●

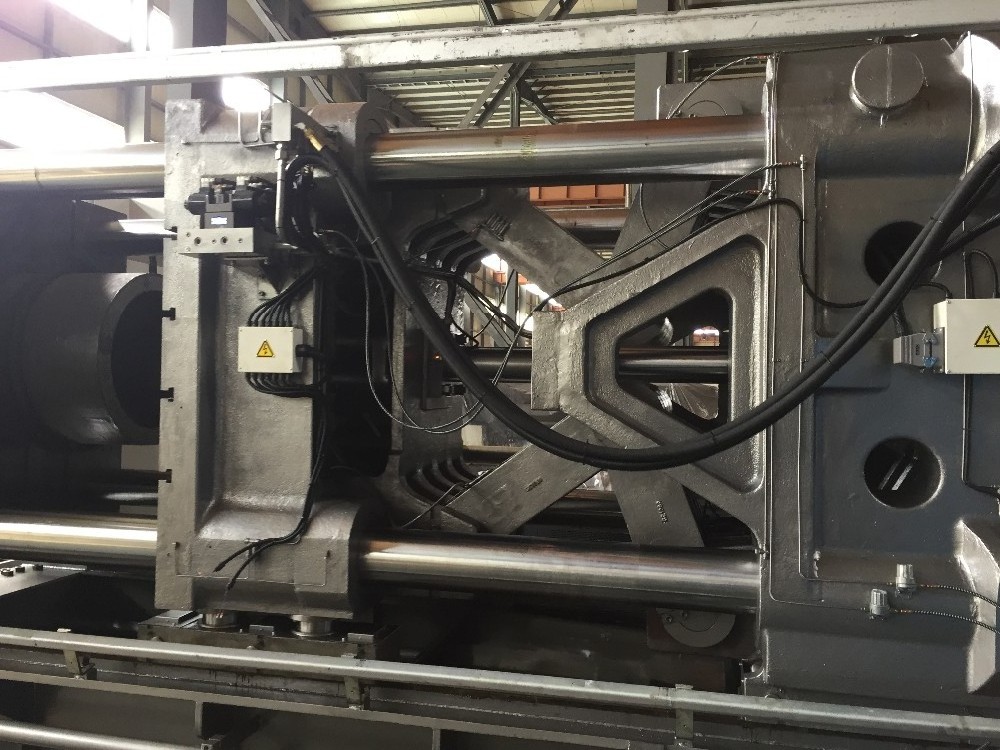

Superior mould platen to ensure no out of shape if high-pressure clamping.

●

Hard chrome plated high tensile strength tie bars made of superior alloy.

●

Wear-resistant guide for moving platen.

●

Transducer control clamping stroke.

●

Many step control for speed and pressure of clamping and opening.

●

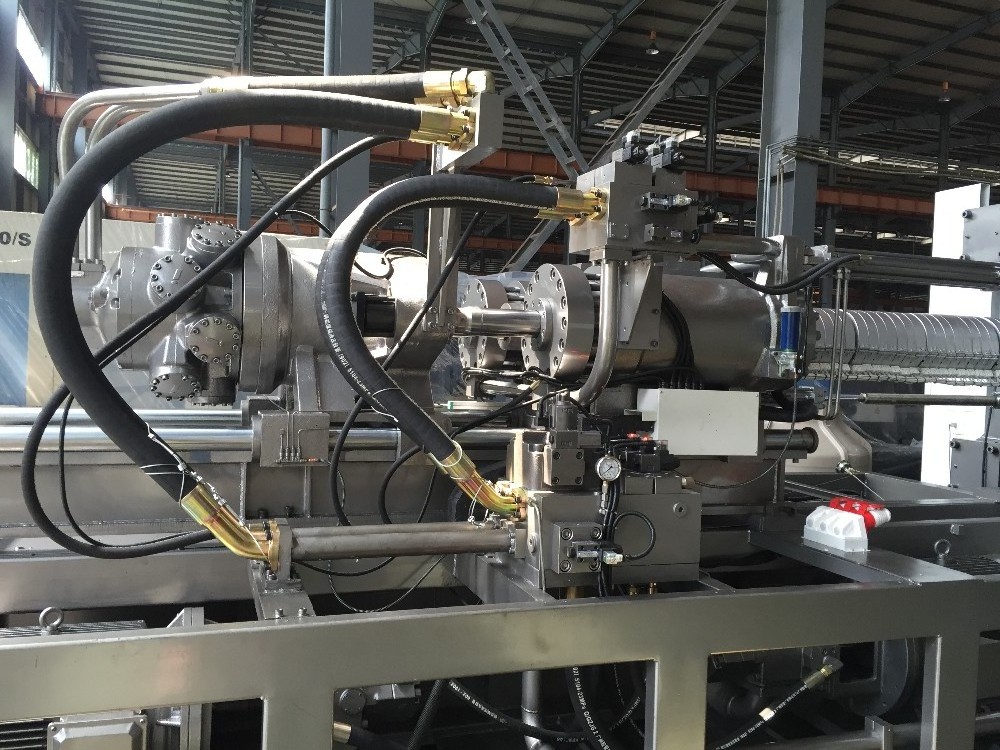

Eiection device offer dwell,single,more, vibration function.

●

Low pressure mould protection function.

●

Hydraulic mould height adjustment with roungh and fine operation.

●

Mechanical and electrical dual safety interlock.

●Automatic centralized lubrication system with far pressure detector.