•

"2D graphical touch screen programming mode

•

3D visualisation in simulation and production

•

17″ high resolution colour TFT

•

Full Windows application suite

•

Delem Modusys compatibility (module scalability and adaptivity)

•

USB, peripheral interfacing

•

User specific application support within the controllers multitasking environment

•

Sensor bending & correction interface

•

Profile-TL offline software

- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

140 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

BOSSER

-

Year:

-

2022

-

Weight (KG):

-

8500

-

Motor Power (kw):

-

7.5 kw

-

Product name:

-

Hydraulic Press Brake Machine

-

Raw Material:

-

Metal Sheet

-

Type:

-

Hydraulic Bending Tools

-

Power:

-

7.5kw

-

Application:

-

Steel Sheet Plate

-

Function:

-

Steel Metal Bending

-

CNC Control system:

-

Delem Holand

-

Hydraulic System:

-

Bosch Rexroth Germany

-

Main Motor:

-

Siemens Germany

-

Electrical components:

-

Schneider

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

140 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

BOSSER

-

Year:

-

2022

-

Weight (KG):

-

8500

-

Motor Power (kw):

-

7.5 kw

-

Product name:

-

Hydraulic Press Brake Machine

-

Raw Material:

-

Metal Sheet

-

Type:

-

Hydraulic Bending Tools

-

Power:

-

7.5kw

-

Application:

-

Steel Sheet Plate

-

Function:

-

Steel Metal Bending

-

CNC Control system:

-

Delem Holand

-

Hydraulic System:

-

Bosch Rexroth Germany

-

Main Motor:

-

Siemens Germany

-

Electrical components:

-

Schneider

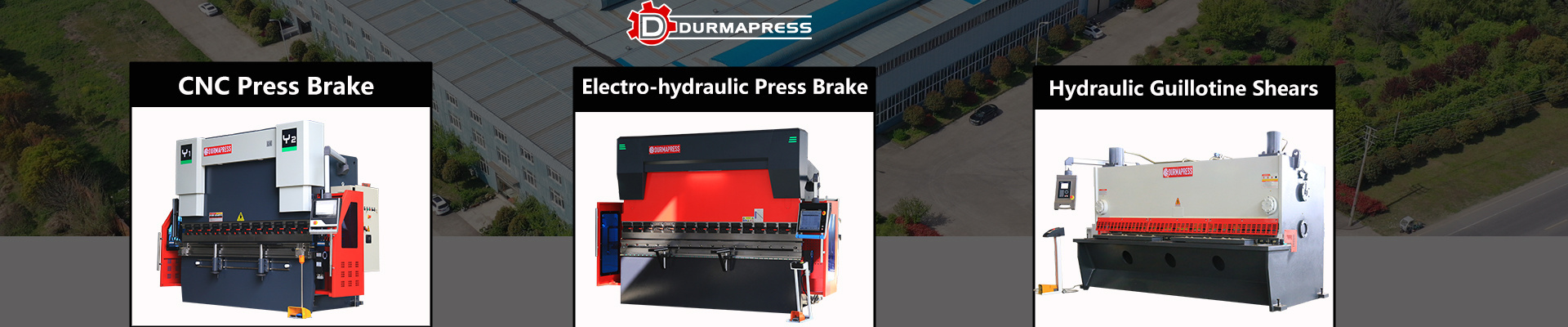

CNC Press Brake

The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric

cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in

sheet metal bending, such as automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway

vehicles and other industries.

Main Configuration

DELEM DA66T CNC Controller

Adopting HIWIN ball screw and linear guide rail, accuracy 0.01mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Automatic Mechanical compensation

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric

cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in

sheet metal bending, such as automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway

vehicles and other industries.

Main Configuration

DELEM DA66T CNC Controller

Adopting HIWIN ball screw and linear guide rail, accuracy 0.01mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Automatic Mechanical compensation

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

CNC Controller System

DELEM DA66T Touch CNC System

Advantage:

Advantage:

• Safe and fast tool change

• Can be used without modifying Europe type punches

• Red Button- Release the Punch Toolings easily

• Front clamp - vertical tool change

• Rear clamp - horizontal tool change

• Can be used without modifying Europe type punches

• Red Button- Release the Punch Toolings easily

• Front clamp - vertical tool change

• Rear clamp - horizontal tool change

• Durable body hardened to 28-32 RCS.

• Mounting available for all types of press brakes: OEM bolt down design; Aftermarket mounting options for American and European

stylepress brakes.

• Hydraulic clamping system adjusts with a remote control or CNC direct to machine control: 8 mm (.315 in) diameter pins hold dies

every

• Mounting available for all types of press brakes: OEM bolt down design; Aftermarket mounting options for American and European

stylepress brakes.

• Hydraulic clamping system adjusts with a remote control or CNC direct to machine control: 8 mm (.315 in) diameter pins hold dies

every

|

Bending Capability

|

80/3200

|

100/3200

|

100/4000

|

125/3200

|

125/4000

|

160/3200

|

160/4000

|

|

Nominal Force(KN)

|

800

|

1000

|

1000

|

1250

|

1250

|

1600

|

1600

|

|

Worktable Length(mm)

|

3200

|

3200

|

4000

|

3200

|

4000

|

3200

|

4000

|

|

Column Distance(mm)

|

2490

|

2490

|

3000

|

2490

|

3000

|

2490

|

3000

|

|

Throat Depth(mm)

|

250

|

320

|

320

|

320

|

320

|

320

|

320

|

|

Ram Stroke(mm)

|

120

|

120

|

120

|

120

|

120

|

180

|

180

|

|

Main Motor Power(KW)

|

5.5

|

7.5

|

7.5

|

7.5

|

7.5

|

11

|

11

|

View more products,you can click product keywords...

|

Main Products

|

|

|

||

|

Press Brake

|

Shearing Machine

|

Fiber laser Cutting Machine

|

||

|

CNC V Grooving machine

|

Ironworker

|

notching machine

|

||

|

power press machine

|

roof forming machine

|

press brake die

|

||

Maanshan Durmapress Machinery Technology Co,. Ltd.

DURMAPRESS( Branch Brand : Bossorlaser)is a famous brand company in China ,which is dedicatedto development, production and sales of sheet metal equipment(Press Brake , Shearing Machine , lrowworker,Punching machineand ect).Located in Maanshan, Anhui Province, After 15 years development, it has been a famous and influential modern enterprise which owns two Subsidiary corporations -Maanshan Durmapress Machinery Technology Co.,Ltd and NanjingBosslaser CNC Technology Co.Ltd (Professional for Fiber Laser Cutting Machine Adhering to the advanced European design concept, Boslaser follow the technology of Belgian R&.D center.combine with theactual needs of customers, and make well-structured and high-quality sheet metal fabrication equipment. Most importantly, itmakes us be the professional sheet metal processing equipment supplier.

FAQ

Q: How to get a accurate quotation from us ?

A:Please provide us the details of material , max thickness and max width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with

postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

Right and left, backside all with safetyguard guarantees operations safety.

A:Please provide us the details of material , max thickness and max width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with

postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

Right and left, backside all with safetyguard guarantees operations safety.

Our Service

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

3.Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. Machine warranty is 5 years.

1.Installation Services

Installation Services are available with all Our machines. We dispatch technician to customer's factory for installation and

preoperation of machines. ( Customers only need to pay the airfare and hotel )

Installation Services are available with all Our machines. We dispatch technician to customer's factory for installation and

preoperation of machines. ( Customers only need to pay the airfare and hotel )

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

3.Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. Machine warranty is 5 years.

Hot Searches