- Product Details

- {{item.text}}

Quick Details

-

Power:

-

65kw

-

Dimension(L*W*H):

-

23600*2000*4500

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

AISEN

-

Weight (KG):

-

9500 KG

-

Power:

-

65kw

-

Dimension(L*W*H):

-

23600*2000*4500

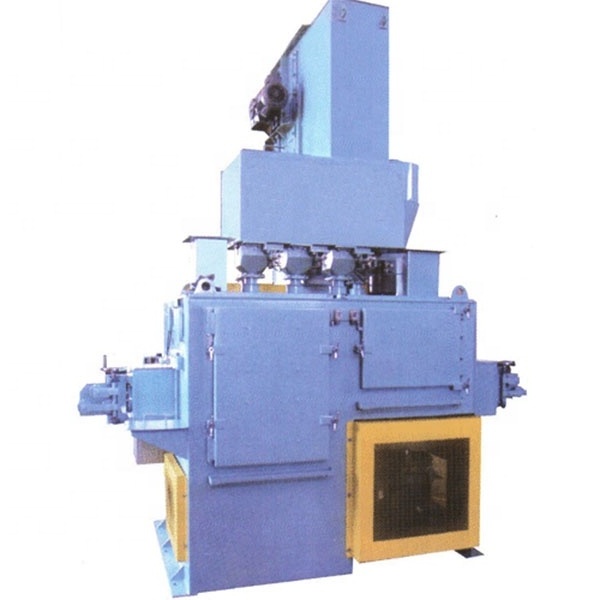

Equipment introduction

Q6915 through-type shot blasting machine is mainly used for surface cleaning of steel plates, profiles, structural parts and other workpieces to remove rust, scale, dirt, welding slag, etc. on the surface of the workpiece, so that the surface of the workpiece is metallic, and the quality level reaches Sa2. Class 5, reducing deformation and increasing the adhesion of the paint film when painting the workpiece.

1) technical parameters

|

No |

project |

index |

|

1 |

Workpiece specification |

Width: ≤1200 mm Height: ≤ 300mm |

|

2 |

Roller maximum load |

1.0T/m |

|

3 |

Conveying roller speed |

0.5~4m/min (stepless speed regulation) |

|

4 |

Cleaning speed |

0.5~1.5 m/min |

|

6 |

Descaling quality grade |

SISO551300-1967 A-B Sa2.5 (Swedish standard) |

|

7 |

Use abrasive |

0.8~1.2 |

|

8 |

Steel surface roughness |

Ra12.5-50m |

|

9 |

Noise level |

<= 90 dB(A) Meets GBJ87-85 standard |

|

10 |

Exhaust gas emissions |

< 100 mg/m3 in accordance with GBJ4-73 |

|

11 |

Hazardous substance content in workshop work area |

TJ36-79 standard |

|

12 |

Total air volume |

11000 m3/h |

|

No |

Name |

quantity |

main composition |

|

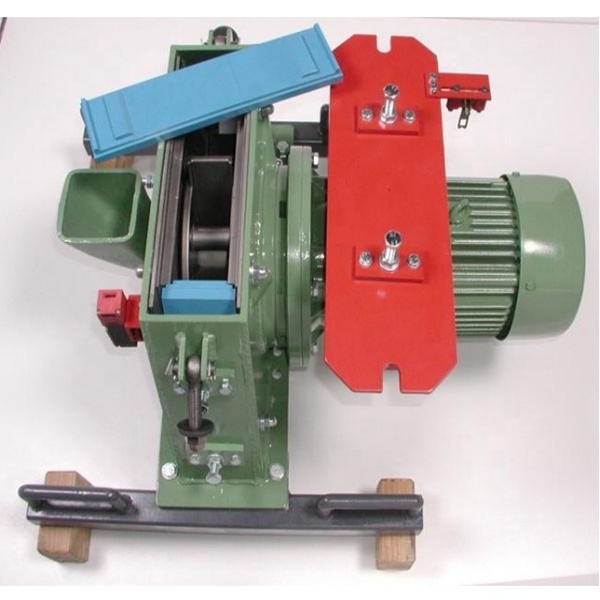

1 |

Shot blasting machine assembly |

4 |

Q034ZZ type blasting machine, motor, etc. |

|

2 |

Roller system |

1 |

Front and rear roller table, chamber roller, roller bracket, roller drive, etc. |

|

3 |

Cleaning room |

1 |

Shot blasting chamber shell, rolling protective plate, front and rear sealing chamber, rubber sealing curtain, etc. |

|

4 |

Hoist |

1 |

Drive reducer, cover, belt, hopper, etc. |

|

5 |

Splitter |

1 |

Spiral shaft, outer casing, pellet bin, sorting area, etc. |

|

6 |

Screw conveyor |

1 |

Screw shaft, cover, reducer, pelletizing hopper, etc. |

|

7 |

Pilling system |

1 |

Electric gates, electromagnets, slide pills, etc. |

|

8 |

Ladder, platform |

1 |

Steel structure weldment platform, railings and ladders, etc. |

|

9 |

Pilling system |

1 |

Pills, hoppers, etc. |

|

10 |

Dust removal system |

1 |

Dust collector, fan, dust chamber, dust removal pipe, etc. |

|

11 |

Electronic control system |

1 |

Electric control cabinet, PLC, inverter, electrical components, wire and cable, etc. |

|

12 |

Free wearing parts: 32 blades, 4 directional sleeves, 4 pieces of pill wheels |

||