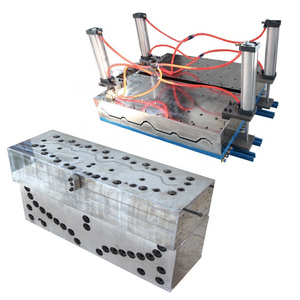

- technicist will test each mould before they leave the factory.

- Our technicist are proffessional with more than 26 years experience.So that the mold debugging time is shorter than the other factorys.

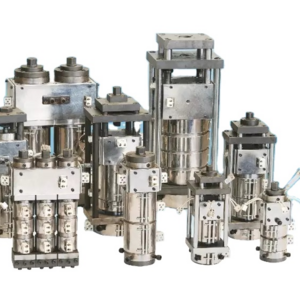

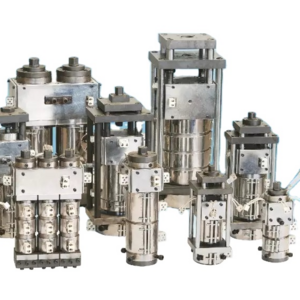

- give the whole support for customer in raw material formula,selection of extruder

- machine,mould technique and operation training on the spot.

-

supply top-quality moulds and resonable price depends on customers requests(pictures or CAD )

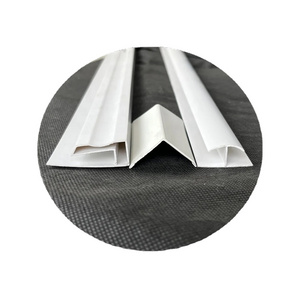

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

QS

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

30M*3M*3.5M

-

Power (kW):

-

150

-

Weight:

-

20000 KG

-

Motor:

-

SIEMENS

-

Inverter:

-

ABB

-

Product:

-

Pvc Wpc foam board

-

Raw material:

-

PVC Resin , CACO3, Additive

-

Extruder:

-

conical double screw extruder

-

Usage:

-

Kitchen & bathroom cabinet,door ,furniture

-

Control:

-

SIEMENS PLC+Touch Screen

-

Final product size:

-

1220mm*3-30mm

-

Name:

-

PVC foam board machine

-

Function:

-

PVC foam board line

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

SJSZ80/173

-

Screw diameter (mm):

-

156 mm

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

QS

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

30M*3M*3.5M

-

Power (kW):

-

150

-

Weight:

-

20000 KG

-

Motor:

-

SIEMENS

-

Inverter:

-

ABB

-

Product:

-

Pvc Wpc foam board

-

Raw material:

-

PVC Resin , CACO3, Additive

-

Extruder:

-

conical double screw extruder

-

Usage:

-

Kitchen & bathroom cabinet,door ,furniture

-

Control:

-

SIEMENS PLC+Touch Screen

-

Final product size:

-

1220mm*3-30mm

-

Name:

-

PVC foam board machine

-

Function:

-

PVC foam board line

PVC Foam Board Machine is our latest updated products. It's continuously improved on the basis of requirements and feedbacks from our customers and combined with foreign advanced technology. It shows superior performance, high reliability and practicality with its compact structure, advanced configuration and outstanding output in the production of 3-20mm thick, high-qualified PVC foam board.

2. Customers specifying freight forwarders or negotiable shipping methods!

3. Delivery Time : 40 days after getting deposit from customer.

Zhangjiagang City Qiangsheng Plastic Machinery Co.,Ltd is a leading export of plastic machine in Zhangjiagang city .The enterprise pays attention to technological improvement,actively introduces

domestic and foreign advanced technology ,improves old products and develops new ones.

The main products:two-screw extruder,single-screw extruder,sets of extruding production and

auxiliary equipments, such as PE ,PP ,PVC and PP-R plastic pipe production line, plastic profile

production line,plastic granulating line,plastic recycling line and others. Our customers are from

all over the world.