- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Famous Shandong Brand

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1200*1300*1200mm

-

Weight:

-

14000 kg

-

Product name:

-

Automatic Paper Folding Machine

-

Application:

-

Corrugated Board

-

Name:

-

Filter Paper Pleating Machine

-

Keyword:

-

Tissue Paper Cutting Machine

-

Machine type:

-

Multifunction

-

Usage:

-

Carbon Fliter

-

Model:

-

Ml-1300

-

Local Service Location:

-

Oversea Warehouses

-

Material:

-

304 Stainless Steel

-

Output paper:

-

Liner Paper

Quick Details

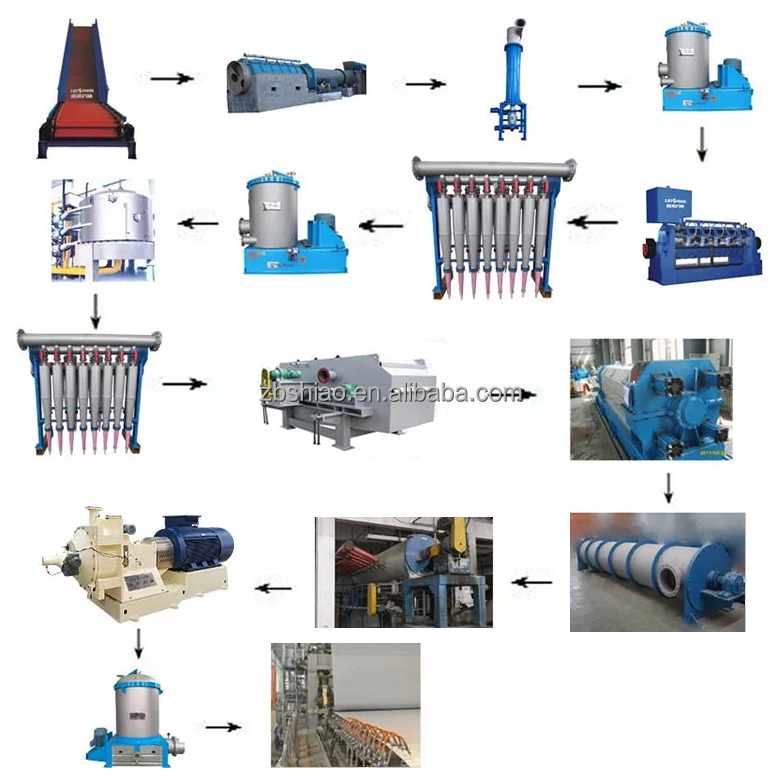

-

Type:

-

Pulping Equipment

-

Production Capacity:

-

350 m/min

-

Max. workable width:

-

350mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Famous Shandong Brand

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1200*1300*1200mm

-

Weight:

-

14000 kg

-

Product name:

-

Automatic Paper Folding Machine

-

Application:

-

Corrugated Board

-

Name:

-

Filter Paper Pleating Machine

-

Keyword:

-

Tissue Paper Cutting Machine

-

Machine type:

-

Multifunction

-

Usage:

-

Carbon Fliter

-

Model:

-

Ml-1300

-

Local Service Location:

-

Oversea Warehouses

-

Material:

-

304 Stainless Steel

-

Output paper:

-

Liner Paper

Product Description

Specification

|

Core Components

|

Bearing, Gear, Gearbox, PLC, pulping zone, screening zone

|

|

PLC Brand

|

Siemens, ABB, other

|

|

Condition

|

New

|

|

Computerized

|

Yes

|

Packing & Delivery

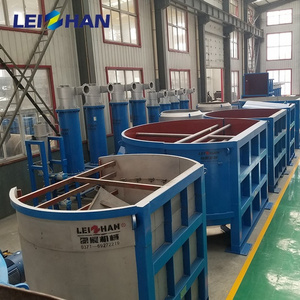

Hydrapulper Paper Pulp Drum Pulper feature

1.This single machine is able to continuous pulp and primarily coarse screen, simplifying the following purge and separation.

2.Deflaking force on fibers is not severe so that the physical characteristic of fiber can be kept to the largest extent.

3. the largest extent.Longer pulping time brings sufficient deflaking. Loss rate of good fiber is no more than 0.8%.4.Lower specific energy consumption and less operation cost, almost no quick-wear part, 7*24h continuous work is permissible,

lower maintenance cost.

5.Less size reduction of contaminants and higher reject discharging efficiency, reduce burdens of downstream processes.

1.This single machine is able to continuous pulp and primarily coarse screen, simplifying the following purge and separation.

2.Deflaking force on fibers is not severe so that the physical characteristic of fiber can be kept to the largest extent.

3. the largest extent.Longer pulping time brings sufficient deflaking. Loss rate of good fiber is no more than 0.8%.4.Lower specific energy consumption and less operation cost, almost no quick-wear part, 7*24h continuous work is permissible,

lower maintenance cost.

5.Less size reduction of contaminants and higher reject discharging efficiency, reduce burdens of downstream processes.

Hot Searches