- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2001

-

Brand Name:

-

Faygo Union

-

Dimension(L*W*H):

-

2.0m*1.8m*2.0m

-

Weight (KG):

-

5000

-

Product name:

-

20 ltr 5 gallon mineral water filling bottling machine production lin

-

Filling heads:

-

12 for 3-in-1 bottle washing filling capping machine

-

Suitable for:

-

PET bottle, Plastic bottle

-

Capacity:

-

5000-30000BPH

-

Height:

-

150-310mm

-

Main motor power:

-

1.5kw

-

Suitable cup:

-

Plastic screw cap

-

Diameter of bottle:

-

55-100mm for 3-in-1 bottle washing filling capping machine

Quick Details

-

Production Capacity:

-

5000kgh

-

Voltage:

-

220v/380v for 3-in-1 filling machine

-

Place of Origin:

-

Jiangsu, China

-

Year:

-

2001

-

Brand Name:

-

Faygo Union

-

Dimension(L*W*H):

-

2.0m*1.8m*2.0m

-

Weight (KG):

-

5000

-

Product name:

-

20 ltr 5 gallon mineral water filling bottling machine production lin

-

Filling heads:

-

12 for 3-in-1 bottle washing filling capping machine

-

Suitable for:

-

PET bottle, Plastic bottle

-

Capacity:

-

5000-30000BPH

-

Height:

-

150-310mm

-

Main motor power:

-

1.5kw

-

Suitable cup:

-

Plastic screw cap

-

Diameter of bottle:

-

55-100mm for 3-in-1 bottle washing filling capping machine

Product introduction

1.Our mahine can be used to produce bottled mineral water, purified water, alcoholic beverage and other non-gas Liquid. This Machine can be applied to all kinds of plastic machine such as PET, PE.

2.Bottles size can vary from 200ml-2000ml meanwhile few changeover is needed.

3.This model of filling machine is designed for the low/middle capacity and small factory. It takes low buying cost, low water and electricity consumption and few space occupation into consideration at the beginning.

4.At the same time it can perfectly complete the function of washing, filling and capping.

5. It improves the sanitary conditions and simplifies the maintenance compared with the last generation water filling machine.

Product Details

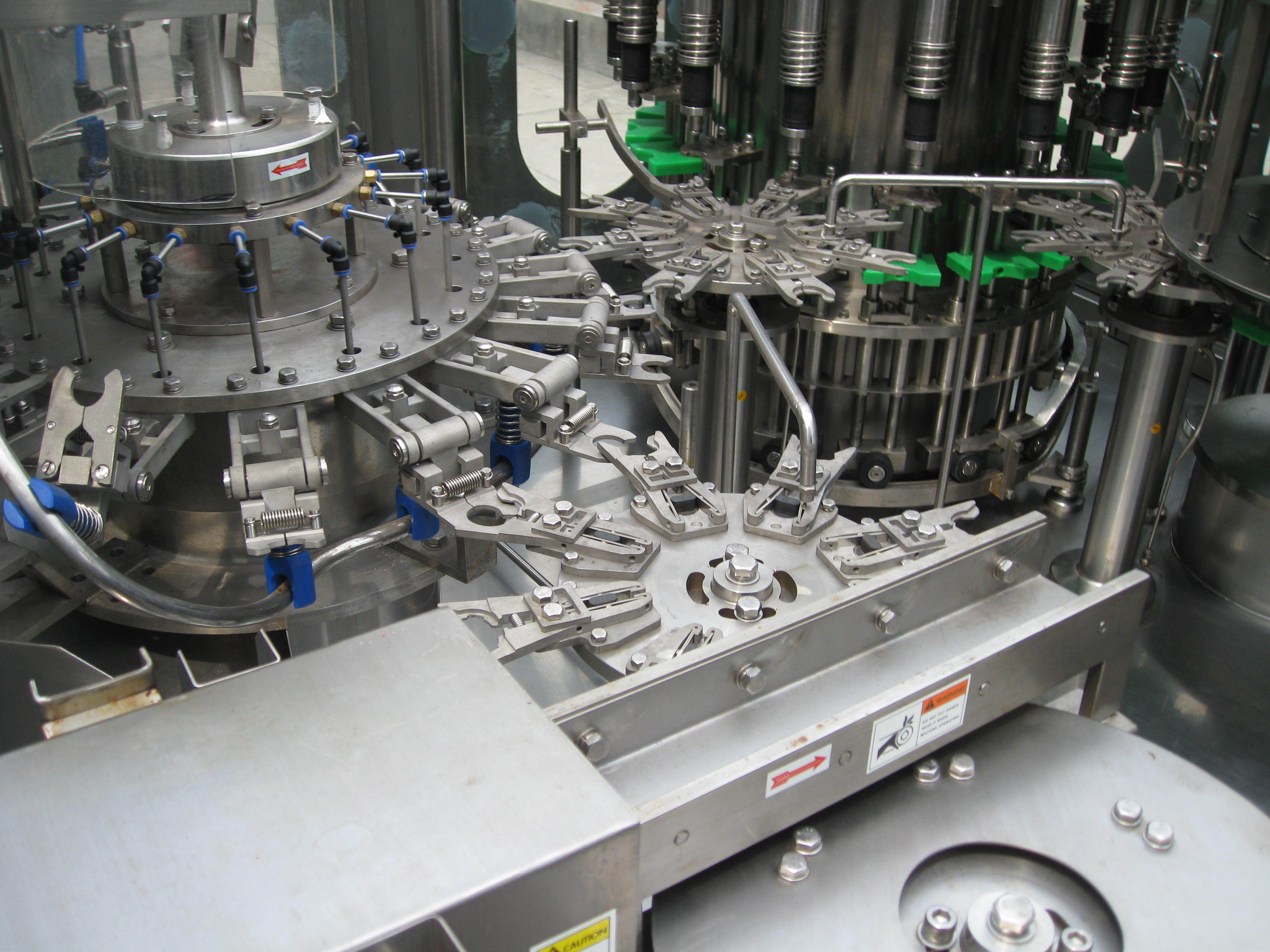

Washing part

Rotary type bottle washing machine, mainly used to wash bottles for drinking water and other beverage. New bottles go into the machine through air conveyor. Bottles are held by grips and turned over onto washing heads. After washing and drain water, bottlesgo into filling parts by star wheel. Main structure, protect shell and contact water part of washing part are all stainless steel.

Filling part

Filling machine adopt German technology, produce by gravity filling and obey to normal pressure filling principle.Main drives adopt mechanical freestanding gear, high efficiency, low noise, long service life, easy to maintain, lubricate well. Frequency converter controls the main motor and makes the machine speed changeable.

Capping part

Capping machine drives revolved plate by gear. Cap goes out of cap storage by centrifugal effect. At the cap output, there is cap divider. Reverse cap drops into pipes then return to cap storage by air conveyor. Right cap goes into conveyor. The quantity inspected by sensor, capping machine control the cap conveyor. The machine will stop when no caps.

productions

This Automatic Wash-filling-capping Water Filling Machine is used to produce bottled mineral water, purified water, flavored water, alcoholic beverage and other non-gas Liquid. This Machine can be applied to all kinds of plastic products such as PET, PE.Bottles size varies from 250ml-2500ml meanwhile few changeover is needed. This series of filling machine capacity varies from3000BPH to 32000BPH.

Product parameter

|

Model

|

Unit

|

FG12-1

|

FG18-4

|

FG24-6

|

FG32-8

|

|

Can Volume

|

ML

|

200-2000

|

200-2000

|

200-2000

|

200-2000

|

|

Can diameater

|

MM

|

50-70

|

50-70

|

50-70

|

50-70

|

|

Bottle high

|

MM

|

120-180

|

120-180

|

120-180

|

120-180

|

|

Machine power

|

KW

|

1.5

|

2.2

|

3.7

|

5.5

|

|

Machine size

|

CM

|

175*120*195

|

305*175*220

|

340*195*220

|

350*235*225

|

|

Weight

|

KG

|

1200

|

2000

|

2500

|

2900

|

|

Capacity

|

BPH

|

1500

|

6000

|

9000

|

120000

|

Advantages

1. intelligent contact screen, human design, easy operation.

2. Imported filling valve, avoiding drop leaking, accurate fillingquantity.

3. Program logic controller(PLC), easy for changing size or modifying parameters.

4. Pneumatic elements are all imported, stability and reliability.

5. Accurate liquid sensing, automatically adding liquid, ordinary pressure flow passage parameters

6. Solely and specially-designed whole lifting device, easy governing to meet the needs of all kinds of container packing.

7. Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle.

8. Pneumatic executive control valve, high efficiency and safety. Each flow passage can be separately cleaned.

9. Close positioning design, easy governing, suitable for packing of all sizes of bottles.

10. The whole machine is designed according to requirements of buyer's.

3. Program logic controller(PLC), easy for changing size or modifying parameters.

4. Pneumatic elements are all imported, stability and reliability.

5. Accurate liquid sensing, automatically adding liquid, ordinary pressure flow passage parameters

6. Solely and specially-designed whole lifting device, easy governing to meet the needs of all kinds of container packing.

7. Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle.

8. Pneumatic executive control valve, high efficiency and safety. Each flow passage can be separately cleaned.

9. Close positioning design, easy governing, suitable for packing of all sizes of bottles.

10. The whole machine is designed according to requirements of buyer's.

Application

FG series bottled water filling machine line is used to filling mineral water or purified water into PET bottle from

200ml-2000ml.Different models can satisfy various requirement of output from 2000BPH to 36000BPH.The machine combines washing,filling and capping three function in a body, the whole process is automatic, suitable for PET bottle, plastic bottle filling mineral water and pure water.

200ml-2000ml.Different models can satisfy various requirement of output from 2000BPH to 36000BPH.The machine combines washing,filling and capping three function in a body, the whole process is automatic, suitable for PET bottle, plastic bottle filling mineral water and pure water.

Filling way using the gravity or micro pressure filling, make the speed is faster and more stable, so with the same model our machine output is higher and more efficient.The machine adopts advanced Mitsubishi programmable controller (PLC) to control the machine to run automatically, interworking with inverter running more stable and reliable.The photoelectric sensor detect all part running state, with high degree of automation, easy operation.

Related products & questions

F4 auto bottle blowing machines

Cavity number:4

Operation speed: 4000-4500BPH

Operation power:28kw

Operation speed: 4000-4500BPH

Operation power:28kw

F8 auto bottle blowing machines

Cavity number:8

Operation speed: 12000-13000BPH

Operation power:45kw

Operation speed: 12000-13000BPH

Operation power:45kw

Semi-auto bottle blowing machines

Cavity number:4

Operation speed: 300-600BPH

Operation power:17.5kw

Operation speed: 300-600BPH

Operation power:17.5kw

Packaging & shipping

Packing: Film covered or wooden box package(According to customer needs )

Delivery: 30-45 working days

Port: Shanghai port

Delivery: 30-45 working days

Port: Shanghai port

Certifications and Factory Show

Jiangsu Faygo Union Machinery Co., Ltd. adheres to the business philosophy of "integrity and win-win", adheres to the customer first and quality, serves customers with science and technology, adheres to technological progress, continuous innovation and continuous surpassing, and has become an enterprise with strength and scale in the rubber and plastic industry. We work closely with you to ensure your emoloyees have the skills needed to ensure the safety and efficiency of line. We can serve you with the most sincere attitude and the best technology. Your satisfaction is our pursuit.

Professional Extrusion and Recycling Technology

1.FAYGO UNION

Faygo is a new high-tech entreprise covering 20000㎡, which specializes in reserching and manufacturing blowing

blowing machines.

2.PRODUCTS

PVC/HDPE/PP-R pipe extrusion line, plastic sheet production line and relative auxiliary machines,PE film/PETbottles recycling line

and pelletizing line.

3.MARKETING

Our products have been exported to Middle East, Southeast Asia, South America and Europe etc. We've received universal

confirmation and trust from our customers.

4.IDEA

Making good machine, Bing good person.

Our costumers

Our services

1.High-quality equipment and highly competitive market prices can bring you more profits.

2.We have a one-year warranty and can provide long-term technical support.

3.Years of experience in the reserch of plastic extruders enable us to solve most of the

problems and improve efficiency.

problems and improve efficiency.

4.Send Your Inquire Details In The Below Click "Send" Now!

Hot Searches