- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Model

-

Power (kW):

-

5.5 kW

-

Warranty:

-

1 Year, 12 Months

-

Certification:

-

ISO9001:2008

-

Name:

-

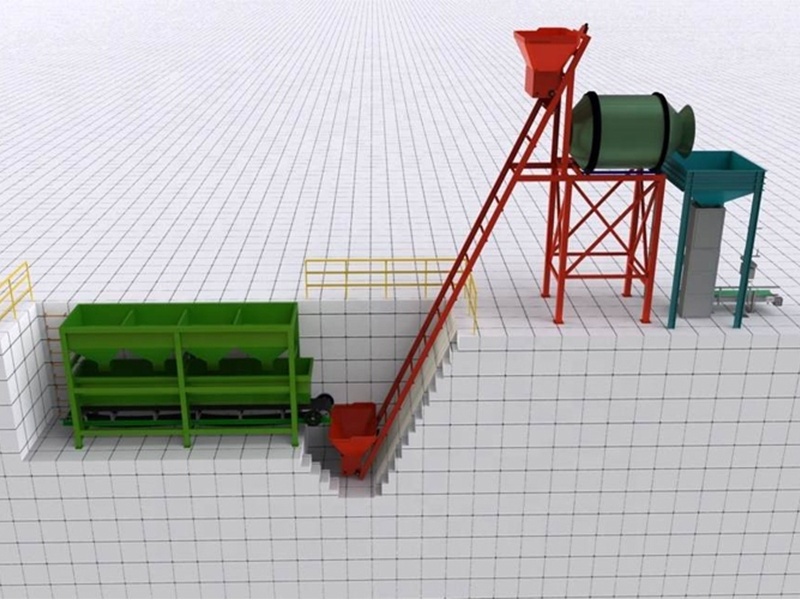

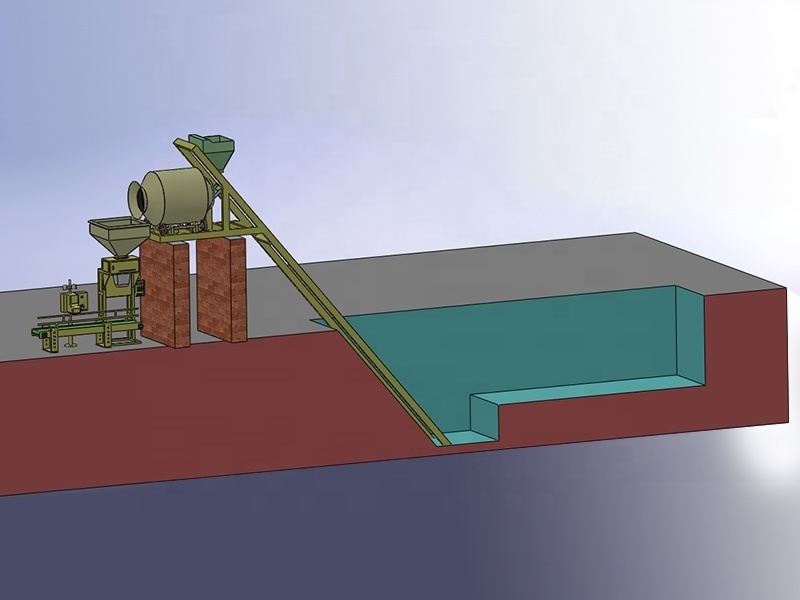

BB Fertilizer Mixer

-

Color:

-

Orange/Customized

-

Type:

-

Mixing Equipment

-

Usage:

-

Fertilizer Mixing

-

Material:

-

Various dry and wet materials

-

Crawl Conveyor Volume:

-

0.7m3

-

Diameter:

-

Customized

-

including:

-

Crawl Conveyor and steel frame

Quick Details

-

Barrel Volume (L):

-

2 L

-

Max. Loading Volume (L):

-

1 L

-

Max. Loading Capacity:

-

5-10 t/h

-

Weight (KG):

-

1500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Model

-

Power (kW):

-

5.5 kW

-

Warranty:

-

1 Year, 12 Months

-

Certification:

-

ISO9001:2008

-

Name:

-

BB Fertilizer Mixer

-

Color:

-

Orange/Customized

-

Type:

-

Mixing Equipment

-

Usage:

-

Fertilizer Mixing

-

Material:

-

Various dry and wet materials

-

Crawl Conveyor Volume:

-

0.7m3

-

Diameter:

-

Customized

-

including:

-

Crawl Conveyor and steel frame

Purpose and advantages of a machine:

It is mainly used in organic fertilizer, compound fertilizer or under the dust collector of thermal power plant. It can also be used in chemical metallurgy, mining, building materials and other industries.

1. the mixing efficiency is high and the area is small.The spiral blade adopts high – wear special alloy.

2. single shaft mixer adopts reducer transmission, which is stable and has low noise.

3. It has reasonable structure. Its feeding is from the top, and the discharging is from the bottom.

4. The joint surfaces are tightly sealed and run smoothly.

Characteristics of Performance:

1.The mixing efficiency is high and the area is small.The spiral blade adopts high – wear special alloy.

2.Adopts reducer transmission, which is stable and has low noise.

3.It has reasonable structure. Its feeding is from the top, and the discharging is from the bottom.

4.The joint surfaces are tightly sealed and run smoothly.

Working Principle:

A single shaft mixer rotates with a shaft that adds a spiral blade. Adding water and mixing with water while conveying dry ash and other powdery materials. Humidification of dry ash powder to achieve the purpose of adding wet materials to dry ash without effusion.

|

Model

|

Power

|

Lifting Power

|

Capacity

|

|

SXBM-1525

|

5.5KW

|

1.5KW

|

5-10t/h

|

1. Our company’s products are strict in accordance with national standards, contracts and technical specifications to choose the best solutions. We also do comprehensive tracking and monitor the quality of the process and testing to ensure product quality.

2. We will provide one year quality guarantee and free on-site service for our products. After the warranty expires, we will continue to provide life-long maintenance but collect appropriate maintenance fees as the case.

3. We will provide customers product manual, product qualification certificate, packing list and related technical information. If customers need, we can also provide installation service oversea.

4. Does not belong to free warranty obligations:

Belonging to the following conditions this product failure or damage, whether or not in the free warranty period, not in the list of free warranty.

a. The whole or parts of products are already beyond the warranty period;

b. Damage or failure is caused by products erroneously used or incorrect installation, maintenance and custody;

c. Damage or failure is caused by beyond our certification services, personnel to install, repair, alteration and demolition;

d. Damage or failure is caused by anybody outside of customers’ company

Q: Are you trading company or manufacturer ?

A: We are a manufacturer with a history over 30 years and have a professional team.So we have great advantages in controlling product quality & delivery time.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-25 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment≤1000USD, 100% in advance. Payment>1000USD, 50%TT as deposit, remaining 50%TT before delivery.

If you have another question, please feel free to contact me!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|