- Product Details

- {{item.text}}

Quick Details

-

MF:

-

C3H5NO)n

-

EINECS No.:

-

201-173-7

-

Place of Origin:

-

Guangdong, China

-

Type:

-

Demoulding agent

-

Brand Name:

-

JITIAN

-

Model Number:

-

J2401

-

Product name:

-

Release Agent

-

Application:

-

Metal die casting, polyurethane foam and elastomer

-

Appearance:

-

Cream White

Quick Details

-

CAS No.:

-

9004-65-3

-

Purity:

-

99.9%

-

Other Names:

-

Silicon Dioxide

-

MF:

-

C3H5NO)n

-

EINECS No.:

-

201-173-7

-

Place of Origin:

-

Guangdong, China

-

Type:

-

Demoulding agent

-

Brand Name:

-

JITIAN

-

Model Number:

-

J2401

-

Product name:

-

Release Agent

-

Application:

-

Metal die casting, polyurethane foam and elastomer

-

Appearance:

-

Cream White

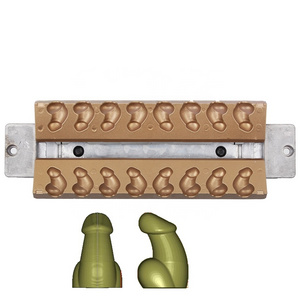

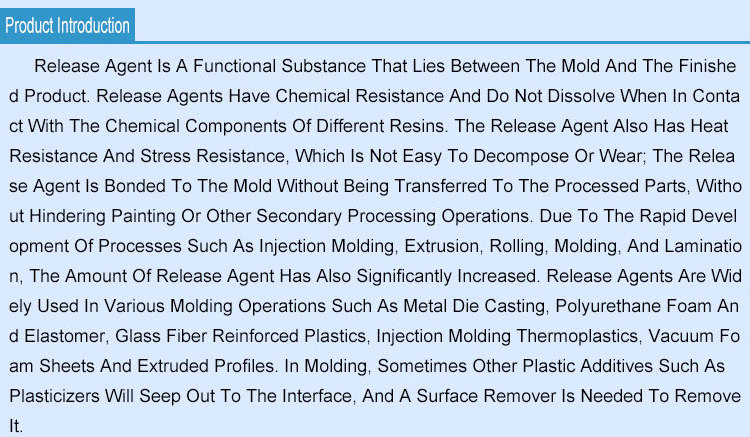

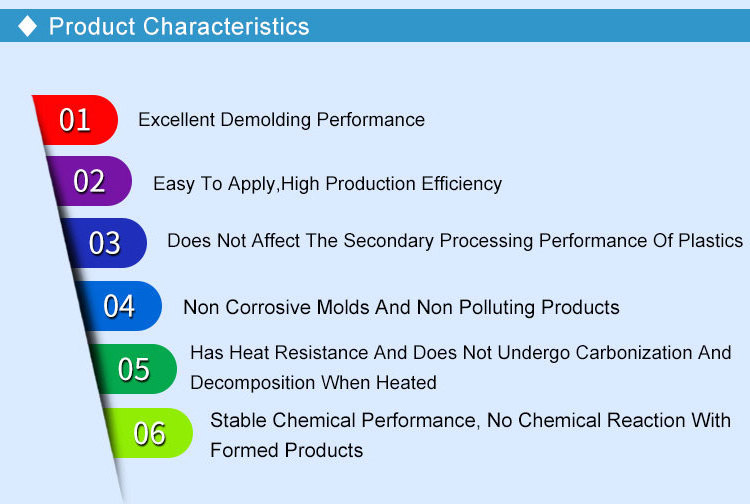

Release agent is a functional substance between the mold and the finished product. The release agent is chemically resistant and will not be dissolved when in contact with the chemical composition of different resins. The release agent also has heat resistance and stress properties, and is not easy to decompose or wear; the release agent is bonded to the mold without being transferred to the processed part, and does not hinder painting or other secondary processing operations. Due to the rapid development of injection molding, extrusion, calendering, compression molding, lamination and other processes, the amount of release agent has also increased significantly.

Release agents are widely used in various molding operations such as metal die casting, polyurethane foam and elastomers, glass fiber reinforced plastics, injection molded thermoplastics, vacuum foamed sheets and extruded profiles. In molding, sometimes other plastic additives such as plasticizers will ooze out to the interface, and a surface remover is required to remove it.

|

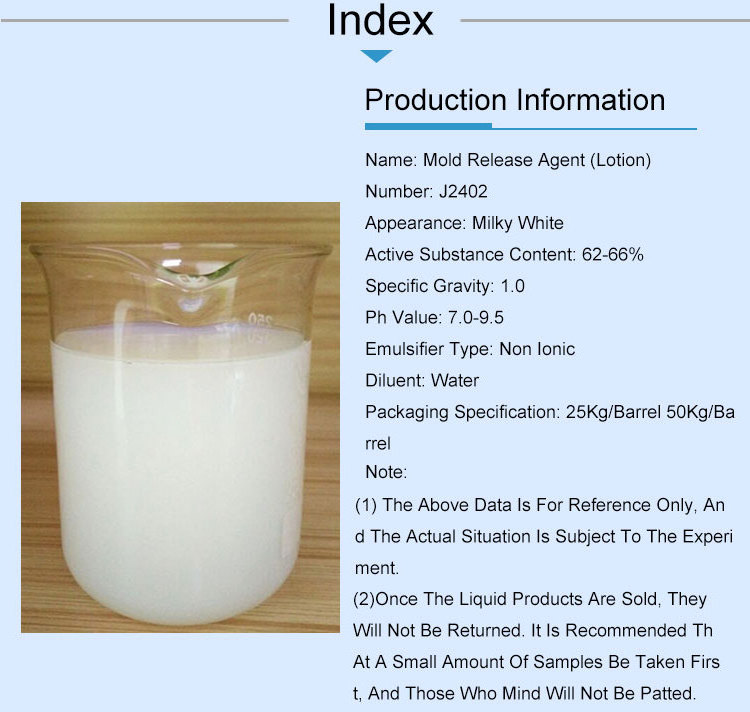

Exterior view:

|

milky white

|

|

Active matter content:

|

62-66%

|

|

Specific gravity:

|

1: 0

|

|

PH value:

|

7.0-9.5

|

|

Emulsifier type:

|

non-ionic

|

|

Thinner:

|

water

|

Hot Searches