- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.2%

-

Voltage:

-

220V/380V/50HZ/60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PLANET MACHINE

-

Dimension(L*W*H):

-

2800*1500*2300(mm)

-

Weight:

-

1500 KG

-

Filling Material::

-

liquid detergents

-

Function:

-

filling and capping

-

Bottle type:

-

PET/HDPE bottle

-

Control:

-

PLC+ Touch Screen

-

Processing Types:

-

Piston Filling,weight filling

-

Product name:

-

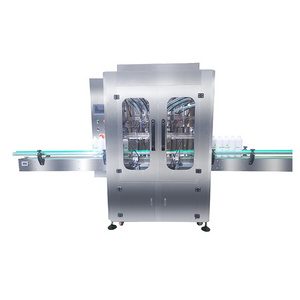

liquid detergents filling machine

-

Keywords:

-

Filling Machine

-

Capacity:

-

400-10000bph

-

Material:

-

Stainless Steel 304/316

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±0.2%

-

Voltage:

-

220V/380V/50HZ/60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PLANET MACHINE

-

Dimension(L*W*H):

-

2800*1500*2300(mm)

-

Weight:

-

1500 KG

-

Filling Material::

-

liquid detergents

-

Function:

-

filling and capping

-

Bottle type:

-

PET/HDPE bottle

-

Control:

-

PLC+ Touch Screen

-

Processing Types:

-

Piston Filling,weight filling

-

Product name:

-

liquid detergents filling machine

-

Keywords:

-

Filling Machine

-

Capacity:

-

400-10000bph

-

Material:

-

Stainless Steel 304/316

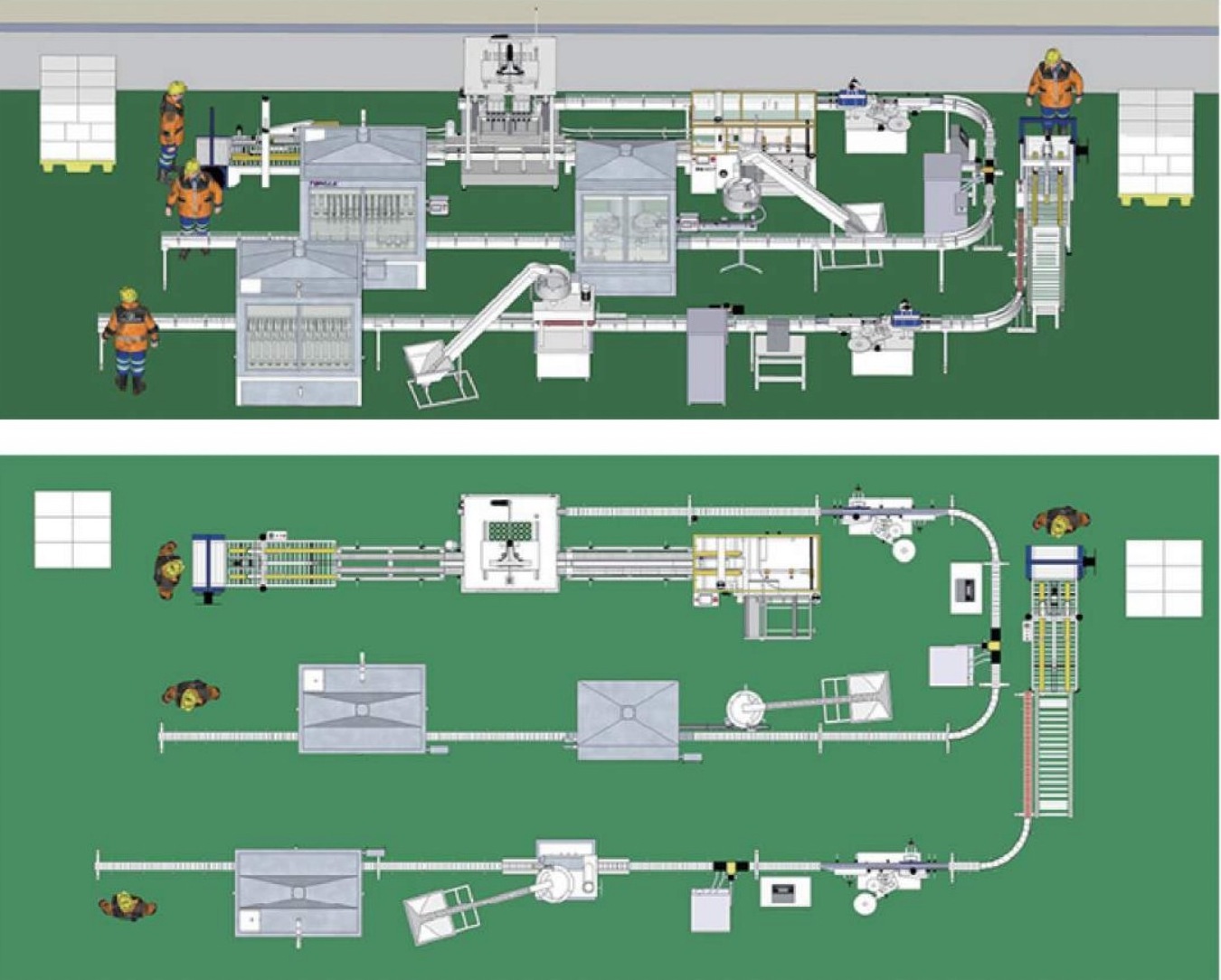

"Liquid Daily Chemicals filling production line From A-Z"

Products Description

liquid detergents filling machine

The daily chemical filling production line produced by Planet Machinery is suitable for various viscous and non viscous and corrosive liquid. Daily chemical filling machine series include: laundry detergent filling machine, hand sanitizer filling machine, shampoo filling machine, disinfectant filling machine, alcohol filling machine, etc.

The daily chemical filling equipment adopts linear filling, anti-corrosion materials, independent control of electrical cabinets, unique design, superior performance, other in conformity with the concept of international filling machinery and equipment.

The daily chemical filling equipment adopts linear filling, anti-corrosion materials, independent control of electrical cabinets, unique design, superior performance, other in conformity with the concept of international filling machinery and equipment.

Product Paramenters

|

Containers and Specifications

|

|

|

|

|

||||

|

Project Name:

Full Automatic Complete liquid detergents 500-5000bph Production Line |

|

|

|

Shampoo, laundry detergents, handwash fluid, dish sopa, sanitier, cream etc

|

||||

|

Material

|

Shape

|

Filling volume

|

Filling level(mm)

|

Neck type

|

||||

|

PET or HDPE bottle

|

round bottle or square bottle

|

200ml-25L

|

Distance from bottle neck

According request

|

As request

|

||||

|

Adjustable specifications

of the can type |

【Middle Mould Based on bottle diameter ≤350mm can Height≤ 550mm

|

|

|

|

||||

|

|

Customers need to buy additional change-over parts for the different cans.

If using square bottles, then bottle separating system will be added. |

|

|

|

||||

|

Container Label & Control Mode

|

|

Packaging system

|

|

Palletizing system

|

||||

|

Adhesive Label/shrink sleeve label Manual / Automaticc |

|

Packing system

|

Min, Spec.

|

Manual

Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer |

||||

|

|

|

Manual

shrink wrapper

carton packer Robert Packing Machine |

1*2

2*2

2*3

3*4

4*6

|

|

||||

|

User Ambient Conditions

|

|

Temperature:0~40℃; Humidity:No dew

|

|

|

||||

|

User Electrical Supply Specification

|

|

Voltage:380V±5%, 3phase; Frequency:50HZ±1%

|

|

|

||||

suitable products

Machine layout

Product Details

Filling nozzle

The filling nozzle will be chosen by different bottles and liquids.The lifting of them is controlled by servo ,so they can diving

into the bottle bottom to up with the liquid.Equipped with a anti-dripping tray.

into the bottle bottom to up with the liquid.Equipped with a anti-dripping tray.

Piston Cylinder

1.Use 316 stainless steel piston cylinder. 2.It can fill a variety of liquids, viscous materials, and is widely applicable. 3.It

is driven by imported servo motor to ensure the accuracy of filling.

is driven by imported servo motor to ensure the accuracy of filling.

auxiliary equipment

single head capping machine

Capacity:Up to 2500BPH

Automatic twist capping machine

Capacity:Up to 4500BPH

Two side adhesive labeling machine

capacity 100-4000bph

Case pack machine

capacity: 10-25 box/min

Hot Searches