- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QINGDAO HEGU

-

Voltage:

-

3P/380V/50HZ or as local

-

Dimension(L*W*H):

-

20*3*3.5m

-

Power (kW):

-

55

-

Weight:

-

10000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Extruder model:

-

SZSJ-65/132

-

Main motor power:

-

37kw

-

Motor brand:

-

Siemens

-

Output capacity:

-

150-200kg/h

-

Electrical component:

-

ABB, Omron, RKC, Shneider etc.

-

Color:

-

customized

-

Application 1:

-

Flooring , decking , fencing etc

-

Application 2:

-

broom stick, widnow and door profile, photo frame etc

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

20 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QINGDAO HEGU

-

Voltage:

-

3P/380V/50HZ or as local

-

Dimension(L*W*H):

-

20*3*3.5m

-

Power (kW):

-

55

-

Weight:

-

10000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Extruder model:

-

SZSJ-65/132

-

Main motor power:

-

37kw

-

Motor brand:

-

Siemens

-

Output capacity:

-

150-200kg/h

-

Electrical component:

-

ABB, Omron, RKC, Shneider etc.

-

Color:

-

customized

-

Application 1:

-

Flooring , decking , fencing etc

-

Application 2:

-

broom stick, widnow and door profile, photo frame etc

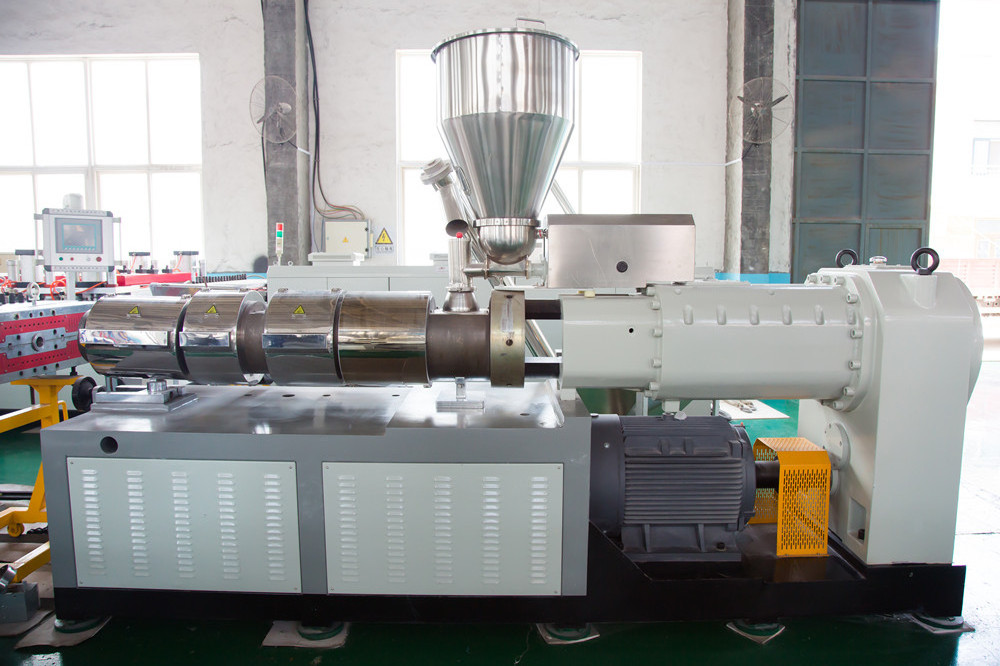

This PVC/WPC wood plastic composite profile extrusion machine is specializing in producing PVC/WPC wood plastic composite plastic profiles including windows and doors, decorative plates,foam profile etc.By absorbing advanced technology from abroad, our company developed the large plastic profile extrusion line, which is equipped with conical double screw extruder, and it possesses the advantage of high degree automation, stable performance,high output and efficiency, etc.

PVC powder is used as raw mateiral for producing various sorts of the mentionedplastic profiles as profiles for doors and windows, decorative profiles etc.

As the extrusion lines is optimized designed by referring to the lastest overseas technology, it bears the features of even plasticization, low cutting rate,high output , and long lifespan, etc.

The temperature controlling instrument is introduced from aboard. In addition, the vacuum pumpand traction engine of the auxiliary machines are quality products which can be maintained easily.

If changed certain screw and mould , this profile extrusion line can directly extrude foaming profiles.

To match with different moulds , the shape fixing platform if 4m,6m,8m, or 11m, etc can be chosen accordingly.

This extrusion line can produce: window and door profile , photo frame, decking, flooring, fencing,broom stick etc.

We have this machine in stock now, we welcome you come to visit us and see running machine.

This line consists of twin conical screw extruder, mould, calibrating table , haul off machine ,cutting machine and stacker.

Name: twin conical screw extruder

Original: Qingdao ,Shandong,China

Special screw for PVC WPC material, Siemens motor, ABB converter. Other electrical component-----Omron, Shneider.

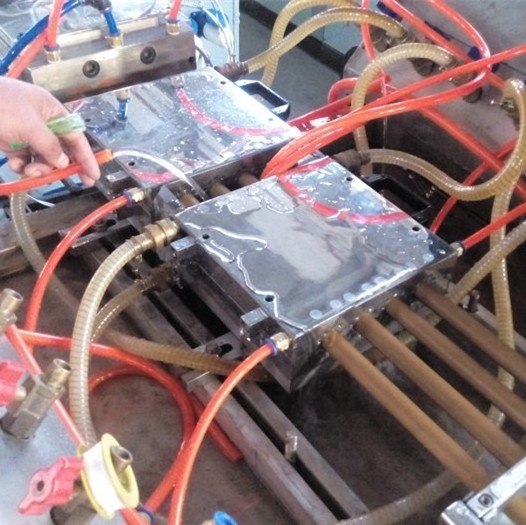

Name:

Mould

Original:

Qingdao,Shandong, China

Mould size customized by ccustomer

Name:

Calibrating and cooling table

Original:

Qingdao ,Shandong, China

Name: Haul off and cutting machine

Original:

Qingdao ,Shandong, China

1,Single wall orrugated pipe machine

2,WPC profile machine./PVC window and door profile machine

3, WPC door machine

4, PVC WPC foam board machine.

5, PP hollow sheet machine

6, PE pipe machine

7, PVC pipe machine

8, PVC fiber reinforced hose making machine

9, PVC sheet machine

10, ABS/HIPS/PE/PP sheet machine.

11, Other auxiliary devices, such as crusher, miller, mixer.

Pre-sale services

1.Provide the free consultation of the machine

2.Provide the standard device and the flow chart

3.According to the clients' special requirement, offering the reasonable plan and free design helping to select the machine

4.Welcome to visit our factory or the domestic clients' factory.

Services during the sales

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Inspect the machine before leaving the factory.

3.Send our experienced workers and engineer to your factory for installing and adjusting all the machine

4.Train the first-line operator.

5.Provide the basic formula

After sale services

1.One year warranty

2.24 hours online service

3.Engineers available to service machinery overseas

4.Provide technical exchanging