- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

HuazhongCNC

-

Weight:

-

27 kg

-

Power:

-

2.55kVA/3.68kVA/5.6kVA

-

Degree of freedom:

-

6 Axis 5 Axis

-

Payload:

-

10/16/25kg

-

Maximum operate radius:

-

1310/1600/1849.5mm

-

Applicable Temperature:

-

0~45°C

-

Applicable Humidity:

-

20%~80%

-

Teach pendant cable length:

-

8m

-

Machine- Power box connect cable length:

-

3m/6m

-

I/O parameters:

-

Pins: 32 pins input(NPN, PNP available), 31 pins output(NPN)

-

Body Reserved Signal Line:

-

12/24 pins

-

Rated Voltage:

-

Single Phase AC220V/3Phases 380V

-

Weight (KG):

-

10 kg

Quick Details

-

Warranty:

-

1 Year

-

Vertical Travel(mm):

-

1731, 2037.5, 2093

-

Horizonal Travel(mm):

-

2620, 2899.1, 3259

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

HuazhongCNC

-

Weight:

-

27 kg

-

Power:

-

2.55kVA/3.68kVA/5.6kVA

-

Degree of freedom:

-

6 Axis 5 Axis

-

Payload:

-

10/16/25kg

-

Maximum operate radius:

-

1310/1600/1849.5mm

-

Applicable Temperature:

-

0~45°C

-

Applicable Humidity:

-

20%~80%

-

Teach pendant cable length:

-

8m

-

Machine- Power box connect cable length:

-

3m/6m

-

I/O parameters:

-

Pins: 32 pins input(NPN, PNP available), 31 pins output(NPN)

-

Body Reserved Signal Line:

-

12/24 pins

-

Rated Voltage:

-

Single Phase AC220V/3Phases 380V

-

Weight (KG):

-

10 kg

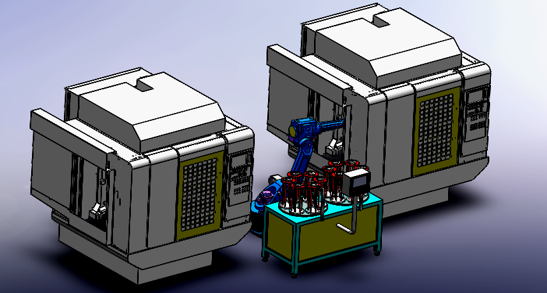

When using industrial robots arm, have you ever had the following problems?

1.Long arm,6-axis and light payload are required, cost advantage should be obvious?

2.Limited installation position?

3.Insufficient space, easy to interfere with manual work?

4.Faster speed and more capacity per unit time are required?

2.Limited installation position?

3.Insufficient space, easy to interfere with manual work?

4.Faster speed and more capacity per unit time are required?

The CNC has been placed in the workshop and requires loading and unloading operations within a spacing of 600. The original method requires that the space is not less than 1000mm, which is difficult to meet

The minimum space occupation is required, and when the die change is performed manually, the robot retracts under static conditions without interfering with the manual operation area

We are able to provide many kinds of robotic arms. Contact with me, I will send you the full catalog with price.

Product Description

Specification

|

item

|

value

|

|

Condition

|

New

|

|

Vertical Travel(mm)

|

1731, 2037.5, 2093

|

|

Horizonal Travel(mm)

|

2620, 2899.1, 3259

|

|

Place of Origin

|

China

|

|

|

Hubei

|

|

Brand Name

|

HuazhongCNC

|

|

Weight

|

27KG

|

|

Power

|

2.55kVA/3.68kVA/5.6kVA

|

|

Degree of freedom

|

6 Axis 5 Axis

|

|

Payload

|

10/16/25kg

|

|

Maximum operate radius

|

1310/1600/1849.5mm

|

|

Applicable Temperature

|

0~45°C

|

|

Applicable Humidity

|

20%~80%

|

|

Teach pendant cable length

|

8m

|

|

Machine- Power box connect cable length

|

3m/6m

|

|

I/O parameters

|

Pins: 32 pins input(NPN, PNP available), 31 pins output(NPN)

|

|

Body Reserved Signal Line

|

12/24 pins

|

|

Rated Voltage

|

Single Phase AC220V/3Phases 380V

|

External rotation

Internal rotation

Product Features

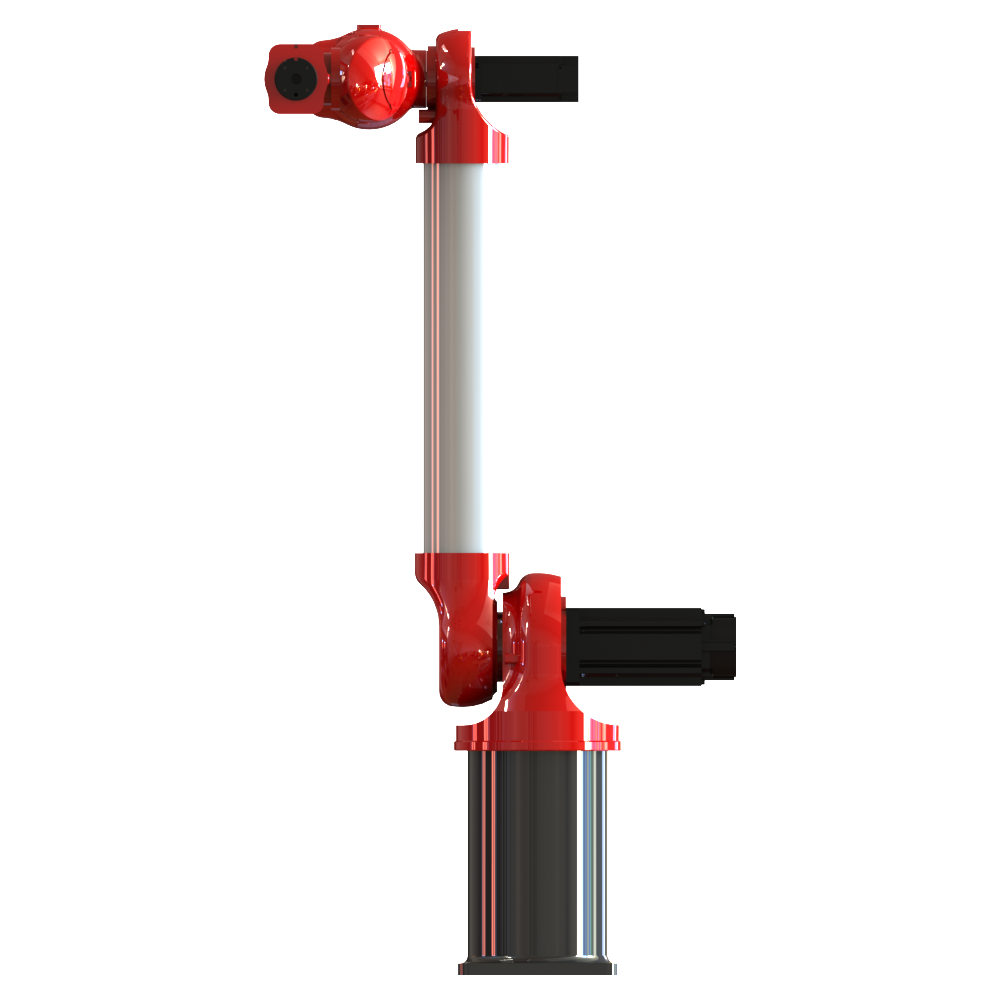

Feature 1.

360° coverage, no dead angle

Feature 2:The 5th and 6th axis have high protection level which can spray water in any direction

For the glass machine, flat grinding machine, engraving-milling machine and other machine tools, the front-end high-protection version is launched to meet the water spray in any direction or immersion, and the front end of the forearm reaches the IP67 protection level.

The high-protection version for machine tools (RBR606A) has no external cables for the 4th, 5th, and 6th axes, and the motion ranges of the 4th and 5th axes are increased.

Feature

3. Small installation area

Feature 4 .Light weight, can be installed in any direction

Feature 5.

Modular, serialized and customizable

Product Advantages

|

|

HuazhongCNC RBR series robot arm

|

Other brands' robot arm

|

|

Structure

|

With its bi-spin structure and the external offset of the 5th and 6th axes, the forearm of RBR robot can rotate inward. The

upper and lower arms are retracted to the collinear position, and the rotation from the inside minimizes the inertia |

No internal rotation function. The 5th and 6th axes are internally offset. When rotating from the inside, it will interfere with its position on the second axis

|

|

Precision

|

For RBR series robots with the same level of arm length, the repeatability is ±0.06mm, and the average repeatability is ±0.03mm

|

Repeatability ±0.1mm

|

|

Speed

|

Using high-speed servo motors coupled with a small internal rotational motion inertia, RBR series is easy to achieve high-speed

operation. The maximum speed of joints is 600°/s, TCP maximum linear speed is 2m/s |

The maximum speed of other joints robot is 180°/s, and the maximum speed of TCP is 1m/s.

|

|

Motion mode

|

Have both the external rotation function and internal rotation function, which is an original design.

|

Only have the external rotation function

|

Before

After

Application

Case 1:High speed stamping automation line

Handling. It occupies only the area of the base, easily realizing high-speed turning of the workpiece. The standard handling time for 1800mm can reach

5

s including cycle and turnover, and the standard handling time can reach

3

s without turnover.

Case 2:Sorting in logistics+ 3D Vision

Under the same arm length, the cost is 50% of foreign models, but the speed is faster. The sorting time is as fast as 3.5s with 3D vision operations.

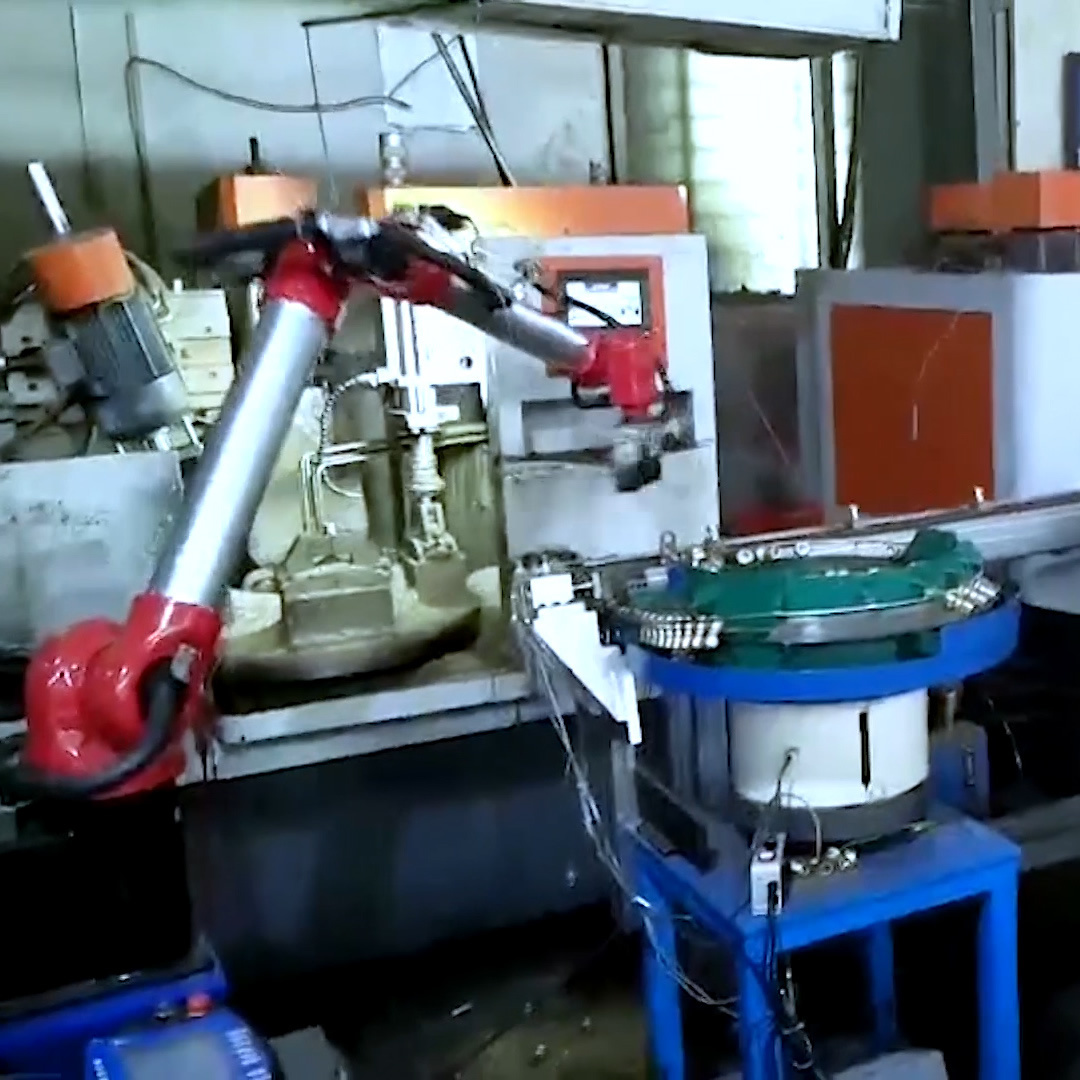

Case 3:Loading and unloading in drilling-tapping center

Small space is used and the movement is very flexible. It is specially designed for CNC high-speed drilling center. With the

internal rotating structure, it easily realizes the connection or transportation in the event of 600 of spacing with the fastest

speed and excellent avoidance.

internal rotating structure, it easily realizes the connection or transportation in the event of 600 of spacing with the fastest

speed and excellent avoidance.

Case 4:Lathe industry

Loading and unloading for watch shell

22s with five processes.

Case 5:Laptop industry

Screw embedding for HP Laptop shell

Hot-pressing for HP Laptop shell

Case 6: Automobile industry

back mirror of car carrying

degating for automotive interior parts

Hot Searches