- Product Details

- {{item.text}}

Quick Details

-

Power:

-

according to the size

-

Weight:

-

acording to the size

-

Dimension(L*W*H):

-

customized

-

Certification:

-

CE ISO SGS

-

Heating way:

-

Steam Heating/electric heating

-

Sterilizing way:

-

Water Immersion/water spray

-

Function:

-

High Temperature High Pressure Sterilizing

-

Control system:

-

Automatic

-

Advantage:

-

High Efficiency

-

Application:

-

Metal Cans/pouch/bottles

-

Design pressure:

-

0.47Mpa

-

Machine name:

-

Small Autoclave Food Sterilizer

-

Design Temperature:

-

147 Degree Centigrade

-

Material:

-

Stainless Steel SUS304

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Ritong

-

Voltage:

-

380V/220V

-

Power:

-

according to the size

-

Weight:

-

acording to the size

-

Dimension(L*W*H):

-

customized

-

Certification:

-

CE ISO SGS

-

Heating way:

-

Steam Heating/electric heating

-

Sterilizing way:

-

Water Immersion/water spray

-

Function:

-

High Temperature High Pressure Sterilizing

-

Control system:

-

Automatic

-

Advantage:

-

High Efficiency

-

Application:

-

Metal Cans/pouch/bottles

-

Design pressure:

-

0.47Mpa

-

Machine name:

-

Small Autoclave Food Sterilizer

-

Design Temperature:

-

147 Degree Centigrade

-

Material:

-

Stainless Steel SUS304

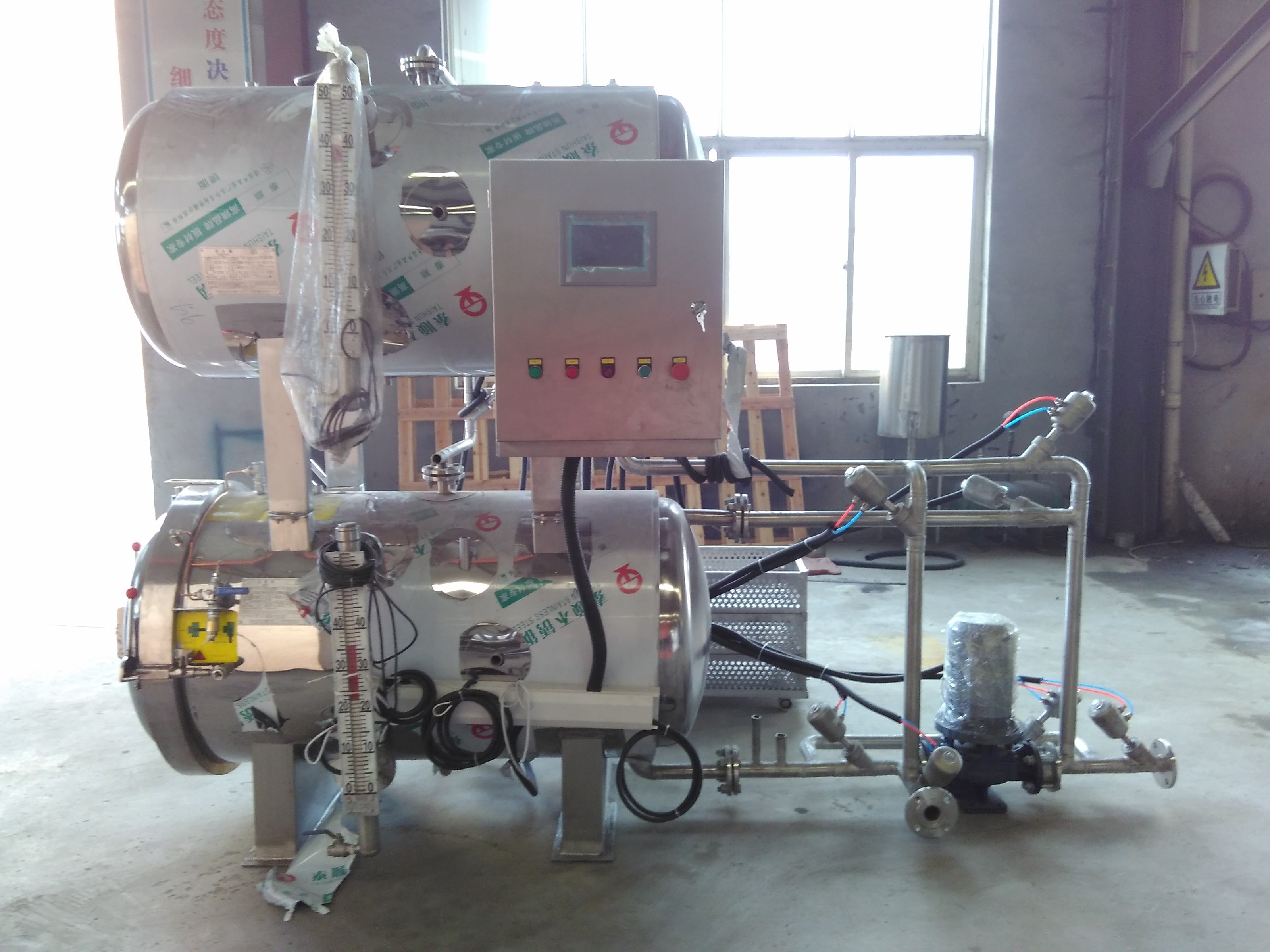

Small Autoclave Food Sterilizer Price For Sale

Small Autoclave Food Sterilizer

Equipment features

1. It is used for the laboratory type food producers to develop new products, set sterilization formula for new products and simulate

practical production environment to the maximum.

2.It tests FO value for batch production and defines the sterilizing formula to reduce consumption of the finished products.

It improves finished product rate during batch production.

3.It equips electric heating system on the basis of traditional spraying type retort and provides heat energy to sterilizing process.

4. Multiple sterilizing types can suit different food products.

Application

Metal container: tinplate cans, aluminum can.

Plastic container: PP bottle , HDPE bottle.

Technical parameter

|

Model |

RT-600 |

RT-600 |

RT-700 |

RT-800 |

| Diameter(mm) |

800 |

1000 |

120 |

1500 |

|

Design temperature |

147°C |

|||

|

Material |

SUS304/Q235B |

|||

|

Design pressure |

0.35 Mpa |

|||

|

Experiment pressure |

0.44Mpa |

|||

|

MODEL |

DIAMETER |

CYLINDER LENGTH |

TOTAL LENGTH |

PRODUCTIVITY |

BOILER MODEL |

CAPACITY |

|

700 |

0.7 |

1.2 |

1.7 |

120-150kg |

0.1 |

0.7 |

|

800 |

0.8 |

1.5 |

2.3 |

200-250kg |

0.2 |

1.1 |

|

900 |

0.9 |

1.8 |

2.5 |

300-350kg |

0.2 |

1.3 |

|

1000 |

1 |

2.2 |

3.0 |

500-550kg |

0.3 |

2.1 |

|

1200 |

1.2 |

3 |

3.8 |

800-1000kg |

0.5 |

4.0 |

Workshop

PLC

Procedures designed procedural programming programmable intelligent operation, can store the sterilizing data for long time, and can print the pressure and temperature curve; big volume computer store, can edit the sterilizing craft, when operating can show the CG flow, PLC brand is Siemens.

Insulation process of the autoclave

Firstly, drilling holes used in the following steps in the tank in advance.

Secondly, put steel rings welded on the tank. The rings are used to fix the mineral wool.

Thirdly, use mineral wool, the material of which is aluminium silicate, to wrap around the tank

body for preservation.

Lastly, use insulation board to be welded around the tank. It is finished.

Fault Detection

Detection of cracks or defects in metallic materials or components X-ray inspection

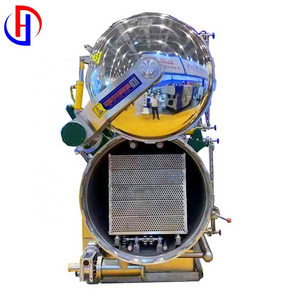

Finished machine photos

Show room