- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

P830

-

Product name:

-

Powder nitrile rubber (PNBR)

-

Model:

-

P830

-

Appearance:

-

powder

-

Color:

-

white

-

Mooney Viscosity(ML1+4,100 ):

-

150±10

-

Packing:

-

20kg/box

-

Isolating agent%:

-

6-8

-

Advantage:

-

Oil resistant, heat and abrasion resistant

-

Appliaction:

-

Disc brake pads, drum brake pads, etc

-

Sample:

-

free

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

jiansheng

-

Model Number:

-

P830

-

Product name:

-

Powder nitrile rubber (PNBR)

-

Model:

-

P830

-

Appearance:

-

powder

-

Color:

-

white

-

Mooney Viscosity(ML1+4,100 ):

-

150±10

-

Packing:

-

20kg/box

-

Isolating agent%:

-

6-8

-

Advantage:

-

Oil resistant, heat and abrasion resistant

-

Appliaction:

-

Disc brake pads, drum brake pads, etc

-

Sample:

-

free

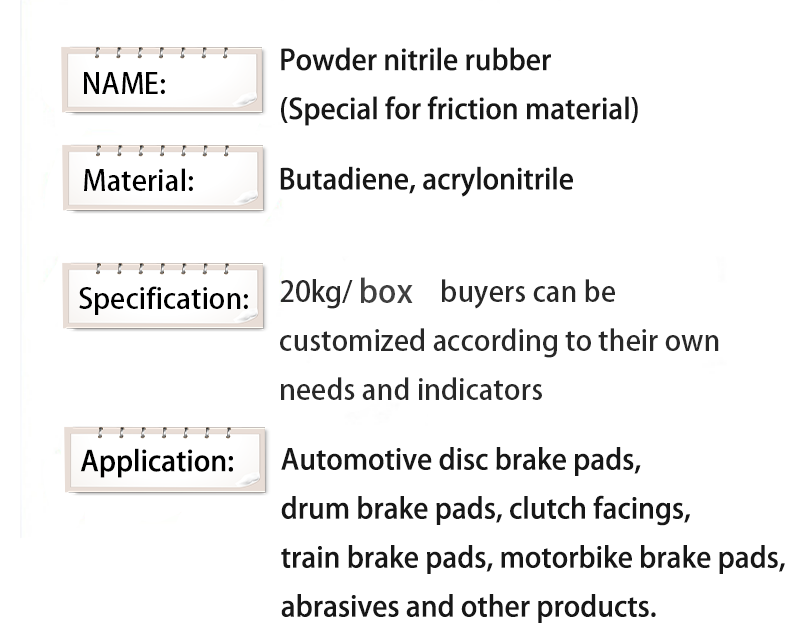

Products Description

Product Description

:

This powdered nitrile is specially designed for friction materials.

Powdered NBR has a good adhesive effect and bridges with phenolic resins to increase the bonding ability of friction materials and improve the flexibility of friction materials.

This product is a custom product, you can consult customer service before purchase, the final price is subject to processing custom claims!

package standard

25KG/BOX, or customized by requested

Product parameters

|

Model

|

ACN conten %

|

Mooney viscosity

ML(1+4)100℃

|

Mesh

|

Application

|

|

P830

|

30±2

|

150±50

|

40 mesh

sieving rate ≥98%

|

Half cross-linked PNBR. It is suitable for the auxiliary products of the host plant , with good stability performance, small

addition ratio, better combination with phenolic resin, improve the brittleness of phenolic resin, increase the flexibility of the

product, improve the friction coefficient, improve the impact strength of the product, reduce the hardness of the product, reduce

the noise, improve the braking comfort, and have obvious effect on heat recession.

|

|

P8302

|

30±2

|

130±50

|

40 mesh

sieving rate ≥98% |

Half cross-linked PNBR. Applied to the field of friction materials, it is better compatible with phenolic resins, improves the

coefficient of friction, increases impact strength, reduces hardness, reduces noise and improves the comfort of braking. |

|

P320

|

25±2

|

/

|

120 mesh

sieving rate ≥98% |

Fully cross-linked PNBR. Improves the brittleness of phenolic resins, increases product flexibility, reduces the hardness of

products, reduces product noise and improves product braking comfort. |

|

ZC-835

|

30±2

|

160±10

|

40 mesh

sieving rate ≥98% |

Half cross-linked PNBR. Mainly applied to the aftermarket for brake pads, this product is better compatible with phenolic resins,

improves the coefficient of friction, increases the impact strength of the product, reduces hardness and has a significant improvement on low temperature noise reduction. It has good oil resistance, high temperature resistance and improves braking comfort. |

|

JS-835

|

30±2

|

160±10

|

40 mesh

sieving rate ≥98% |

Half cross-linked PNBR. Applied to the field of friction materials, it has better compatibility with phenolic resins, improves

cracking problems in brake pad drilling, has good oil and high temperature resistance, and improves braking comfort. |

|

JS-833

|

26±2

|

70±10

|

40 mesh

sieving rate ≥98% |

Non-cross-linked PNBR. It can fully combine with resin, improve the bonding performance of products, improve the brittleness of

phenolic resin, increase the flexibility of products, reduce the hardness of products, reduce the noise of products and improve the comfort of products braking. |

|

JS-502

|

/

|

90±10

|

40 mesh

sieving rate ≥98% |

Half cross-linked PSBR. Applied to various brake pad fields, the product has excellent adhesion in the manufacturing process, good

fluidity and can improve the dispersion of raw materials. Good resistance to low temperatures and high wear resistance. Low noise and good comfort in the braking process. |

Product advantages

Performance advantages

1.Improve the heat resistance, oil resistance, wear resistance and low temperature resistance of the products. 2.Good dispersion in the blending of raw materials, reducing the friction rate of the product.

3.During the use process, reduce the hardness of the product, improve the braking noise of the product, and improve the comfort of the braking process.

4.The fluidity and brittleness of phenolic resin has a significant improvement, the combination of the two has a good complementary effect, improving the stability of the friction coefficient. The cracking of the product and drilling chipping has a significant improvement effect.

5.Good resistance to low temperature flexing, compression permanent deformation, ageing resistance, improve the impact resistance of the product.

Why Choose Us

FAQ

About placing an order

If you need to customize, please consult customer service before placing your order, we will help you answer production questions.

About the manufacturer

The company's production cycle is short and the quality of the goods is guaranteed.

About the quality

We support video and offline factory inspection, we provide samples for you to check.

About the samples

We offer free samples, but you will need to pay for shipping.

About the pictures

All products images are taken in real life.

About after-sales service

We will provide a complete after-sales service and a full online service.

About delivery

Please contact our customer service for specific logistics.

Hot Searches