- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4800x2100x5250 mm

-

Weight:

-

37000 KG

-

Place of Origin:

-

Mexico

-

Voltage:

-

Customized

-

Power:

-

37Kw

-

Product Type:

-

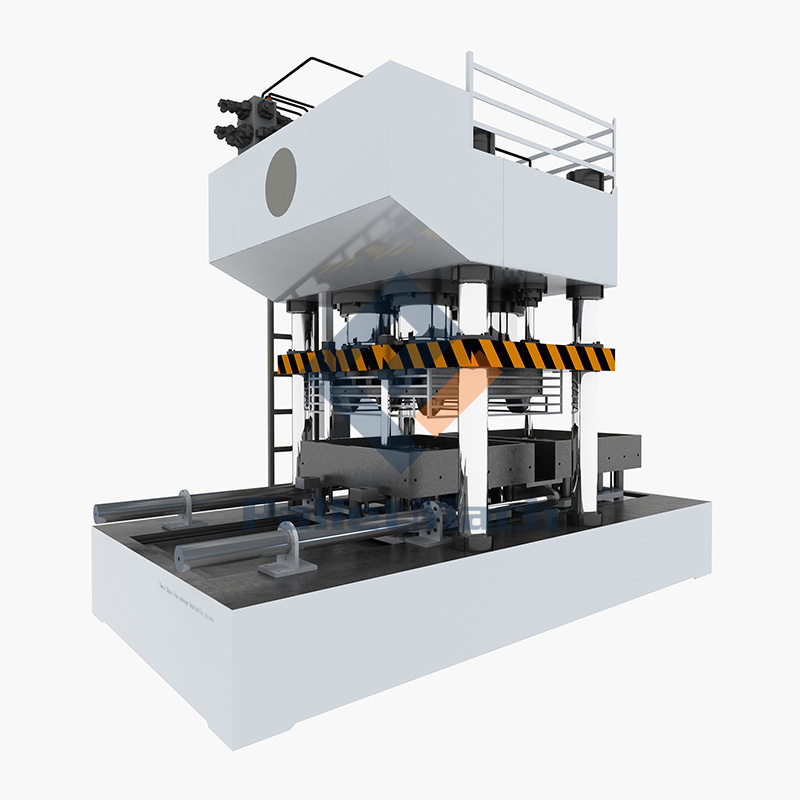

Automatic Wood Pallet Machine

-

Machine Type:

-

Wood Pallet Machine

-

Core Components:

-

Motor, PLC, Pressure vessel

-

Capacity:

-

324 pcs/24h

-

Mold numbe:

-

one upper mold and one lower mold

-

After sale service:

-

24 hours online service

-

Raw material:

-

Waste wood, dead branches, scraps, waste boards

-

Application:

-

Logistics, transportation, warehousing, etc.

-

Power Source:

-

Hydraulic

-

Color:

-

Costomized

-

Name:

-

hydraulic pallet press machine

Quick Details

-

Machinery Capacity:

-

432 pcs/24h

-

Brand Name:

-

PalletMach

-

Year:

-

2yers

-

Dimension(L*W*H):

-

4800x2100x5250 mm

-

Weight:

-

37000 KG

-

Place of Origin:

-

Mexico

-

Voltage:

-

Customized

-

Power:

-

37Kw

-

Product Type:

-

Automatic Wood Pallet Machine

-

Machine Type:

-

Wood Pallet Machine

-

Core Components:

-

Motor, PLC, Pressure vessel

-

Capacity:

-

324 pcs/24h

-

Mold numbe:

-

one upper mold and one lower mold

-

After sale service:

-

24 hours online service

-

Raw material:

-

Waste wood, dead branches, scraps, waste boards

-

Application:

-

Logistics, transportation, warehousing, etc.

-

Power Source:

-

Hydraulic

-

Color:

-

Costomized

-

Name:

-

hydraulic pallet press machine

Products Description

Hot Press Wood Chips Sawdust Shaving Pallet Molding Machine For India

Compressed Pallet Making Machine

Press pallet machine is a new type of pallet machine that produces compressed pallets with raw materials of waste wood, wood scrap, waste pallets, bamboo, straws, sawdust, coconut husks and other materials containing wood fiber. Press pallet machine also can be used to produce molded plastic pallet with recycling plastic wastes.

Press wood pallet, full name is the plant fiber molded industrial plane pallet.

Normally wood chips and plant straws are the raw materials. We tested different materials and expanded range to wood waste board, sawdust and shavings, waste pallets, bagasse, wheat straw and cotton straw, waste furniture etc.

Details Images

Product Paramenters

|

Model

|

PM-1000

|

PM-1000D

|

|

|

Voltage

|

Customized

|

|

|

|

Capacity

|

324 pcs/day (24 hours)

|

432 pieces/day (24hours)

|

|

|

Power

|

18.5 kW

|

22 kW

|

|

|

Hydraulic cylinder diameter

|

350 mm

|

|

|

|

Hydraulic cylinder quantity

|

4 pieces

|

|

|

|

Pressure

|

0-1000 t (adjustable)

|

0-1200 tons (adjustable)

|

|

|

Shaping cycle

|

160 seconds

|

|

|

|

Weight

|

22 tons

|

37 tons

|

|

|

Dimension

|

2000*1400*3500 mm

|

4800*2100*5250 mm

|

|

Production Process

The main equipment of this production line consists of a series of chippers, crushers, dryers, glue mixers, hot presses, etc. The raw materials are chipped and crushed into wood chips of a certain length, and then enter the dryer to dry the excess moisture. Add glue to the dried wood chips and stir them thoroughly. The mixed material can be filled into the mold and hot-pressed. After hot-pressing, the molded molded tray can be taken out.

Advantages of molded pallet production line

1. Save raw material costs. This production line can use various waste wood, leftover materials, building templates, branches and other traditional wood to produce molded pallets, which can significantly reduce the raw material costs of pallets;

2. Fully automatic production. The production line can be equipped with a fully automatic production solution. Only one or two workers can complete the daily operations of the entire production line;

3. High production efficiency, pallet production adopts automatic spreading, automatic hot pressing, automatic ejection and palletizing devices;

4. Wide application. If you need to produce pallets of other patterns, you only need to simply change the mold;

5. The pallet is of high quality and waterproof;

6. Environmentally friendly and energy-saving, after the produced pallets are damaged, they can be recycled repeatedly to make new pallets;

Hot Searches