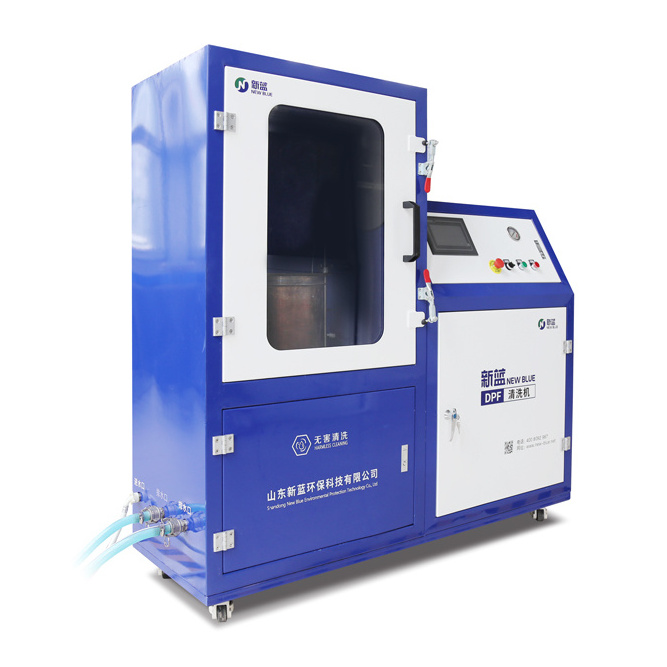

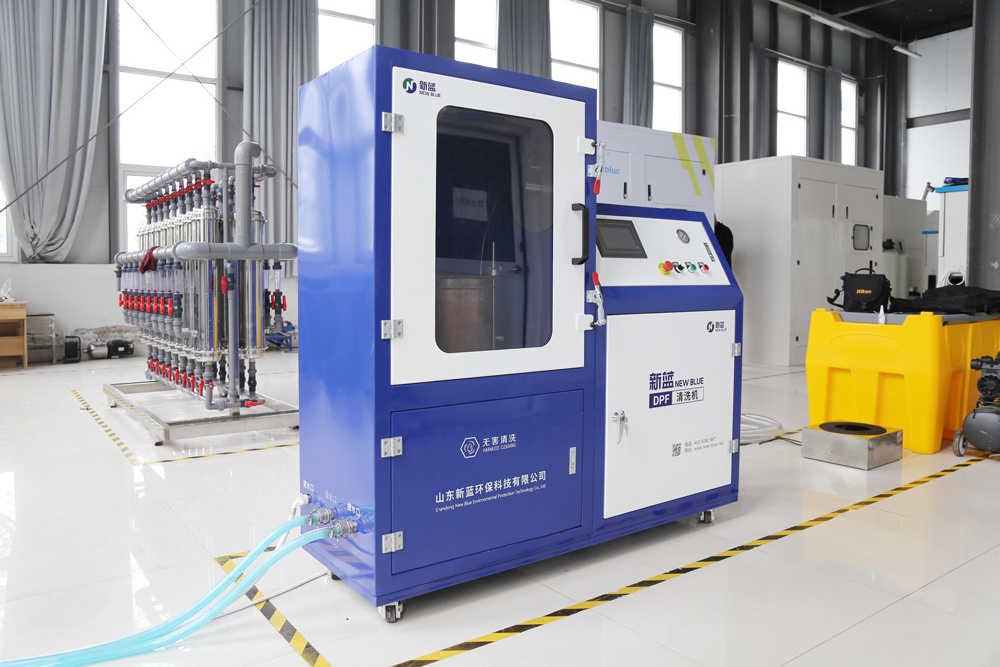

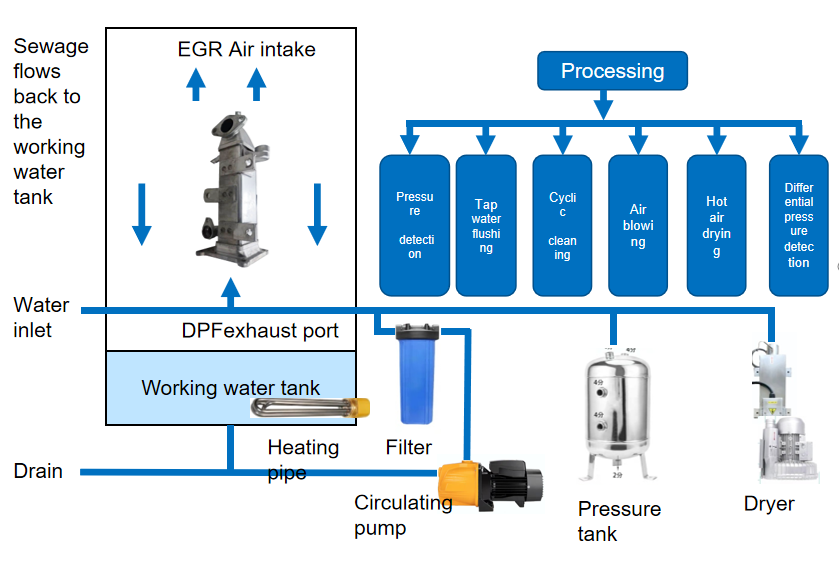

DPF reduction cleaning flow

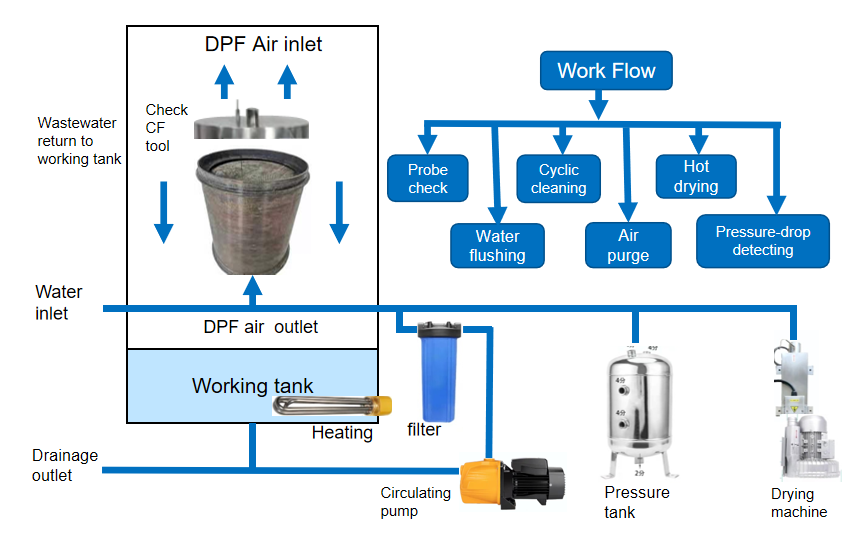

1、Examination

Use probe detector to check whether the DPF is unobstructed or fused. Discard the fused ones.

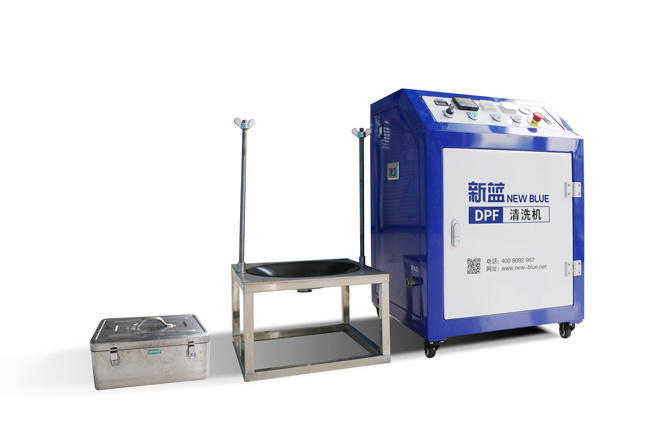

2、Flushing

Clamp the DPF onto the tooling, make air inlet upward and the outlet downward, connect the water pipe and drain pipe, open the water valve the drain valve at the same time; Use water and pulse cleaning for 3-5 minutes to flush out most of the carbon deposits in the DPF. and discharge them into the water tank for collection; Prevent plugging of filter element and reduce replacement frequency.

3、Wash

Close the drain valve, fill the tap water and special cleaning agent, switch on the heating, till the temperature reach to 50-60 ℃, turn on the circulating pump, conduct circulating cleaning for 1 minute, conduct pulse flushing once, and conduct circulating cleaning for 20 minutes. Discharge and collect the waste water after circulation; Then open the tap water valve, wash with water and pulse for 3-5 minutes, and flush out the washing liquid in the DPF.

4、Blowing

Open the pulse air for 3-5 minutes to blow out the water in the DPF.

5、Drying

Turn on the hot air fan to blow for 10-20 minutes, and dry the DPF with hot air.

6、Testing

After the drying is completed, install a back pressure detection fixture and ventilate at a constant speed for 2-5 minutes. Perform pressure difference detection on the DPF and read the values; Finally, the light source inspection is conducted to check if there is any local light source passing through the interior. If there is a light source passing through, it indicates that there is damage inside.