- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1850mm*450mm*550mm(L*W*H)

-

Weight:

-

523 KG

-

Marketing Type:

-

New Product 2024

-

Drilling angle:

-

(Tunnel) 0-360 degrees, surface 0-90 degrees

-

Drilling depth:

-

Drill pipe: Dia. 71 (NQ) mm -360m (horizontal), 420m (vertical)

-

Spindle speed:

-

290-900RPM (manual continuously variable transmission)

-

Spindle output torque:

-

296-1100 N.m (torque platform test)

-

Rated feeding force:

-

80 kn (torque platform test)

-

Feeding stroke:

-

750mm

-

Inner diameter of oil cylinder:

-

80mm

-

Chrome plated piston rod:

-

45m

-

Oil pump motor:

-

380V, 45KW

-

Motor:

-

1pc

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Glorytek

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1850mm*450mm*550mm(L*W*H)

-

Weight:

-

523 KG

-

Marketing Type:

-

New Product 2024

-

Drilling angle:

-

(Tunnel) 0-360 degrees, surface 0-90 degrees

-

Drilling depth:

-

Drill pipe: Dia. 71 (NQ) mm -360m (horizontal), 420m (vertical)

-

Spindle speed:

-

290-900RPM (manual continuously variable transmission)

-

Spindle output torque:

-

296-1100 N.m (torque platform test)

-

Rated feeding force:

-

80 kn (torque platform test)

-

Feeding stroke:

-

750mm

-

Inner diameter of oil cylinder:

-

80mm

-

Chrome plated piston rod:

-

45m

-

Oil pump motor:

-

380V, 45KW

-

Motor:

-

1pc

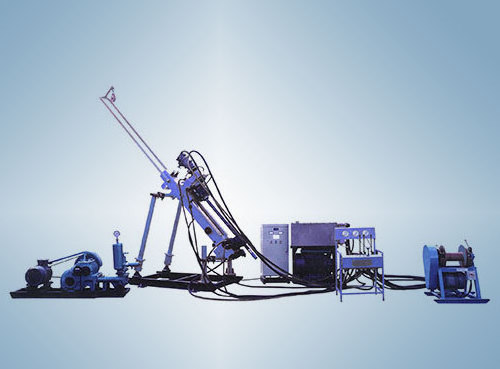

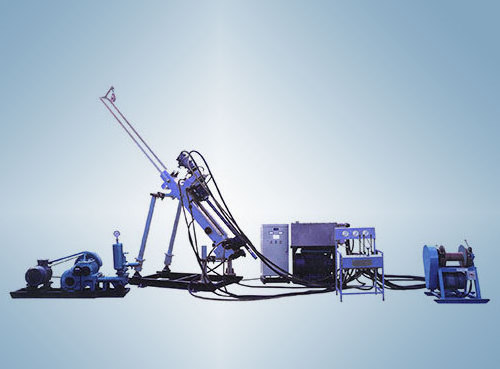

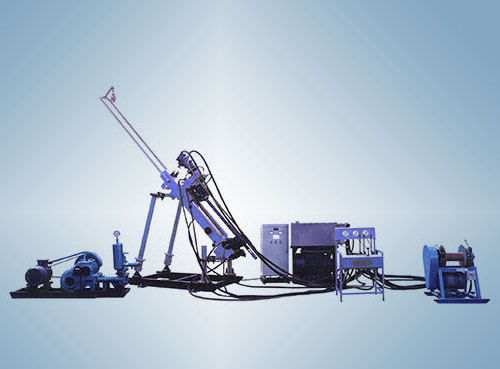

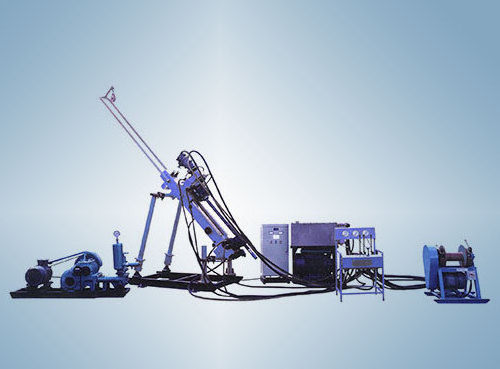

GLKD-500 Full Hydraulic Underground Core Drill Rig

Product Description

Main Specification of

GLKD-500 Full Hydraulic Underground Core Drill Rig

Drilling speed mainly refers to rock structure and driller technology. If the rock structure is good, the drilling speed is fast. The diamond bit is used to drill rock. The principle is soft grinding hard and hard grinding soft. The geological and rock structure of each region is different, and the drilling speed is also different. The drilling rig can drill 4.8m in an hour at the fastest and 1.3m in an hour at the slowest. (for example, rock hardness grade 14) the core recovery rate of the national standard is more than 75%. If the rock structure is good, the core recovery rate will reach more than 95%.

43mm drilling tools are suitable for mines with high ore content, such as mines with good rock structure (iron ore / lead-zinc) or less crushing.

The 60mm / 75mm hole is suitable for mines with relatively low content, such as (gold mine) and mines with poor rock structure and more fractures, or the coring diameter requiring geological reports and data needs to meet the technical standards.

|

GLKD-500 Full Hydraulic Underground Core Drilling Rig

|

|

|

|

Drilling angle:

|

(Tunnel) 0-360 degrees, surface 0-90 degrees

|

|

|

Drilling depth:

|

Drill pipe: Φ43mm- 500m

|

|

|

|

Drill pipe: Φ55.5(BQ)mm- 480m (horizontal), 500m (vertical)

|

|

|

|

Drill pipe: Φ71 (NQ) mm -360m (horizontal), 420m (vertical)

|

|

|

Spindle speed:

|

290-900RPM (manual continuously variable transmission)

|

|

|

Spindle output torque:

|

296-1100 N.m (torque platform test)

|

|

|

Rated feeding force:

|

80 kn (torque platform test)

|

|

|

Feeding stroke

|

750mm

|

|

|

Inner diameter of oil cylinder

|

80mm

|

|

|

Chrome plated piston rod

|

45m

|

|

|

Oil pump motor:

|

380V, 45KW

|

|

|

Motor

|

1pc

|

|

|

Hydraulic system:

|

The maximum volume of the oil tank is 150 L, 46# anti-wear hydraulic oil, and the system pressure is 160 bar

|

|

|

Drill Rig Weight:

|

523kg (decomposable)

|

|

|

Dimension:

|

1850mm*450mm*550mm(L*W*H)

|

|

|

Console weight:

|

60kg

|

|

|

Dimension:

|

610mm*530mm* 1050mm

|

|

|

Power unit weight:

|

550kg (decomposable)

|

|

|

Dimension:

|

1280mm*800mm*1200mm

|

|

|

Drilling tool selection:

|

1. Drill pipe Φ 43mm × 1500mm

|

|

|

|

Double tube double acting core tube Φ 45mm* 1500mm

|

|

|

|

Diamond bit Φ 46.5mm,reaming shell Φ 47mm

|

|

|

|

Core removal Φ 30mm

|

|

|

|

2. wireline core drill pipe φ 55.5(BQ)*1500mm

|

|

|

|

wireline coring double tube single acting core tube φ58 × 1500mm

|

|

|

|

diamond bit φ 60 (BQ) ,reaming shell φ 60.8(BQ)

|

|

|

|

Core removal φ 36mm

|

|

|

|

3. wireline core drill pipe φ 71(NQ)*1500mm

|

|

|

|

wireline coring double tube single acting core tube φ 73(NQ)*1500mm

|

|

|

|

diamond bit φ 75 (NQ), reaming shell φ 75.5(NQ)

|

|

|

|

Core removal φ 48mm

|

|

Pictures of

GLKD-500 Full Hydraulic Underground Core Drill Rig

Features:

1. Small size, light weight and easy installation.

2. It consists of three major parts, the main machine, the pump station, and the operation console.

3. It can be put into production in the original transportation and exploration roadway, which plays a role in protecting the overall structure of the mine. It can also be used for surface 0-90 degree drilling.

4.The drilling rig is arranged flexibly, and the drill pipe can be twisted and unloaded mechanized, which reduces the labor intensity of workers and improves work efficiency.

5.The drilling rig adopts box feed frame, the gripper is tightened, the power head rotates for drilling, and the oil cylinder

pulls the drilling tool, which can save the heavy drilling tower.

5.The drilling rig adopts box feed frame, the gripper is tightened, the power head rotates for drilling, and the oil cylinder

pulls the drilling tool, which can save the heavy drilling tower.

6.With linkage function, centralized control through the operation console, simple and safe, and stepless speed regulation.

7.Hollow shaft design, the length of the drill pipe is not limited by the given stroke of the drill. It can drill at any inclination angle of 360°.

8.Good disintegration, convenient relocation and transportation. φ43-φ55.5-φ71 drill pipes can be used in the same machine, and the replacement only takes 15 minutes.

9.Centralized console for oil pump, water pump and power supply.

10.The pull-out column is suitable for roadways with different heights. There are two kinds of columns: 1.8m-3m and 3m-4.5m.

11.The drill pipe is made of China advanced materials, processed with high precision and quenched to increase the service life of the drill pipe.

12.The 60 mm hole and 75 mm hole can obtain 360 degree wireline coring, the working efficiency is nearly twice that of ordinary double pipe, and the manual strength is reduced.

13.The imported oil gauge line can bear high and soft pressure, reduce the impulse of high-pressure oil pulse, make the

pointer of hydraulic oil gauge more stable, and timely find the changes of stratum and rock in the hole.

pointer of hydraulic oil gauge more stable, and timely find the changes of stratum and rock in the hole.

14.Special customized oil temperature cooler and copper pipe in oil tank, fast cooling of high-pressure oil and low-temperature use, which can protect the service life of motor, oil pump and rubber seal.

15.The drill rig can be equipped with crawler. 16.Two people in a shift can operate skillfully in 2-5 days.

Packing and Transport

Packing: Seaworthy Packing

Delivery: about 20 days after your down payment.

Hot Searches