- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Tianjin, China

-

Special Pipe:

-

Galvanized Hollow Section

-

Thickness:

-

0.3-40mm

-

Grade:

-

SGCC, DX51D, Q195

-

Delivery Time:

-

in 7 days

-

MOQ:

-

1 Piece

-

Processing:

-

Bending, Cutting, Drilling, Welding

-

Surface:

-

zinc coated

-

Usage:

-

structure, construction,fluid

Quick Details

-

Section Shape:

-

Square

-

Surface Treatment:

-

galvanized

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Tianjin, China

-

Special Pipe:

-

Galvanized Hollow Section

-

Thickness:

-

0.3-40mm

-

Grade:

-

SGCC, DX51D, Q195

-

Delivery Time:

-

in 7 days

-

MOQ:

-

1 Piece

-

Processing:

-

Bending, Cutting, Drilling, Welding

-

Surface:

-

zinc coated

-

Usage:

-

structure, construction,fluid

Products Description

Description

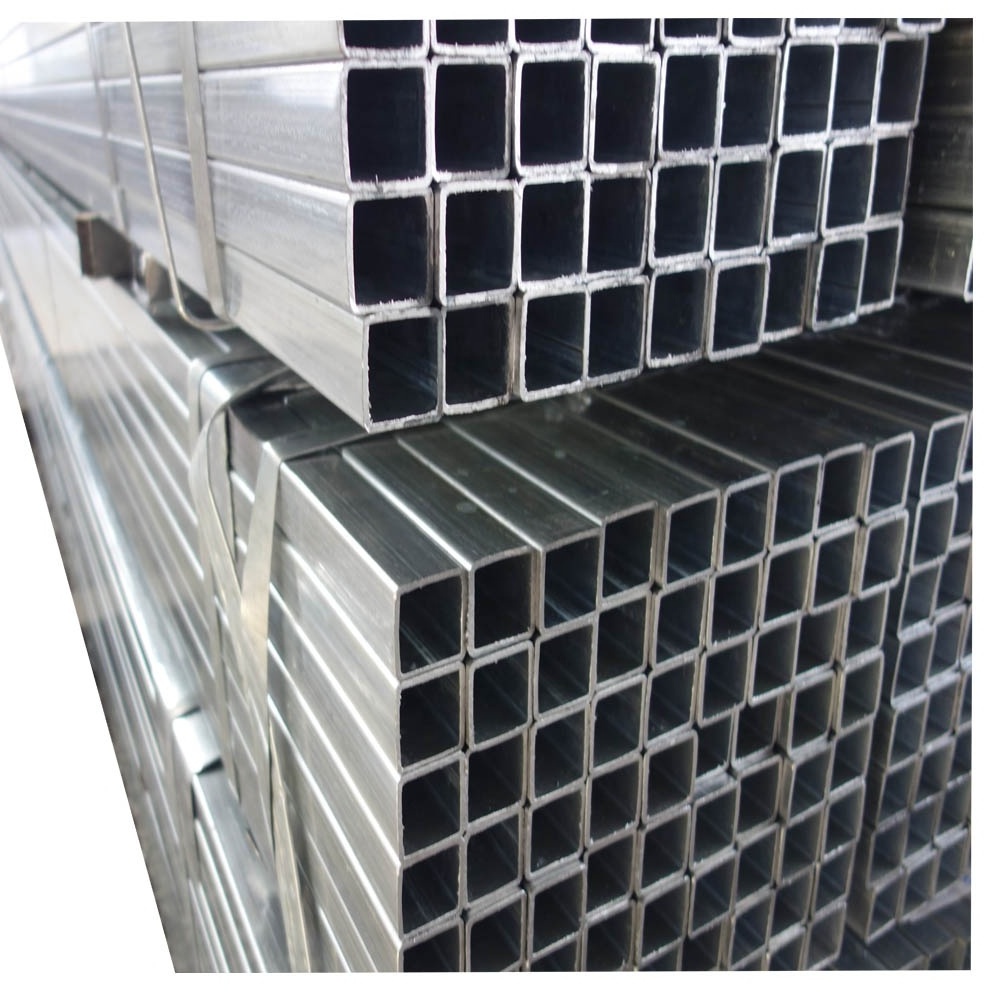

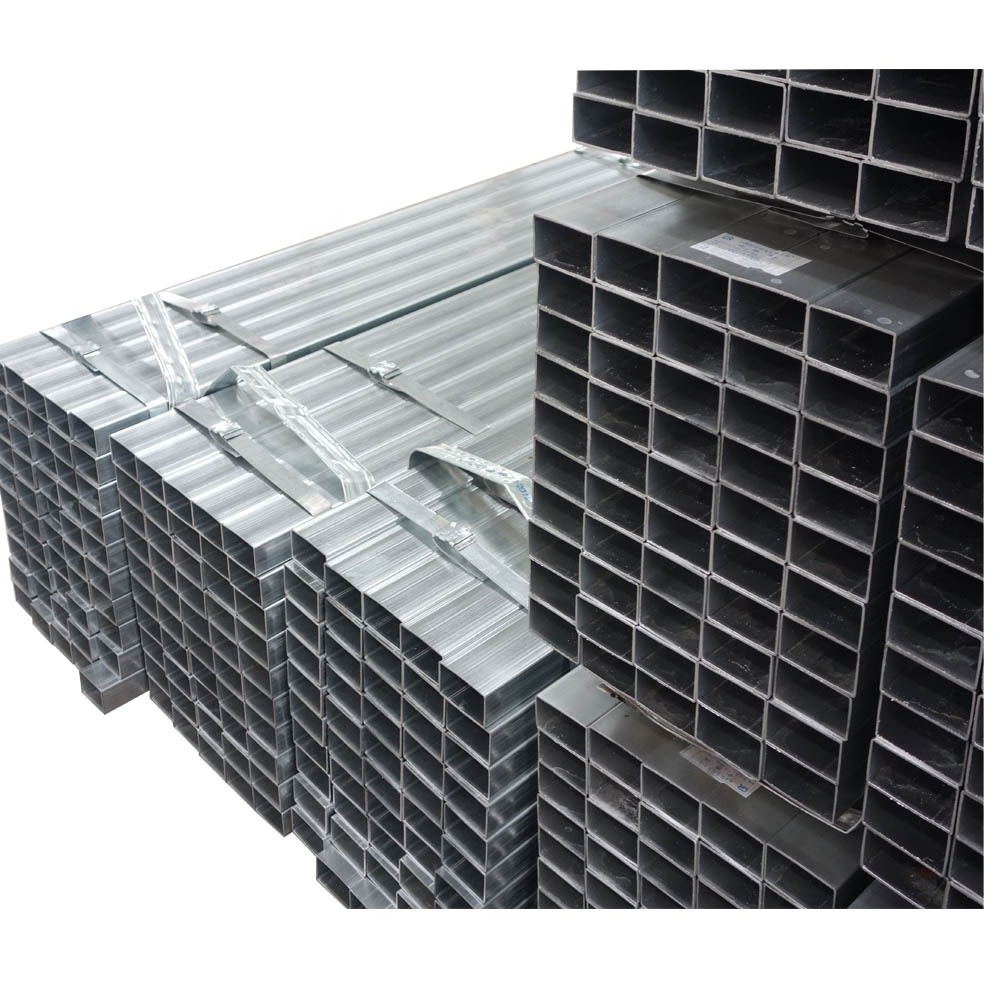

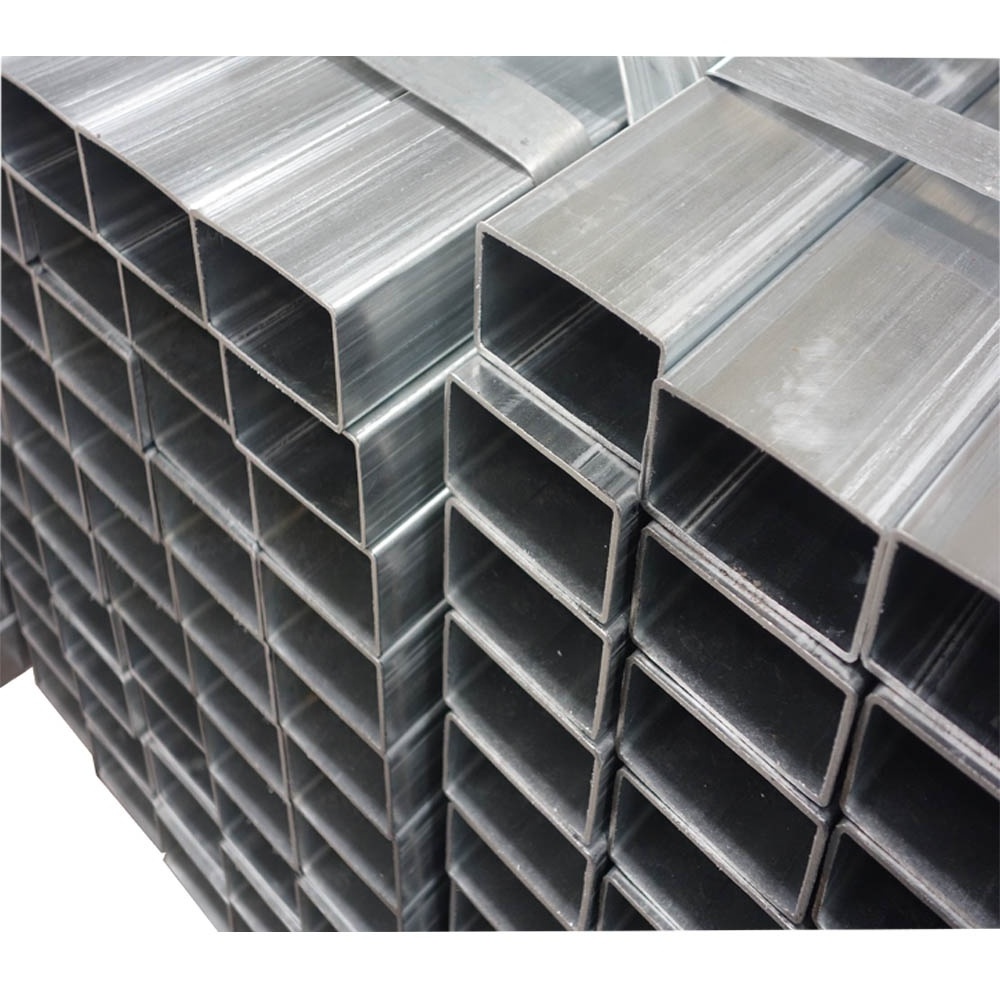

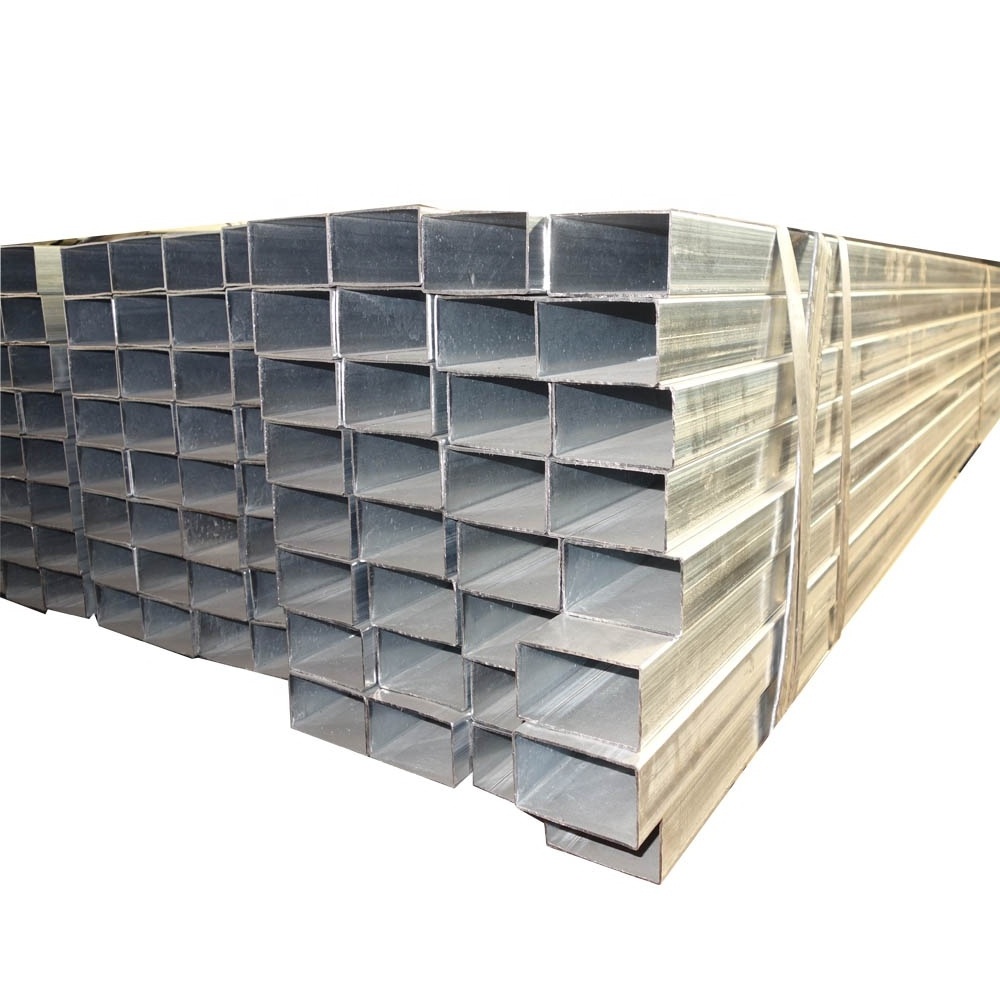

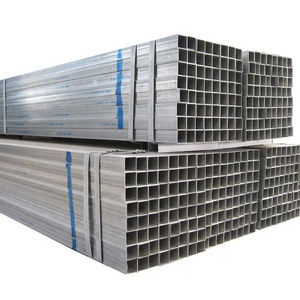

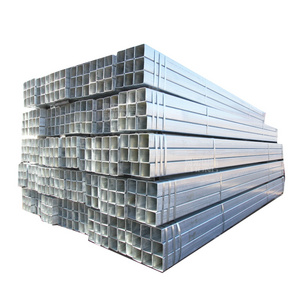

Zinc Steel Rectangular Metal Iron Square Pipe Tube

is in manufacturing process using steel pipes of removed rust dipped into zinc liquid of 500℃ temperatures, and making steel surface attached zinc layer so as to achieve the purpose of anti-corrosion.

Hot-dip galvanizing (HDG), as referenced is the process of dipping fabricated steel into a kettle or vat of molten zinc.

Hot-dip galvanizing (HDG) is the process of coating iron, steel or ferrous materials with a layer of zinc. This done by passing the metal through molten zinc at a temperature of 860°F (460°C) to form zinc carbonate (ZNC03). Zinc carbonate is a strong material that protects steel and can prevent corrosion in many circumstances. Hot-dip galvanizing can be carried out cheaply and in large batches. Because the square tube and rectangular tubes are galvanized, it is protected from rust and corrosion. Steel rusts after interacting with water or moisture in the air over time. By adding a coating of zinc to the tubing, galvanized steel round tubing corrodes much slower, extending the life of your tubing.

In addition to this, hot dipped galvanized square tube and rectangular tube also provides:

* Lower cost than stainless steel

* Lowest long-term cost

* Reliable performance

* Excellent resistance to mechanical damage

Hot-dip galvanizing (HDG), as referenced is the process of dipping fabricated steel into a kettle or vat of molten zinc.

Hot-dip galvanizing (HDG) is the process of coating iron, steel or ferrous materials with a layer of zinc. This done by passing the metal through molten zinc at a temperature of 860°F (460°C) to form zinc carbonate (ZNC03). Zinc carbonate is a strong material that protects steel and can prevent corrosion in many circumstances. Hot-dip galvanizing can be carried out cheaply and in large batches. Because the square tube and rectangular tubes are galvanized, it is protected from rust and corrosion. Steel rusts after interacting with water or moisture in the air over time. By adding a coating of zinc to the tubing, galvanized steel round tubing corrodes much slower, extending the life of your tubing.

In addition to this, hot dipped galvanized square tube and rectangular tube also provides:

* Lower cost than stainless steel

* Lowest long-term cost

* Reliable performance

* Excellent resistance to mechanical damage

|

Name

|

Zinc Coated GI Square Tube Hot-Dipped Galvanized Square Tube GI Square Tube HDG Square Tube

|

|

|

Grade

|

A500 Gr.A , A500 Gr.B, Q195, DX51D, SGCC

|

|

|

Square GI Tube

|

10x10x0.3-600x600x40mm

|

|

|

Rectangular GI Tube

|

10x15x0.3-600x800x40mm

|

|

|

Length

|

5.8m 6m 12m or To meet customer's demand

|

|

|

Tolerance

|

+-1%

|

|

|

Used Area

|

structure, construction

|

|

|

Standards

|

ASTM A500, EN10210, EN10219

|

|

|

Surface Treatment

|

hot dipped galvanized zinc coated

|

|

|

Packaging

|

Standard exporting packing or as client's requirement

|

|

|

Certificate

|

BV,ISO9001:2008 and Mill test Certificate

|

|

|

The above are the general items, for the special types, we can also meet your needs.

|

|

|

Factory Facility

Customer Photos

Hot Searches