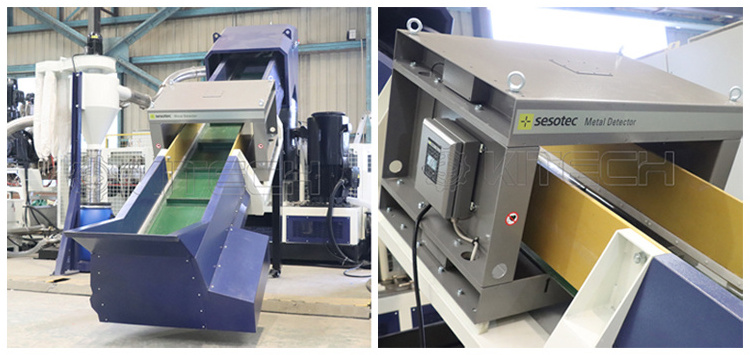

>>Metal detector can be installed on conveyor as optional item, Detecting and separating the metal to protect the compactor and extruder effectively.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380/440/480v

-

Dimension(L*W*H):

-

15000*6000*3800mm

-

Power (kW):

-

132-650

-

Weight:

-

7000

-

Screw Speed (rpm):

-

90 - 150 rpm

-

Raw material:

-

Waste PE PP film / Woven bag

-

Automatic:

-

full automatic

-

Process:

-

Feeding Compacting Pelletizing

-

Final product:

-

Recycled PP PE PS Plastic Granules

-

Capacity:

-

200-1000 KG/H

-

Motor brand:

-

WEG / SIEMENS

-

Usage:

-

Waste Plastic Recycling

-

Certification:

-

CE ISO

-

Keywords:

-

plastic granules making machine

Quick Details

-

Output (kg/h):

-

150 - 1200 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KITECH

-

Voltage:

-

220/380/440/480v

-

Dimension(L*W*H):

-

15000*6000*3800mm

-

Power (kW):

-

132-650

-

Weight:

-

7000

-

Screw Speed (rpm):

-

90 - 150 rpm

-

Raw material:

-

Waste PE PP film / Woven bag

-

Automatic:

-

full automatic

-

Process:

-

Feeding Compacting Pelletizing

-

Final product:

-

Recycled PP PE PS Plastic Granules

-

Capacity:

-

200-1000 KG/H

-

Motor brand:

-

WEG / SIEMENS

-

Usage:

-

Waste Plastic Recycling

-

Certification:

-

CE ISO

-

Keywords:

-

plastic granules making machine

PRODUCT OVERVIEW

KCP Series Compacting Water Ring Plastic Pelleting Machine

KCP series compacting pelletizing system, it is a three in one recycling machine designed for low density plastic articles. It

could provide the excellent re-pelletizing and recycling solution for film,raffia, filament, woven bag and nonwoven fabric and other consumed / post soft or rigid plastic.Our pellet making machine has a wide application in PE, PP, CPP, BOPP, PS, PPS, EPS, ABS, PA,PLA, PET waste plastic materials recycling field.

|

Technology Parameters

|

|

|

|

|

|

|

|

|||||||

|

Type

|

|

KCP80

|

KCP100

|

KCP120

|

KCP140

|

KCP160

|

KCP180

|

|||||||

|

Capacity(kg/h)

|

|

150-250

|

300-420

|

400-600

|

600-750

|

800-950

|

1000-1200

|

|||||||

|

Energy consumption(kWh/kg)

|

|

0.2-0.33

|

0.2-0.33

|

0.2-0.33

|

0.2-0.33

|

0.2-0.33

|

0.2-0.33

|

|||||||

|

Length(mm)

|

|

10,300

|

10,300

|

11,400

|

11,400

|

14,800

|

14,800

|

|||||||

|

Width(mm)

|

|

6,200

|

6,200

|

6,450

|

6,450

|

6,850

|

6,850

|

|||||||

|

Height(mm)

|

|

3,500

|

3,750

|

3,980

|

4,250

|

4,460

|

4,850

|

|||||||

|

Compactor

|

Volume(L)

|

300

|

500

|

800

|

1000

|

1200

|

1400

|

|||||||

|

|

Motor Power(kw)

|

37-45

|

55-75

|

75-90

|

90-132

|

132-160

|

160-185

|

|||||||

|

Extruder

|

Screw Diameter(mm)

|

φ80

|

φ100

|

φ120

|

φ140

|

φ160

|

φ180

|

|||||||

|

|

L/D

|

30-40

|

30-40

|

30-40

|

30-40

|

30-40

|

30-40

|

|||||||

|

|

Motor power(kw)

|

55-75

|

90-110

|

132-160

|

160-200

|

250-315

|

315-355

|

|||||||

|

Filter

(options)

|

Two position plate type

|

●

|

●

|

●

|

●

|

●

|

●

|

|||||||

|

|

Two position piston type

|

○

|

○

|

○

|

○

|

○

|

○

|

|||||||

|

|

Back flush piston type

|

○

|

○

|

○

|

○

|

○

|

○

|

|||||||

|

|

Automatic selfcleaning type

|

○

|

○

|

○

|

○

|

○

|

○

|

|||||||

|

2nd Extruder

(optional)

|

Screw Diameter(mm)

|

φ100

|

φ120

|

φ150

|

φ150

|

φ180

|

φ200

|

|||||||

|

|

L/D

|

10-18

|

10-18

|

10-18

|

10-18

|

10-18

|

10-18

|

|||||||

|

|

Motor power(kw)

|

37-45

|

45-55

|

55-75

|

75-90

|

90-110

|

110-160

|

|||||||

|

Downstream(options)

|

Water ring pelletizer

|

●

|

●

|

●

|

●

|

●

|

●

|

|||||||

|

|

Strand pelletizer

|

○

|

○

|

○

|

○

|

○

|

○

|

|||||||

|

|

Automatic strand pelletizer

|

○

|

○

|

○

|

○

|

○

|

○

|

|||||||

|

|

Underwater pelletizer

|

○

|

○

|

○

|

○

|

○

|

○

|

|||||||

●standard

○alternative

GOOD QUALITY FROM DETAILS

We are confident about our product quality because of the Quality Assurance System backed by technical capabilities and production capacity.

We believe “all steps in production are quality control processes”.

Belt conveyor

>>Belt conveyor as standard feeding device for plastic film, raffia, filament, woven bag, nonwoven fabric, etc.

Compactor and Drying & Dedust unit

>>With optimal design of rotary blades and stationary blades.

>>The material got cutting, mixing and compacting in the compactor uniformly, to ensure the material heated and dried effectively which guarantee a fast and stable feeding from the compactor into the extruder.

>> Drying & Dedust unit can be fixed at top of the compactor as optional item. To remove the dust and moisture from compactor while compactor running.

>> Drying & Dedust unit can be fixed at top of the compactor as optional item. To remove the dust and moisture from compactor while compactor running.

Nip roller

>>Nip roller can be install at the top of compactor for film rolls feeding.

Sliding gate

>>Sliding gate can be designed on compactor as optional item for rigid flakes processing.

>>With serve motor to control the feeding amount into extruder automatically, make sure the extruder run steady.

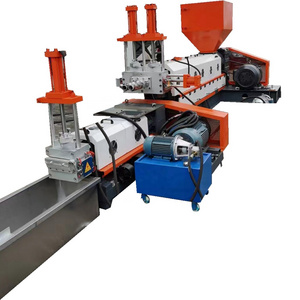

Single screw extruder

>>Referring to the Germany design concept and method, designed for single screw extrusion machine, with the structure of involute gear teeth.

>>High efficiency and low noise, Long use life and low maintenance cost.

Degassing unit

>>Force vacuum degassing system with two vents to get rid of the low molecular, moisture and printing ink effectively, make sure high quality output products.

Filter

>>Plate type, pistion type and automatic self-cleaning type filter, Different choice according to impurity contents in material and client’s habit.

>>Plate type filter is cost-effective and easy to operate which mainly used for regular thermoplastic as usual

filtration solution.

filtration solution.

Water ring pelletizer

>>Cutting speed of pelletizer controlled automatically by PLC according to the pressure of die head, which could achieve the uniform size for output pellets.

>>Blades of pelletizer touch to die plate automatically by pneumatic system, make sure blades contact with die plate properly, easy to operate and abrasion avoided.

Vibration dryer

>>With heater exchanger at water tank for cooling. Make the water recycling.

>> All accessories and pipe system have soundproof

enclosure with low noise.

>>Two-part filter design, the right side of the water will filter out most of the unqualified particles, the left side will filter

out excessive spilled water impurities, play an auxiliary role.

enclosure with low noise.

>>Two-part filter design, the right side of the water will filter out most of the unqualified particles, the left side will filter

out excessive spilled water impurities, play an auxiliary role.

Centrifugal dryer

>>Centrifugal drying system can get final pellet humudity less than 1%.

>>The brand of the motor is Siemens original motor and the

bearings are SK from Japan,Speed up to 1440 rpm per min.

bearings are SK from Japan,Speed up to 1440 rpm per min.

>>Horizontal design of dewaterer with small floor area.

Silo

>>The function of the blower is to transport particles to the silo through stainless steel pipes.

>>Pipes and silos are wrapped with black sound insulation cotton, which reduces the volume from 82dB to 68dB. >>New design makes it easier to operate.

PLC

>>PLC & Touch screen controller to control the whole system automaticlly .

>>One button " start" to start whole system as per processing technic.

>>One button " stop" to stop machine with proper sequence >>Brand:Siemens brand.

>>One button " stop" to stop machine with proper sequence >>Brand:Siemens brand.

Electrical control cabinet

>>All electrical units mounted in a strong safe electrical cabinet;

>>Safety interlock principle applied in the system;

>>Inverter:ABB/FUJI/DELTA;

>>Inverter:ABB/FUJI/DELTA;

>>Contactor: Schneider;

>>Adopt CE safety electrical components;

>>Solid state relay is optional for heating control.

RAW MATERIAL&FINAL PRODUCT

We are confident about our product quality because of the Quality Assurance System backed by technical capabilities and production capacity.

We believe “all steps in production are quality control processes”.

MORE PRODUCTS

We are confident about our product quality because of the Quality Assurance System backed by technical capabilities and production capacity.

We believe “all steps in production are quality control processes”.

KITECH MACHINE SERVICE

KITECH Machine Service gives you fast and easy online access to your Installed Base to order your original spare parts and explore the Options & Upgrades relevant for your line. Designed to make your life easier in your day to day business,it will help you to improve your line and maintain its performance.

7/24 Online Service

1 - Machine running video

2 - Watch our factory online

3 - More service contact us

Successful Plastic Recycling Plant

1 - Supply a running plastic recycling line in your country , you can see machine running directly.

Installation / Debug / Training

1 - We will arrange seasoned technician for equipment installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

After-sales Service

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems。

3 - After quality guarantee, we offer technical support and after-sales service.

CUSTOMER FEEDBACK

KITECH Machine is a professional manufacturer of plastic recycling machinery in China.With the scientific progressive conception of rapid introduction, we make our machinery cover all over the overseas market. We have been producing our goods with mature techniques and first-class quality.

We warmly welcome customers all over the world to visit our manufacture.

ABOUT KITECH MACHINE

We are confident about our product quality because of the Quality Assurance System backed by technical capabilities and production capacity.

We believe “all steps in production are quality control processes”.

JIangsu KITECH Machinery Co.,Ltd

1 / Kitech is a global machinery corporation,specialized in plastic extrusion and recycling system over 25 years,devote to create equipment with high level of innovation.

2 / We are located in Zhangjiagang,Jiangsu Province,China,with convenient transportation access,and have over 120 employees,the plant area is nearly 5000㎡,our well equipped facilities and excellent quality control throughout all the stages of production, enable us to guarantee total customer satisfaction.

3 / As a result of our high quality products and outstanding customer service,we have provide many turnkey project to clients and are greatly appreciated in a variety of different markets all over the world.

4 / Kitech is committed to become a world-renowned equipment manufacturer,create a healthy and fresh living environment for mankind.

KITECH Machine Sales Manager Team and Engineer Team

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

KITECH Machine Certificate and Patents

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in KITECH machine .

Verification Certificates of equipments: CE Certificate , SGS , TUV

National Certificate of equipment verification:Logo trademark registration.

FAQ

HOW TO FIND KITECH MACHINE?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactruer and not traders

● Visit exhibition in different countries

● Send Kitech Machine an request and tell your basic inquiry

● Kitech Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can full fill your request and you interested in our products, you may pay a visit to Kitech Machine site

● The meaning of visiting supplier, because seeing is believing, Kitech Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE KITECH MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KITECH MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Enginee

, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Hot Searches