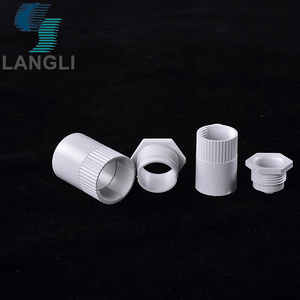

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

steel,bronze,brass,graphite,PTFE,POM,iron,ect

-

type:

-

Sleeve,Flange,Thrust,Slide Pad,Washer

-

Product Shape:

-

Cylinder,Sleeve,Flanged,Thrust pads,Skateboards, or Customized Bushing

-

Bush layer:

-

PTFE,POM plastic,Tin,Zinc,Bronze coating,Galvanized,Dacroment

-

Packing:

-

Print mark logo+Anti-rust oil+Plastic films+Plastic bag+Carton+Pallet

-

Size:

-

08,08mm to 190,200mm ; Certification ISO/TS16949

-

Item model:

-

DU,DX,FB090,FB092,JDB,SF-1,SF-2,JCB,FU,FR,FZ,Roller ball transfer unit

-

Item model2:

-

DYB 500 JDB JF800 JF-800 SJ

-

Shipping info.:

-

By sea,By air,By express,all available.(DHL,FEDEX,UPS,TNT,TOLL,ect.)

-

Service:

-

Offer high-tech reliable products,And reply you at the first

Quick Details

-

Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

-

Precision Rating:

-

high

-

Place of Origin:

-

ZHE

-

Material:

-

steel,bronze,brass,graphite,PTFE,POM,iron,ect

-

type:

-

Sleeve,Flange,Thrust,Slide Pad,Washer

-

Product Shape:

-

Cylinder,Sleeve,Flanged,Thrust pads,Skateboards, or Customized Bushing

-

Bush layer:

-

PTFE,POM plastic,Tin,Zinc,Bronze coating,Galvanized,Dacroment

-

Packing:

-

Print mark logo+Anti-rust oil+Plastic films+Plastic bag+Carton+Pallet

-

Size:

-

08,08mm to 190,200mm ; Certification ISO/TS16949

-

Item model:

-

DU,DX,FB090,FB092,JDB,SF-1,SF-2,JCB,FU,FR,FZ,Roller ball transfer unit

-

Item model2:

-

DYB 500 JDB JF800 JF-800 SJ

-

Shipping info.:

-

By sea,By air,By express,all available.(DHL,FEDEX,UPS,TNT,TOLL,ect.)

-

Service:

-

Offer high-tech reliable products,And reply you at the first

Products Description

a novel lubricating bearing that combines the characteristics of metal bearing and oil-free bearing

Advantages and advantages of oil-free bearings

(1), smooth operation

Advantages of Oil-Free Bearings As we all know, all machinery must use some kind of bearing to run smoothly.

Oil-free bearing is a novel lubricating bearing that combines the characteristics of metal bearing and oil-free bearing.

(2) Excellent physical properties of oil-free bearings

It has the characteristics of high bearing capacity, impact resistance, high temperature resistance, strong self-lubricating ability, etc. It is especially suitable for heavy load, low speed, reciprocating or swinging and other occasions that are difficult to lubricate and form an oil film, and it is not afraid of water and other acid erosion. and scour. The majority of users generally reflect that the embedded bearing not only saves oil and energy, but also has a longer working life than ordinary sliding bearings.

Oil-free bearing The product is made of steel plate as the base, sintered spherical bronze powder in the middle layer, and a mixture of PTFE and lead rolled on the surface layer. It has the characteristics of small friction coefficient, wear resistance, corrosion resistance, oil-free self-lubrication and long service life. Using it can reduce costs, reduce noise, and prevent sticking and slipping.

several classifications of oil-free bearings

1. Metal-based solid inlaid oil-free bearings

A high-performance solid lubricant product of inlaid graphite and MoS2 composite solid lubricant on a metal substrate. It breaks through the limitation of general bearings relying on oil film lubrication. During use, the solid lubricant rubs against the shaft through frictional heat, forming an excellent condition for oil and powder to coexist and lubricate, which not only preserves the shaft protection from wear, but also makes the solid lubricating properties eternal. Moreover, its hardness is twice as high as that of ordinary copper sleeves, and its wear resistance is also twice as high. Using this product can reduce the cost, reduce the mechanical volume, avoid the phenomenon of shaft bite and reduce the mechanical noise and so on.

Products have been widely used in sliding parts of various machinery, such as printing presses, elevators, textile machines, tobacco machines, fitness equipment, hydraulic trucks, micro motors, solenoid valves, automobiles, motorcycles and household machinery, brackets, steel rolling equipment, Mining machinery, ships, gas turbines and other high temperature, high load, low speed and heavy load, metallurgical continuous casting machines, trains, etc.

2. Multi-layer composite oil-free bearing

It is a rolled sliding bearing. It has the characteristics of small friction coefficient, good wear resistance, good corrosion resistance and oil-free lubrication. The use of this product may also reduce costs, reduce mechanical volume, avoid shaft bite phenomenon and reduce mechanical noise.

Products have been widely used in sliding parts of various machinery, such as printing presses, elevators, textile machines, tobacco machines, fitness equipment, hydraulic trucks, micro motors, solenoid valves, automobiles, motorcycles and household machinery.

3. Metal-based inlaid solid self-lubricating bearings

It is a novel lubricating bearing that combines the characteristics of metal bearings and self-lubricating bearings. The metal base bears the load, and the specially formulated solid lubricating material plays the role of lubricating. It has the characteristics of high bearing capacity, impact resistance, high temperature resistance and strong self-lubricating ability.

Traditional oil-impregnated bearings have the advantages of low noise and self-lubrication, and oil-impregnated bearings have become the new favorite of computer CPU fan bearings, and the market demand is large; Applications in household appliances are also expanding.

4. Oil-free self-lubricating bearings

It is made of steel plate as the base, sintered spherical bronze powder in the middle layer, and a mixture of PTFE and lead rolled on the surface. It has the characteristics of small friction coefficient, wear resistance, corrosion resistance, oil-free self-lubrication and long service life. Using it can reduce costs, reduce noise, and prevent sticking and slipping.

Widely used in sliding parts of various machinery such as printing presses, textile machines, hydraulic trucks, tobacco machines, medicinal machinery, fitness equipment, micro motors, automobiles, motorcycles, etc.

5. Add boundary lubricating bearings

Acidic polyoxymethylene has high wear resistance. The bearing surface is regularly arranged with oil storage pit and must be filled with lubricating grease when assembling. It is especially suitable for high load and low speed rotating motion, rocking motion and frequent Under load, it is not easy to form fluid lubrication parts when opening and closing. Under boundary lubrication conditions, it can be used for a long time without oil and maintenance, and oil in the process can prolong the service life of the bearing.

Currently suitable for metallurgical machinery, mining machinery, water conservancy machinery, auto parts, construction machinery, agricultural machinery, etc.

Precautions for using oil-free self-lubricating bearings

1. It should be determined whether there are bumps, protrusions, etc. on the mating surface of the shaft center and shaft shell.

2. Whether there is dust or mold sand attached to the surface of the bearing shell.

3. Although it is a small bump, protrusion, etc., if it is, it should be removed with oil grindstone or fine sandpaper.

4. In order to avoid bumps during installation, a small amount of lubricating oil should be applied to the surface of the shaft and shaft housing. When installing the bearing on the shaft, force must be applied to the inner ring, and when installing the bearing to the bearing housing, force must be applied to the outer ring. When applying force to the bearing, be careful to make the force go down vertically and evenly, otherwise the bearing will be injured. For this reason, try to avoid partial hits as much as possible.

5. The hardness of the bearing may be reduced due to overheating, so it must not exceed 100 degrees. At this time, the bearing must be suspended by steel wire, or placed on the wire rod, on the support plate, not on the bottom of the groove. When the bearing reaches the desired temperature (below 100 degrees), it should be taken out of the groove immediately and put into the shaft quickly. The bearing will shrink as the temperature drops, and sometimes there will be a gap between the shoulder and the end face of the bearing. Therefore, A tool is required to compress the bearing in the axial direction.

6. The retainer and sealing plate of the oil-free bearing must not be forced. The installation method of using a hammer and a sleeve is a commonly used method, because it will damage the bearing, so do not hit it directly. Be sure to tap in with the sleeve in the middle as shown in the picture. The hammer should strike lightly. In the mechanical structure, when the inner and outer rings are tightly fitted, a backing plate should be used, so that the force can be applied to the inner and outer rings at the same time.

If only the inner ring is press-fitted, the force will be forced into the outer ring through the balls, thus causing scratches on the raceway surface. When installing a bearing with a large margin on the shaft, the method of heating the bearing to 80-90 degrees in clean oil and expanding the inner diameter is widely used.

Provide your draft, we can custom for you!

Please contact for more details!

Packing & Delivery

Packing

1,Print mark logo,

2,Anti-rust oil

3,Plastic films

4,Plastic bag or paper box

5,Carton+Pallet

2,Anti-rust oil

3,Plastic films

4,Plastic bag or paper box

5,Carton+Pallet

6,Port: shanghai,ningbo,shenzhen etc

Shipping:

1,Delivery Time : Usually 15-20 days.Depends on your quantity.

2,Generally, Free of standard size sample within 5 days.

Hot Searches