- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Oil Drilling

-

Key words:

-

Drill Bit

-

Size:

-

M/S316*F

-

Color:

-

Golden

-

Certification:

-

API 7-1

-

Standard:

-

ISO 9001

-

Advantage:

-

High-efficiency

-

Transportation:

-

By Sea

Quick Details

-

Weight (KG):

-

60

-

Place of Origin:

-

Shandong, China

-

Product name:

-

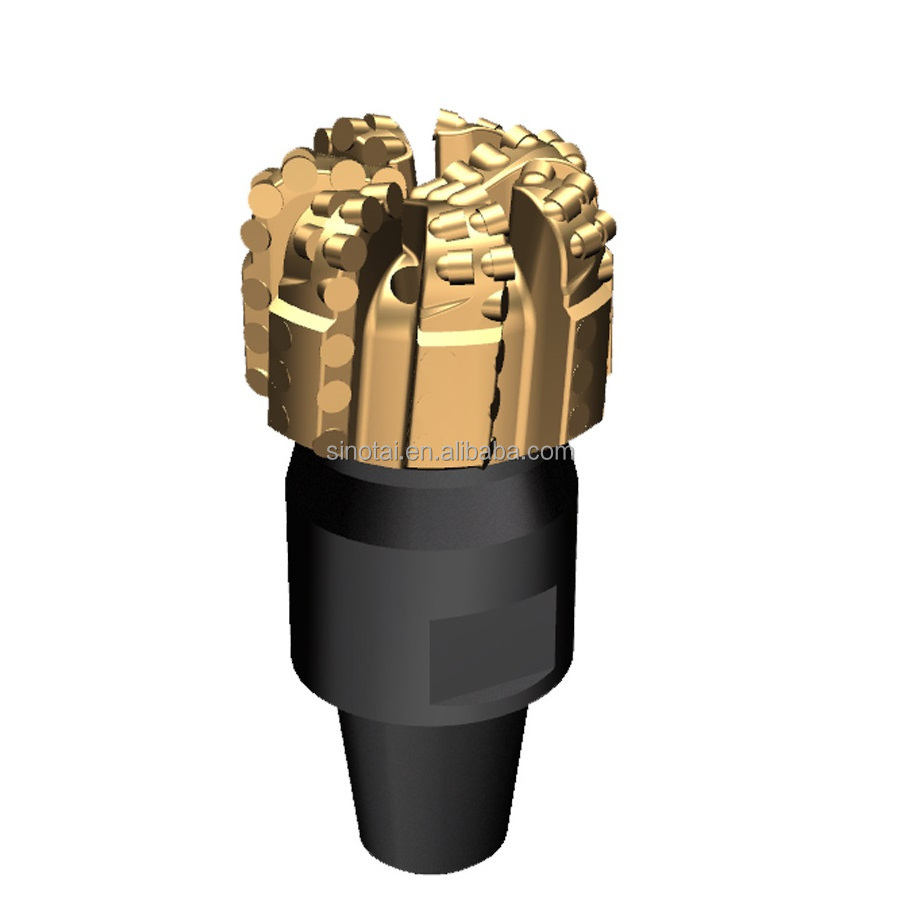

PDC BITS

-

Application:

-

Oil Drilling

-

Key words:

-

Drill Bit

-

Size:

-

M/S316*F

-

Color:

-

Golden

-

Certification:

-

API 7-1

-

Standard:

-

ISO 9001

-

Advantage:

-

High-efficiency

-

Transportation:

-

By Sea

Product Description

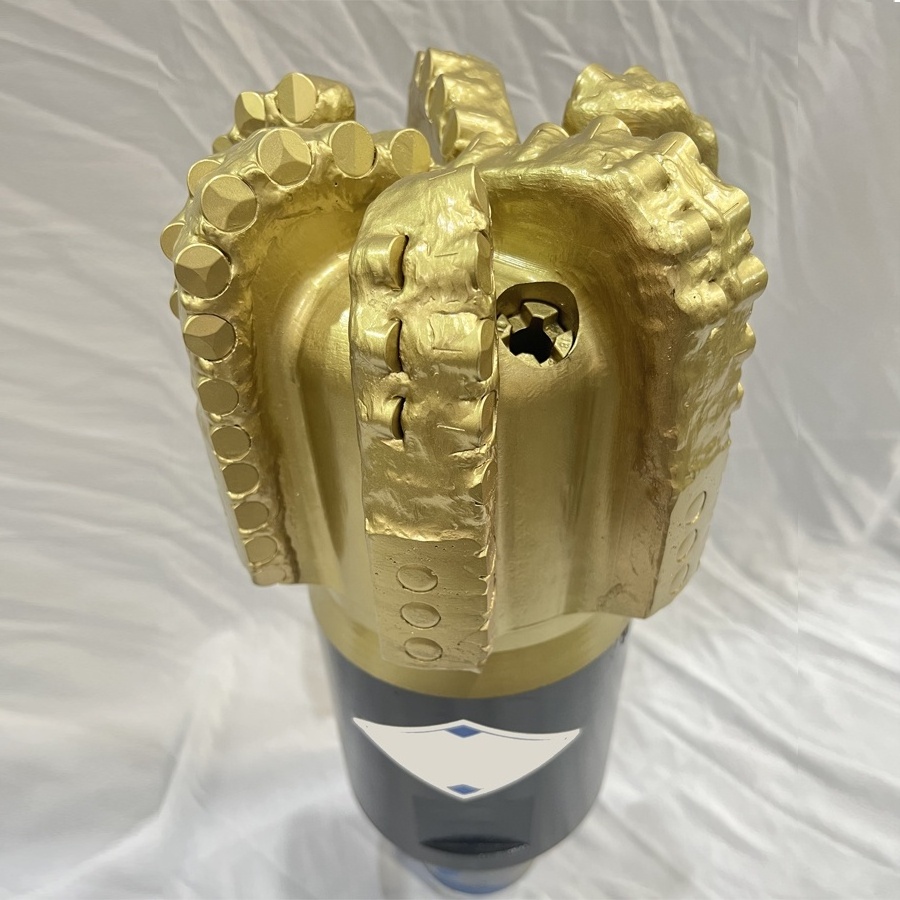

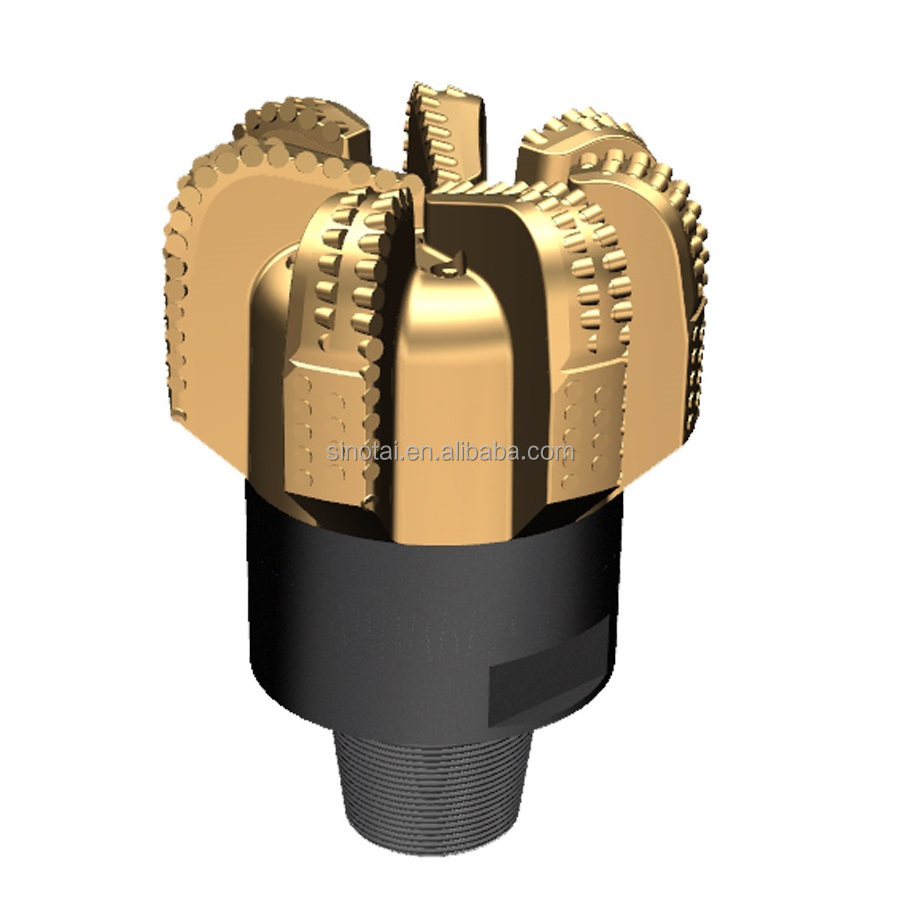

PDC BITS

H Hard

Series

Adopting IDS equidistant design models

UsingC3, P3/P4, G2/G3 crown types to strengthen the internal cone and shoulder tooth density, preventing wellbore contraction

Using T4, T5 high-performance cutters to enhance wear resistance

Applying H2 hydraulic structure design to improve tooth surface cooling effect

Implementing multi-blade design technology

Implementing B13, BA auxiliary design to improve drill stability and shoulder wear resistance.

Specification

|

Formation

|

IADC

|

Lithology

|

Bits Selection

|

|

Medium to Hard

|

M323/S323

M333/S333 |

Sandstone, Dolomite, Limestone

|

M/S516*H, /S616*H M/S513*H, M/S613*H

|

|

Hard

|

M423/S423

M433/S433 |

Tuff, Granite, Siltstone, Dolomite

|

M/S716*H, /S613*H M/S713*H, M/S813*H

|

Certificates

Packing & Delivery

Workers load the finished drill bits into special wooden boxes and wait for them to be loaded and shipped

Hot Searches