- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KECHUANG

-

Voltage:

-

AS CUSTOMER NEEDS

-

Dimension(L*W*H):

-

44000*1200*1500MM

-

Power (kW):

-

160

-

Weight:

-

12000 KG

-

PE PIPE MACHINE:

-

PE PIPE PRODUCTION LINE

-

PE PIPE EXTRUDER:

-

SINGLE SCREW EXTRUDER

-

BARREL & SCREW MATERIAL:

-

38CrMnALA

-

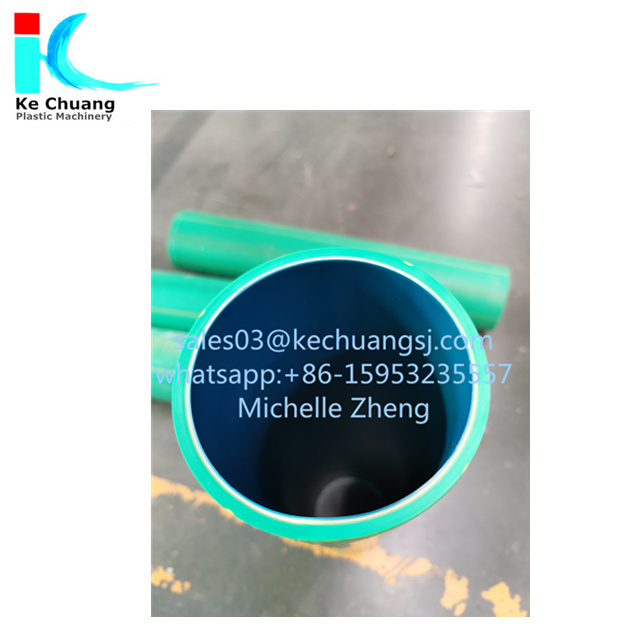

PIPE DIAMETER RANGE:

-

20-1400MM

-

OUTPUT:

-

350-500KG/H

-

POWER:

-

35-398KW

-

INVERTER:

-

ABB

-

CONTACTOR:

-

SCHNEILDER

-

PLC CONTROL SYSTEM:

-

SIMENS

-

TEMPERATURE METER:

-

RKC

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

38:1

-

Screw Speed (rpm):

-

2840 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KECHUANG

-

Voltage:

-

AS CUSTOMER NEEDS

-

Dimension(L*W*H):

-

44000*1200*1500MM

-

Power (kW):

-

160

-

Weight:

-

12000 KG

-

PE PIPE MACHINE:

-

PE PIPE PRODUCTION LINE

-

PE PIPE EXTRUDER:

-

SINGLE SCREW EXTRUDER

-

BARREL & SCREW MATERIAL:

-

38CrMnALA

-

PIPE DIAMETER RANGE:

-

20-1400MM

-

OUTPUT:

-

350-500KG/H

-

POWER:

-

35-398KW

-

INVERTER:

-

ABB

-

CONTACTOR:

-

SCHNEILDER

-

PLC CONTROL SYSTEM:

-

SIMENS

-

TEMPERATURE METER:

-

RKC

PLASTIC FIVE LAYERS PIPE EXTRUDER EXTRUSION LINE PRODUCTION LINE MAKING MACHINE PRODUCTION MACHINE PLASTIC MACHINE

PERT PIPE PRODUCTION LINE

PERT PIPE EXTRUDER

PERT PIPE MAKING MACHINE

BIGGER OUTPUT!!!!

LOWER ENERGY CONSUMPTION!!!!!!!

REASONABLE PRICE !!!

I. MAIN INTRODUCTION

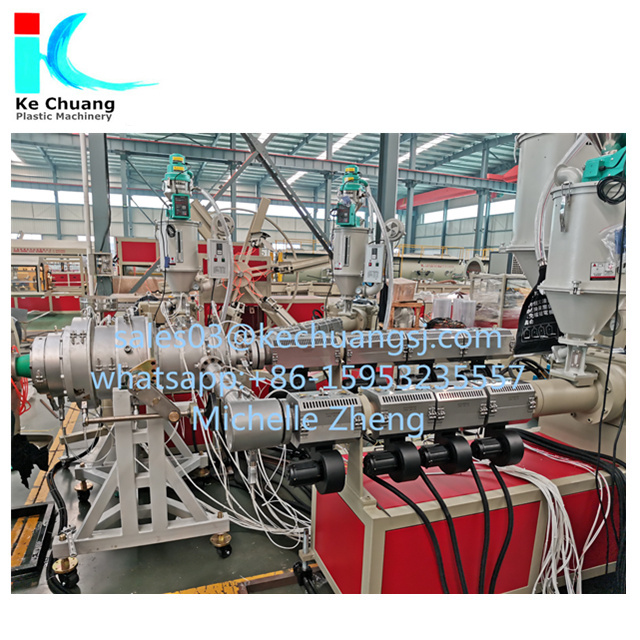

- The main machine adopts screws specially used for polyolefin. It possesses features of high production, good plasticization and stable extruding.

- Die heads of helical type and basket type are perfect for polyolefin, and can help to produce sound melting pressure, and improve the plasticization capacity. Meanwhile, stable material-flow and pressure grade can be guaranteed.

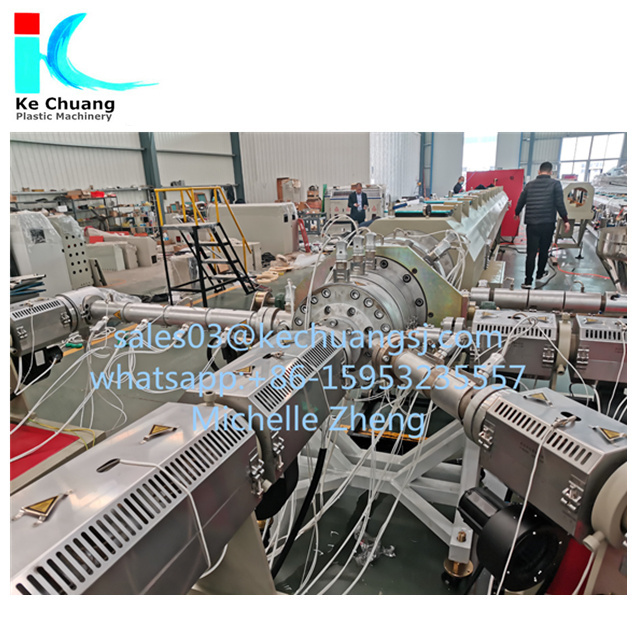

- Advanced vacuum calibrating method improves the cleanliness and hardness of surface. Reasonable high-speed sprinkling cooling water tank guarantees the pipe quality and high speed stable extruding.

- Caterpillar of the hauling machine adopts anti-abrasion alloy material, which realizes stable traction, wide frequency adjustment range and long lifespan.

- New generation auto dust-free cutting blade realizes smooth cutting surface, high precision and low noise

- It is equipped with automatic vacuum appending machines and automatic constant temperature drying hopper.

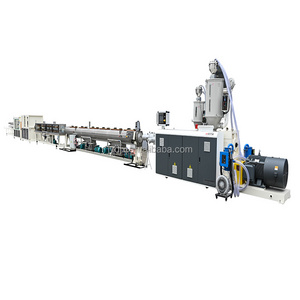

| Model | Pipe Diameter | Extruder | Output | Installation Power | Extruder Power |

| (mm) | (kg/h) | (kw) | (kw) | ||

| SJ45 | 16~32 | SJ45/30 SJ25/25 | 30~60 | 40 | 22 |

| SJ65 | 20~75 | SJ65/33 SJ25/25 | 80~120 | 65 | 37 |

| SJ75 | 50~160 | SJ75/33 SJ25/25 | 80~150 | 150 | 75 |

| SJ90 | 75~250 | SJ90/33 SJ25/25 | 280~350 | 200 | 110 |

| SJ75 | 160~315 | SJ75/38 | 550~800 | 280 | 160 |

| SJ150 | 315~630 | SJ150/33 SJ30/25 | 550~800 | 420 | 285 |

Configuration:

Plastic automatic loader →Hopper plastic dryer→ Single screw extruder (Mark line extruder)→ Mould and calibrator → Vacuum forming machine → Water cooling tank → Haul off machine → Cutting machine → stacker

III. MAIN FEATURES:

- extruder: adopting conical twin-screw extruder, unique designed screw, realizing shorting plasticizing time, good compounding and excellent plasticization.

- gearbox: adopting super quality gear box and reducer, with nice outline, stable running, low noise and long service time.

- extruding barrel temperature controlling system: adopting cast aluminum heaters with stainless steel covers, wind cooling system, ensuring good features of cooling and heating, precision temperature controlling.

- screw and barrel: screw-core installing with internal temperature controlling system, barrel equipped with vacuum degassing system, can get rid of the waste gas from the raw material which can guarantee super quality of the products.

- driving system: adopting A.C motor, using FUJI or ABB inverters which provide stable torque output and various speed.

- vacuum calibrating tank: with two vacuum chambers which can make sure the perfect roundness of the pipe, spraying water cooling, equipped with temperature controller, realizing automatic discharging the water, the main body of the tank make of stainless steel, long service time.

- haul-off machines: 2 laws, 3 claws, 4 claws, 6 claws and 8 claws are provided to manufacture various pipes, haul-off speed governed by the FUJI or ABB inverter.

- cutting unit: saw cutting and planet saw cutting, with dust collection system.

- stacking unit: automatic overturning system, can freely fix the length of the pipe.

- controlling system: manual controlling cabinet or SIEMENS PLC touch screen controlling

Plastic film packaging or can be customized.

Our Factory:

KECHUANG Is a high-technique joint-stock company,which is relevant to high-molecule material,and engaged in developing,designing and manufacturing all kinds of plastic and mechanic.

Base on the developing tactic of “quality and credit make foundation stable,meanwhile,speed and technique create difference”, the company scale extends more and more large,and its technique power is more and\ more strong. The company has an independent studying & developing team,and cooperates with high education school during long time, the most competitive equipment is valued by all fields. Presently, the products of this company is popularly used all over the world,especialy export Russia, east-south Asian, middle-east and Africa, ect.