- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Briquette Extruder Machine

-

Keyword:

-

Charcoal Dust Briquette Machine

-

Name:

-

Charcoal Briquette Press Machine

-

Usage:

-

Making Charcoal Coal Briquette

-

Package:

-

Wooden Case

-

After-sales Service Provided:

-

1 Year

-

Advantage:

-

High Efficiency Low Energy

-

Function:

-

Press Biomass Material

-

Suitable material:

-

Hard Wood Sawdust Rice Husk

Quick Details

-

Place of Origin:

-

Henan, China

-

Weight:

-

800 KG

-

Raw material:

-

Sawdust

-

Product name:

-

Briquette Extruder Machine

-

Keyword:

-

Charcoal Dust Briquette Machine

-

Name:

-

Charcoal Briquette Press Machine

-

Usage:

-

Making Charcoal Coal Briquette

-

Package:

-

Wooden Case

-

After-sales Service Provided:

-

1 Year

-

Advantage:

-

High Efficiency Low Energy

-

Function:

-

Press Biomass Material

-

Suitable material:

-

Hard Wood Sawdust Rice Husk

Fully Automatic Briquette Charcoal Machine sawdust briquette wood Rice Husk Charcoal Making Machine

Product Description:

The charcoal machine is the main equipment that uses wood chips, sawdust wood, rice husks, peanut shells, plant straws and other carbon-containing wood materials (without any additives) to make rod-shaped solid fuels under high pressure and high temperature conditions. One of the important supporting equipment. With its unique performance advantages, sawdust charcoal machines are more and more widely used in industry, agriculture, chemical industry, metallurgy, heating, barbecue and other fields.

|

Equipment model:

|

ZBJ-50A

|

Equipment weight:

|

800kg

|

|

Motor power:

|

18.5kw (380V 50HZ)

|

Out rod diameter:

|

φ 48

|

|

Production capacity:

|

240-280kg/h

|

Dimensions:

|

1700×750×1350(mm)

|

Rod making machine features:

1. The rod making speed is fast, the density of the finished product is higher, the forming efficiency is high, no cracking, and the temperature is easy to adjust. The screw propeller of the rod making machine adopts special wear-resistant materials, and the designed automatic control electric heating device can adjust the material randomly. High dry humidity, stable discharging and forming, improve work efficiency.

2. The rod making machine is suitable for pressing and molding of various biomass raw materials, and has the characteristics of reasonable design, reliable manufacturing quality, simple structure, convenient operation, small size, small footprint, labor saving and power saving.

3. The structure of the forming cylinder is improved, the friction between the machine and the raw material is reduced, and the density of the mandrel is increased.

Product details

Alloy forming cylinder

Made of high-chromium alloy material, high temperature and wear resistance, stable and reliable quality.

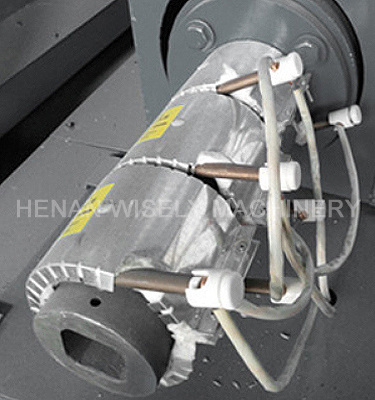

Heating ring

The whole machine is carefully assembled, the heating part is equipped with an insulating porcelain sleeve, and the outer ring is shielded to avoid leakage and improve safety.

Control panel

One-key operation, automatic heating control, simple and convenient production, and can be easily operated without professionals.

Show results

Scope of application

The product can be applied to various materials such as wood, sawdust, branches, straw, corncob, nut shell, peanut shell, etc. It can be made into sticks after crushing.

Our service:

Before-sale services

1. 24 hours online, Your inquiry will be reply quickly.

2. Help you choose the most suitable machine

3. Introduce details of the machine for you with pictures or video.

Sales service

1. Customized machine according to your request.

2. Test and inspect every machine with strict quality control.

3.Packing with standard export wooden box after you confirm the machine

After-sales service

1. Offer the professional engineer help you to use the machine.

2. Offer technical support and professional engineer help you solve problems while using it.

3. Quality guarantee for two years. Free repair for quality problem during these years.

1. 24 hours online, Your inquiry will be reply quickly.

2. Help you choose the most suitable machine

3. Introduce details of the machine for you with pictures or video.

Sales service

1. Customized machine according to your request.

2. Test and inspect every machine with strict quality control.

3.Packing with standard export wooden box after you confirm the machine

After-sales service

1. Offer the professional engineer help you to use the machine.

2. Offer technical support and professional engineer help you solve problems while using it.

3. Quality guarantee for two years. Free repair for quality problem during these years.

FAQ:

Q:1.Are you a factory or a trading company?

A:We are a factory mainly produces the machinery for 12 years.We have our own professional research team to develop products.using

"Self-produced

Self-marketing" business model, reducing the cost of intermediate links.

Q:2.Where is your factory located ? How can I visit there?

A:Our factory is located in Kaifeng city ,Henan province ,China.1 hour drive from nearest zhengzhou xinzheng airport.

Q:3.How long is your delivery time?

A:All machines can be 10 working day after receive the deposit.

Q:4.What should I do if there is some trouble while using?

A:We will supply English manual book and take a video to show how to resolve the problems or dispatch our engineer to your

factory.

Q:5.Can we buy one sample?

A:Yes, one sample order is welcome. However, we need to add sample fee to the price and will return it back to you after receiving

your large order in future.

Q: 6.How do you control your quality?

A:To guarantee high quality and efficient management, our whole manufacturing processes are under a very serious and strict

system, and we have passed ISO9001 quality management system certificate. All of our products are 100% inspected before shipment.

Q:7.What’s the Payment term?

A:30% deposit, 70 % before delivery or Trade Assurance.L/C,T/T,PayPal,and so on.

A:We are a factory mainly produces the machinery for 12 years.We have our own professional research team to develop products.using

"Self-produced

Self-marketing" business model, reducing the cost of intermediate links.

Q:2.Where is your factory located ? How can I visit there?

A:Our factory is located in Kaifeng city ,Henan province ,China.1 hour drive from nearest zhengzhou xinzheng airport.

Q:3.How long is your delivery time?

A:All machines can be 10 working day after receive the deposit.

Q:4.What should I do if there is some trouble while using?

A:We will supply English manual book and take a video to show how to resolve the problems or dispatch our engineer to your

factory.

Q:5.Can we buy one sample?

A:Yes, one sample order is welcome. However, we need to add sample fee to the price and will return it back to you after receiving

your large order in future.

Q: 6.How do you control your quality?

A:To guarantee high quality and efficient management, our whole manufacturing processes are under a very serious and strict

system, and we have passed ISO9001 quality management system certificate. All of our products are 100% inspected before shipment.

Q:7.What’s the Payment term?

A:30% deposit, 70 % before delivery or Trade Assurance.L/C,T/T,PayPal,and so on.

Hot Searches