- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Jianlong

-

Model Number:

-

None

-

Product Name:

-

Polyurea Coating

-

Material:

-

Polyurea

-

Status:

-

Liquid Coating

-

Type:

-

Waterproof, Anti-corrosion, Wear-resistant Materials

-

Feature:

-

Brilliant Colors, Tight Coating, Good Anti-corrosion Performance

-

Usage 1:

-

Concrete Protection, Wear-resistant Lining For Trucks

-

Usage 2:

-

Steel Structure Anti-corrosion, Roof Waterproofing, Others

-

Packing:

-

25 KG/Barrel

-

MOQ:

-

500 KG

Quick Details

-

CAS No.:

-

136210-30-5

-

Other Names:

-

Polyurea Coatings

-

MF:

-

-NH-CO-NH-

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Jianlong

-

Model Number:

-

None

-

Product Name:

-

Polyurea Coating

-

Material:

-

Polyurea

-

Status:

-

Liquid Coating

-

Type:

-

Waterproof, Anti-corrosion, Wear-resistant Materials

-

Feature:

-

Brilliant Colors, Tight Coating, Good Anti-corrosion Performance

-

Usage 1:

-

Concrete Protection, Wear-resistant Lining For Trucks

-

Usage 2:

-

Steel Structure Anti-corrosion, Roof Waterproofing, Others

-

Packing:

-

25 KG/Barrel

-

MOQ:

-

500 KG

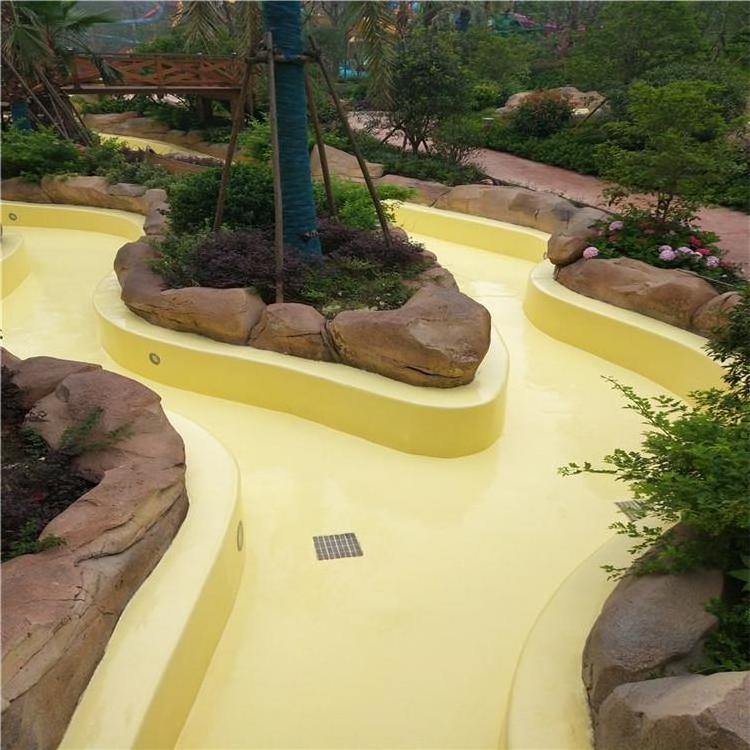

Spray Polyurea Coating Waterproofing Manufacturer Direct Sale Polyurea Waterproof Coating Components Polyurea

| Product Name | Polyurea Coating |

| Model | I |

| Solid Content | 99.2% |

| Gel Time | 11s |

| Dry Time | 23s |

| Tensile Strength | 13.6 MPa |

| Elongation At Break | 375% |

| Low Temperature Bending Resistance | -40 ℃ without cracks |

| Impermeability | 0.4MPa, 2 hour impermeability |

| Water Absorption Rate | 0.4% |

| Heat Treatment | |

| Tensile Strength Retention Rate | 114% |

| Elongation At Break | 310% |

| Low Temperature Bending Resistance | -35 ℃ without cracks |

| Alkaline Treatment | |

| Tensile Strength | 96% |

| Elongation At Break | 315% |

| Low Temperature Bending Resistance | -35 ℃ without cracks |

| Acid Treatment | |

| Tensile Strength Retention Rate | 91% |

| Elongation At Break | 301% |

| Low Temperature Bending Resistance | -35 ℃ without cracks |

| Salt Treatment | |

| Tensile Strength Retention Rate | 89% |

| Elongation At Break | 300% |

| Low Temperature Bending Resistance | -35 ℃ without cracks |

| Hardness | 82 (Shore A) |

| Impact Resistance | 1.0 kg · m |

How to do a good job in treating the polyurethane anti-corrosion base layer?

Polyurea, due to its unique weather resistance, UV resistance, anti yellowing, acid and alkali resistance, solvent resistance, instant curing, self-cleaning, and wear resistance, has been highly valued in the anti-corrosion industry and is widely used for surface corrosion protection of concrete and metal structures. In the process of polyurea construction, there are very high requirements for the treatment of the base layer surface. In addition to the rigid requirement of controlling the concrete moisture content below 6%, strict control must also be carried out on the concrete surface treatment to ensure the adhesion between polyurea and the base layer concrete. Of course, for the surface treatment of carbon steel and non-ferrous metals, in addition to meeting the requirements specified in GB8923, the influence of roughness on adhesion must also be considered.

Firstly, there are requirements for spraying polyurea on concrete foundations. Newly made concrete must ensure a moisture content of less than 6%, and must not sand. Try to maintain a certain level, that is, a 2MI straightedge should be laid flat, and the height of the surface gap of the concrete should not exceed 3 millimeters. If there are honeycombs or voids in the foundation, high-grade quick setting cement must be used for repair. If there are sand running defects, sand fixing agents must be used for sand fixation.

Old concrete layers must have surface attachments removed, such as paint, coatings, or other substances (waterproof rolls, etc.). If oil stains seep into the ground, a spray gun needs to be used for hot drying to remove oil, and attention should be paid to the baking temperature not to cause damage to the concrete structure.

After all surface cleaning work is completed, use a 300 concrete floor self suction grinder for dry grinding until the natural pores of the concrete are exposed. According to the needs, coarse grinding and fine grinding can be selected, and a vacuum cleaner can be used to thoroughly remove dust. A polyurethane specific primer can be applied to fully wet and penetrate. Apply a layer of polyurea specific putty on top of the dry primer, polish and vacuum it for later use, to create a clean, good, and flat concrete foundation surface for polyurea thermal spraying.

The second requirement is the surface treatment of carbon steel and non-ferrous metals by spraying polyurea. Carbon steel must undergo dry sandblasting treatment. As environmental protection requirements become increasingly stringent, wet sandblasting, water sandblasting, or water jet treatment may also occur. However, the author still does not recommend surface treatment with water, which is related to the characteristics of polyurea.

Dry sandblasting treatment should require Sa2.5 grade as much as possible, and non-metallic substances such as garnet and quartz sand should be used as much as possible to meet the requirements of GB8923 standard. If this condition cannot be met, manual mechanical polishing can be chosen. It is recommended to use sandpaper or louvers for polishing, and the grade must reach St3 or above. Cross cutting should be carried out to create a certain surface roughness as much as possible, avoiding pollution and lubrication layer surface caused by wire wheel polishing. Use dry and oil-free clean compressed air to blow away surface dust. For manually polished surfaces, if conditions permit, alcohol can be used for cleaning. During the cleaning process, pay attention to good ventilation and maintain safety.

The surface density of non-ferrous metals is much higher than that of carbon steel. The author does not recommend manual polishing, and must use dry sandblasting and light sweeping to increase the surface roughness. Based on experience, a roughness of about 40 microns is sufficient. Whether it is carbon steel surface treatment or non-ferrous metal surface treatment, the selection of primer is very important. The author suggests choosing a cathodic stripping resistant primer, which can fully meet the adhesion requirements of polyurea spraying. Among them, the pull-out test of a special polyurea primer has reached 11.2MPa.

In short, the use of polyurea, a corrosion-resistant and waterproof material, is a high-quality product. Otherwise, it will become garbage. The key to determining the success or failure of this quality lies in the treatment quality of the base layer and the selection of the primer. The author has seen from a large number of cases that 70% of the quality of polyurea lies in grassroots treatment, and 30% lies in materials and processes.

If you master these two points, you will be like a fish in water using this high-end anti-corrosion and waterproof material. In today's environmentally friendly world, it is believed that the VOC content is required to be less than 10% lower than the quality of your own coating, or high solid content materials without VOC are increasingly favored by the anti-corrosion industry. Among them, solvent-free coatings, thermal spray polyurea, electrophoretic coatings, and powder coatings water-based coatings have the highest heat.

Q1: Are you a manufacturer?

Answer: Yes, we are a manufacturer founded on 2014.

Q2: Which kind of payment terms do you accept?

Answer: For small order, you can pay by T/T, Western Union or Paypal. For nomal order by T/T or LC to our company account.

Q3: Can you give me a discount price?

Answer:Surely, It depends on your quantity.

Q4: How can I get a sample?

Answer: The samples are free, but freight charges will be at your account and the charges will be returned to you or deduct from

your bulk order in the future.

Q5: How to confirm the Product Quality before placing orders?

Answer: You can get free samples for some products, you only need to pay the shipping cost or arrange a courier to us and take the

samples. You can send us your product specifications and requests, we will manufacture the products according to your requests.

Q6: How do you treat quality complaint?

Answer: First of all, our quality control will reduce the quality problem to near zero. In case there is a real quality problem caused by us, we will send you free goods for replacement or refund your loss.