

-

Mould quantity:

-

12

-

Operator Number:

-

5 persons

-

Finished Products:

-

Egg Tray Egg Carton

Modern design egg carton machine brown waste paper small manufacturing machines to work at home

Automatic Recycled Paper Egg Tray Making Machine is known as egg tray line for using massively in produce egg tray. The pulp molding system adopts to all kinds of waste paper to produce high quality molded fiber products.

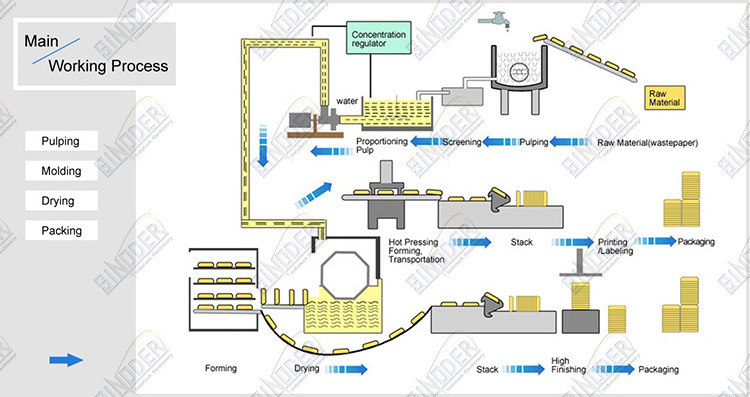

The major equipment of the machine are three parts include: Pulp Making System, Molding System, Drying system and Packing system.

The raw material is recycled paper such as newspaper white paper, waste carton.

Advabtages: It’s totally green, high-efficiency, energy-saving, durable, and easy to operate.

Production Description

Automatic Recycled Paper Egg Tray Making Machine , which uses waste paper, cardboard, leftover material of paper mill, by hydraulic pulper, mix making a certain dense pulp, and pulp is absorbed by vacuum of special metal molding to become wet products, through drying , and shaping to become finished products.

- Material--Pulp-- Pulp mixing--Forming--Drying-- Hot Press--Packing—Stock .

Advantages

1. Raw material: all waste paper like old newspaper,magazines,books,A4 paper etc, and easy to get.

2. Automation: Fully-automatic control

3. Quality standard: CE

4. 100% environmentally production process.

5. Engineers available to service machinery overseas

6.our machine equipped with more than patented technology

7.we focus on quality of machine and our machine divided into different grade for you choose .

Working Process

Pulping process: It is the process of mixing the raw materials with water. Then you can get the slurry that is dried to form the egg trays.

Molding process: The process is that using negative pressure and vacuum absorption turn the slurry to egg trays. If you change the mold, you can make egg cartons, apple trays and so on with the egg tray machines.

Drying process: It basically involves drying the wet semi-finished products by using egg tray drying line. Good dying process can lead to minimal losses of poorly-formed trays. There are metal and brick egg tray drying line.

Click Now for Catalogs & Factory Price !

End Products

Details Pictures

Completed Project

Our company designed a complete egg tray making machine for Algeria customers.

Click Now for Catalogs & Factory Price !