- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

25*7m

-

Power (kW):

-

120kw

-

Weight (KG):

-

50000 kg

-

Application:

-

Plywood Production

-

Function:

-

Venneer Peeling

-

Power(W):

-

180KW

-

Showroom Location:

-

Russia

-

Marketing Type:

-

Hot Product 2019

-

Machinery Test Report:

-

Provided

-

Certification:

-

CE

-

Size:

-

25000*7000*3000mm

-

Total Power:

-

120kw

-

Weight:

-

50000kg

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JINLUN

-

Voltage:

-

380V/220A

-

Dimension(L*W*H):

-

25*7m

-

Power (kW):

-

120kw

-

Weight (KG):

-

50000 kg

-

Application:

-

Plywood Production

-

Function:

-

Venneer Peeling

-

Power(W):

-

180KW

-

Showroom Location:

-

Russia

-

Marketing Type:

-

Hot Product 2019

-

Machinery Test Report:

-

Provided

-

Certification:

-

CE

-

Size:

-

25000*7000*3000mm

-

Total Power:

-

120kw

-

Weight:

-

50000kg

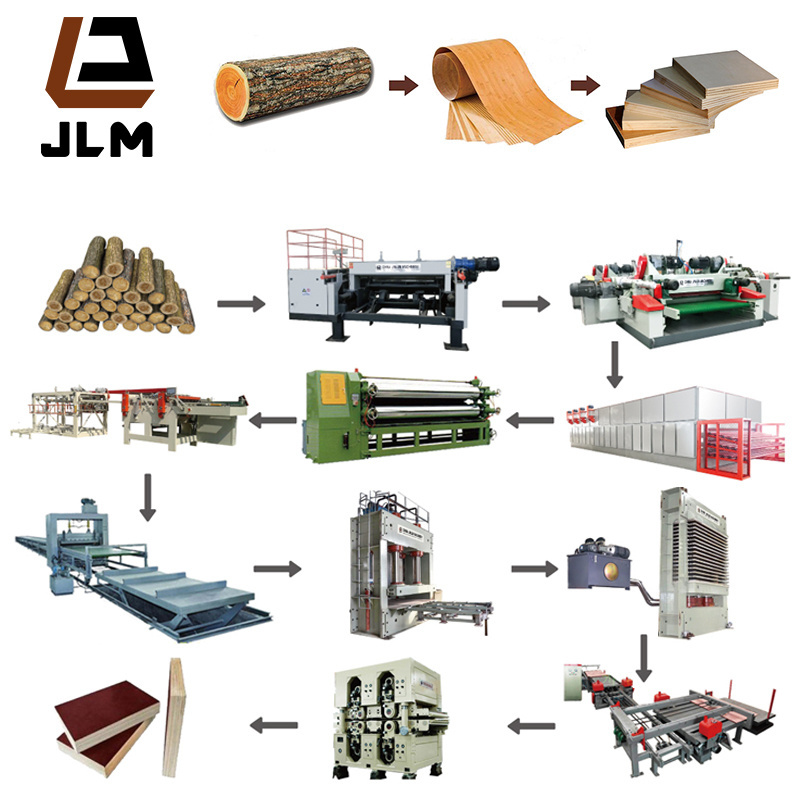

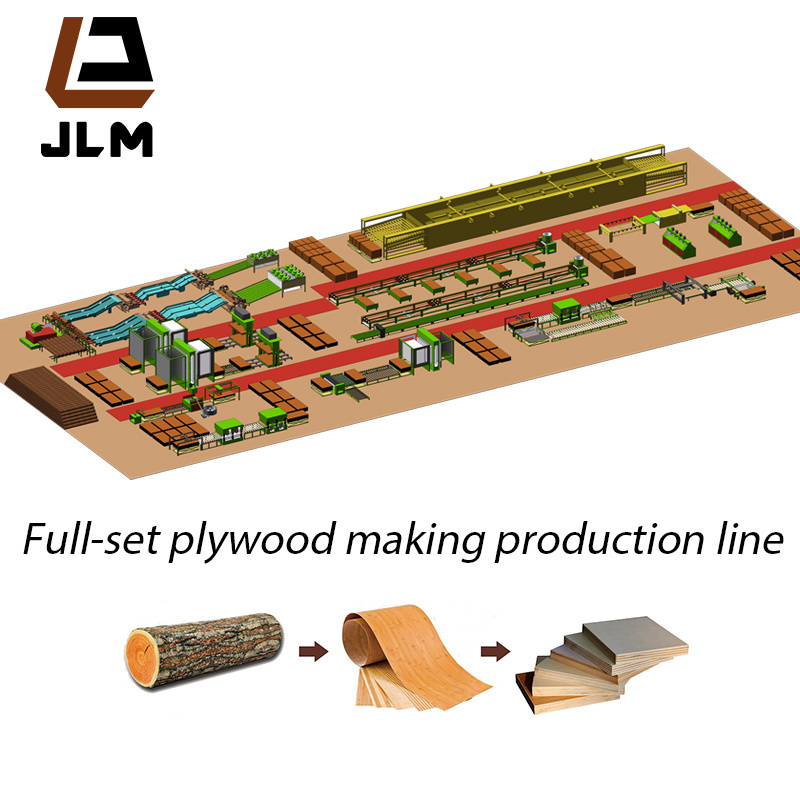

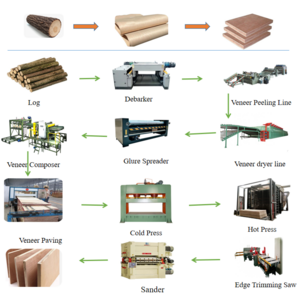

Veneer production machine

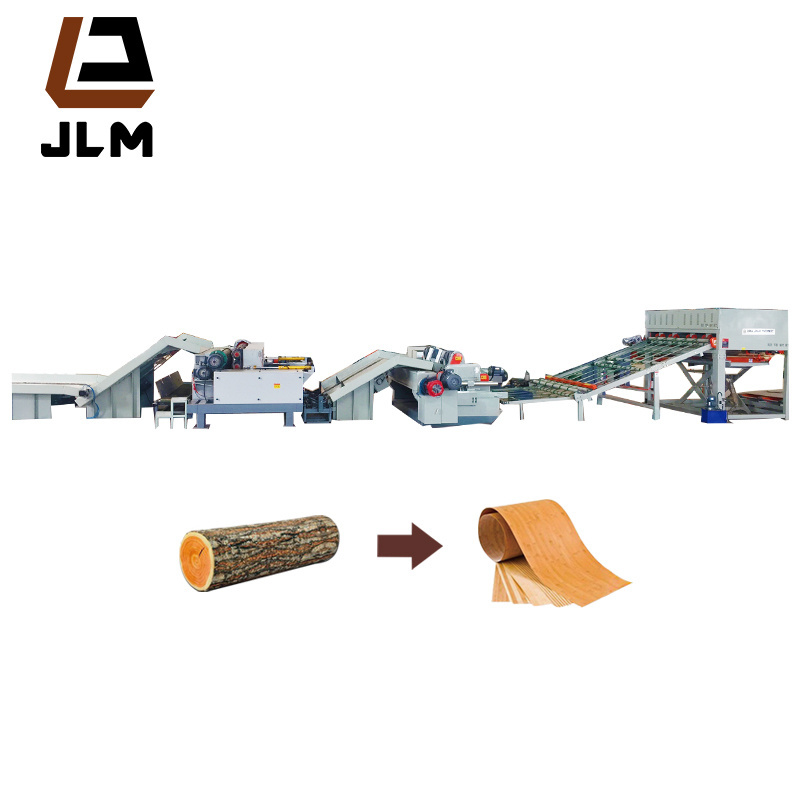

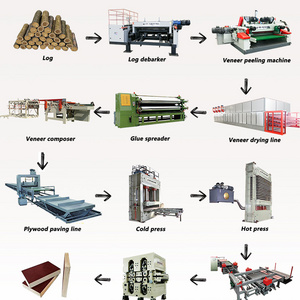

wood log debarking machine

is one of the main equipment for producing plywood . The appearance of the hydraulic ringing machine not only improves the working efficiency of the logs, but also requires one person to operate.save time and high efficiency. more and more debarker instead of manual remove skin.

CNC venner peeler is important equipment in plywood production line and venner production line. it main to peeling off small diameter wood and peeling plywood core plate, automatic peeling, cutting board, fast,

provincial labor 2-3 people, Veneer size can be set to change, fully automated production. For poplar, pine, birch and so on.

4feet and 8feet spindleless veneer peeling and cutting production line is one more automatic production process In the production of plywood, this line was composed of log feeder, log debarker machine , veneer peeling peeling lathe , automatic stacker, the whole only two workers to operate, save time ,high efficiency.

our Machine max diameter can make to 800mm ,so dont worry wood problem.usually production line

daily out 45-65 cbm.

Spindle veneer peeling machine suit big wood diameter, when your log more than 800mm ,suggest using this machine,usually no-card peeler main peeling cutting face veneer .

veneer drying line

Veneer drying line is important machine in plywood processing, when you peeling get fresh veneer, for long stock ,need remove water and moisture,so you need core veneer dryer or drying line. this Mahcine length and width is according to your veneer size and outpu,so if you want, need tell us these information.

For drying line, there are roller type drying line (suit for core veneer), Mesh belt type drying line (suit for face veneer and core veneer,but cost is high), Wire rope drying line (face veneer, low cost),so choose up to your veneer and output .

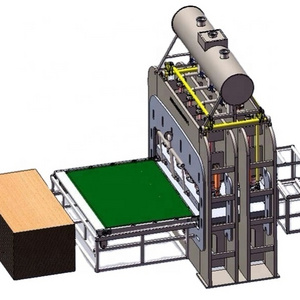

Pre-press machine +hot press machine

Cold Press machine is a fixed effect on the glue ; Multi-layer hot press in the realization of the treatment of based board will be high temperature heat treatment, so that the molding process plays an important role in the pressure plate pressure, the relationship between the adhesive to the glue, so choose the right press is the customer needs to consider. plywood press machine also used in eco-board, blockboard and other wood-based panels.

core veneer composer machine

The core veneers (1.0-4.0mm thickness panels) after drying may have different length and thickness,and the shapes may get irregular, this

core veneer composing machine

can detect width, thickness, cavities of the core veneer , trimmed, glued, composed, cut to length and stacked automatically. With this machine, the core veneer with different sizes can be composed in one whole sheet.

Glue spreader machine

Plywood paving line

Automatic CNC plywood paving line machine to achieve automatic plating, sawing, board.

Automatic plywood cutting saw

sanding machine

Pre-Sales Service

* Inquiry and consulting support.

* Video reference and projects Design

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.