- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HX

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Luoyang Hongxin

-

Diameter:

-

100-4000mm

-

Application Range:

-

Suitable for all kinds of machinery

-

Processing Type:

-

forging/casting

-

Certificate:

-

ISO 9001:2008

-

After-sales Service Provided::

-

Proving overseas service from engineers

-

Process:

-

Forging+machining+heating Treatment

-

Surface Treatment:

-

polishing

-

Keyword:

-

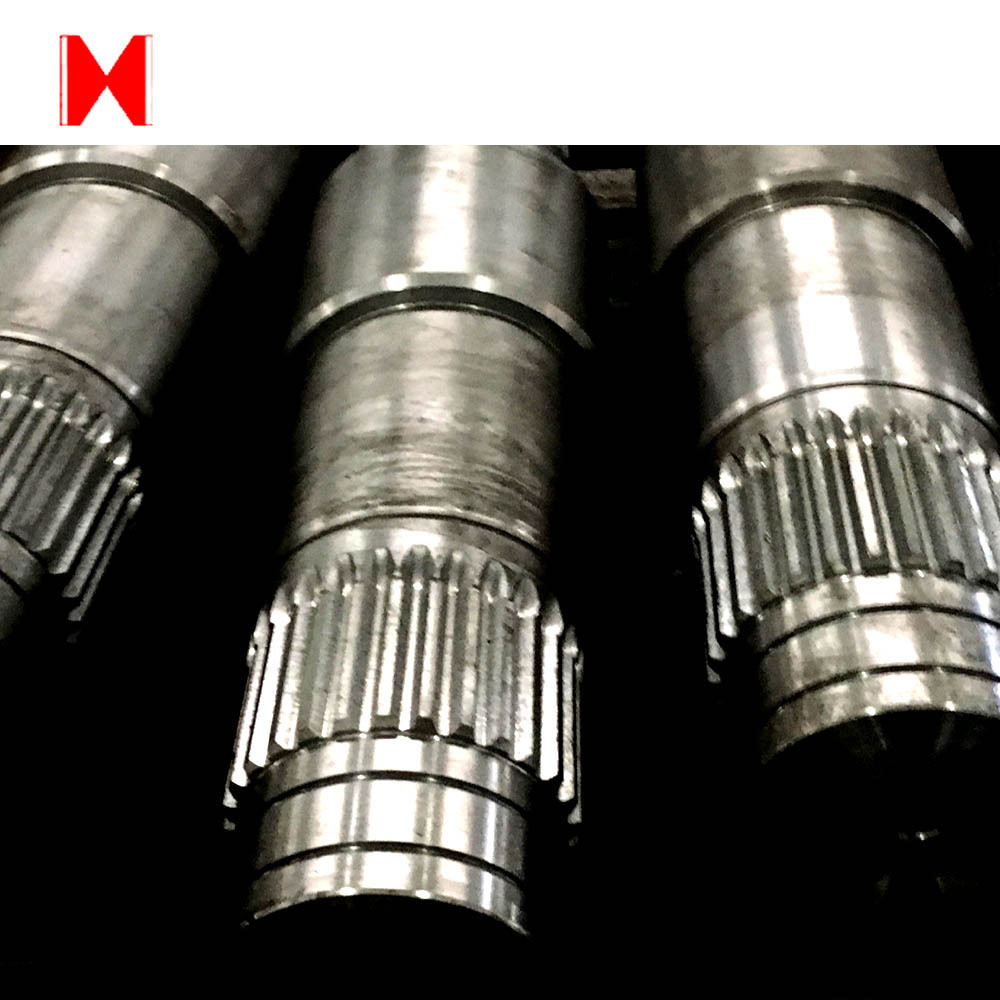

Main Shaft/Output Shaft/Input eccentric shaft

-

Heat treatment:

-

Quenching Hardening

Quick Details

-

Core Components:

-

shaft

-

Material:

-

aisi4130, aisi4130

-

Torque Capacity:

-

2000N.M

-

Model Number:

-

HX

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Luoyang Hongxin

-

Diameter:

-

100-4000mm

-

Application Range:

-

Suitable for all kinds of machinery

-

Processing Type:

-

forging/casting

-

Certificate:

-

ISO 9001:2008

-

After-sales Service Provided::

-

Proving overseas service from engineers

-

Process:

-

Forging+machining+heating Treatment

-

Surface Treatment:

-

polishing

-

Keyword:

-

Main Shaft/Output Shaft/Input eccentric shaft

-

Heat treatment:

-

Quenching Hardening

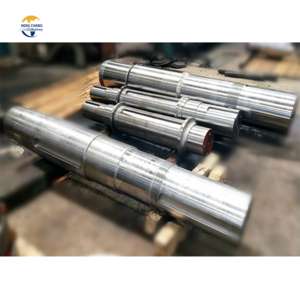

Products Description

|

Product Name

|

Forging shaft for sales

|

Length

|

0.2m-8m,can be designed

|

|

Hardness(HRC/HB260-275)

|

50-62

|

MOQ

|

1 Piece

|

|

Place of Origin

|

Luoyang,Henan

|

OEM Service

|

Accepted

|

|

Material

|

Stainless Steel,42CrMn,35CrMn,45S

|

Process

|

Forging

|

|

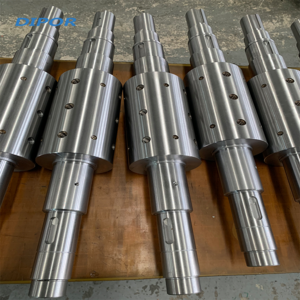

Application Range

|

Suitable for speed reducer,ball mill,mine hoist,stone crusher

|

Test

|

UT & MT

|

|

Inspection

|

Professional Quality Controller

|

After-sales Service Provided |

Proving overseas service from engineers

|

|

Certificate

|

ISO 9001:2000,DIN,ASME,ANSI

|

Machining Flow

|

Normalize-Rough Turning-Tempering-Precision Process-Quality Control-Finished

|

|

Export Areas

|

Russia, Southeast Asia, India,South Africa, Australia

|

Lead Period

|

30-45 days after receipt of 30% advanced payment

|

Brief Introduction and Application gear shaft

1.Applied to various kinds of machinery devices forged shaft

2.Forging shaft with high quality

3.Low price

4.Direct sale from factory

1.Applied to various kinds of machinery devices forged shaft

2.Forging shaft with high quality

3.Low price

4.Direct sale from factory

Processing

|

Our cooperation manufacture forging equipment

|

1000T Quick Forging Presses, 3150T Free Forging Presses, 5T Free Forging Hammers, 8400T and 18500T Hydro-presses (used for

large-scale forging orders) |

|

|

||

|

Main Machining Equipment

|

Fixed-Beam Gantry Type Boring and Milling Machining Centers (working size: 2.8m*6m), 6.3m Vertical Lathes, 1.8m*8m Horizontal

Lathes and Deep Drilling and Boring Mills (especially suitable for internal hole and side hole rough machining). |

|

|

||

|

Main Heat Treatment Equipment

|

5.5 x 2.0M Pit quenching and tempering furnaces, 1.6 x 8.0M Pit carburizing quenching and tempering furnaces, 3.5 x 4.0M Pit

quenching and tempering furnaces and 2.0 x 2M Pit carburizing quenching and tempering furnaces |

|

|

||

Inspection

*

QA DOC: Chemical Composition Report, Mechanical Properties Report, UT Report, Heat Treatment Report, Dimensions Check

Report.steel transmission shaft CNCShaft

* The data on chemical composition report and mechanical properties report are approved by third party, Luoyang Ship Material

Research Institute, CSIC.

* UT test: 100% ultrasonic test according to EN10228-3, SA388, Sep 1921 C/c etc.CNC shaft

* Heat Treatment Report: provide original copy of heat treatment curve/time table.CNCforgedshaft

* Steel Ingot: EAF-LF-VD/ESR. Material Certificate according to En10204-3.1 is requested from ingot supplier.

Report.steel transmission shaft CNCShaft

* The data on chemical composition report and mechanical properties report are approved by third party, Luoyang Ship Material

Research Institute, CSIC.

* UT test: 100% ultrasonic test according to EN10228-3, SA388, Sep 1921 C/c etc.CNC shaft

* Heat Treatment Report: provide original copy of heat treatment curve/time table.CNCforgedshaft

* Steel Ingot: EAF-LF-VD/ESR. Material Certificate according to En10204-3.1 is requested from ingot supplier.

our services

1>.Pre-sale services: enthusiasm transmission shaft

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

transmission shaft

2>.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept

together with you. transmission shaft

3>.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

Supplying technique, building design, instruction, installation and debugging for free.

4>.We provide one-year warranty to make sure your machine runs consistently

We always offering lifelong services and provide spare parts for a long term,and repair main parts under right using for free in two years.

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

transmission shaft

2>.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept

together with you. transmission shaft

3>.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

Supplying technique, building design, instruction, installation and debugging for free.

4>.We provide one-year warranty to make sure your machine runs consistently

We always offering lifelong services and provide spare parts for a long term,and repair main parts under right using for free in two years.

packaging&shipping

Packaging DetailsWooden cases, shipping containers or according to customers' demand.suitable for long transportation Port Tianjin,Shanghai, Qingdao, etc.

|

uantity(Sets)

|

1 - 1

|

>1

|

|

Est. Time(days)

|

60

|

To be negotiated

|

Certifications

Our factory and facility

Recommend Products

Hot Searches