- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HENGYU

-

Year:

-

2021

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5.5mx1.8mx1.9m

-

Hollow part volume:

-

200-2000ml

-

Clamping Force (kN):

-

1000

-

Power (kW):

-

49

-

Weight (KG):

-

3900 KG

-

Suitable bottle:

-

Drink Bottle

-

Machine type:

-

Stretch Bottle Blowing

-

Bottle material:

-

Pet Plastic

-

Capacity:

-

9000BPH

-

Advantages:

-

Saving Energy

-

Cavity:

-

6-cavity

-

Fully Auto:

-

Servo motor

-

Processing Type:

-

Stretch Blowing

-

Raw material:

-

PET Tube

-

Machine Weight:

-

5.0 Ton

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

105 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HENGYU

-

Year:

-

2021

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5.5mx1.8mx1.9m

-

Hollow part volume:

-

200-2000ml

-

Clamping Force (kN):

-

1000

-

Power (kW):

-

49

-

Weight (KG):

-

3900 KG

-

Suitable bottle:

-

Drink Bottle

-

Machine type:

-

Stretch Bottle Blowing

-

Bottle material:

-

Pet Plastic

-

Capacity:

-

9000BPH

-

Advantages:

-

Saving Energy

-

Cavity:

-

6-cavity

-

Fully Auto:

-

Servo motor

-

Processing Type:

-

Stretch Blowing

-

Raw material:

-

PET Tube

-

Machine Weight:

-

5.0 Ton

2,000+ Success Pros

Original Manufactur

e

Money & Cost Saving

|

|

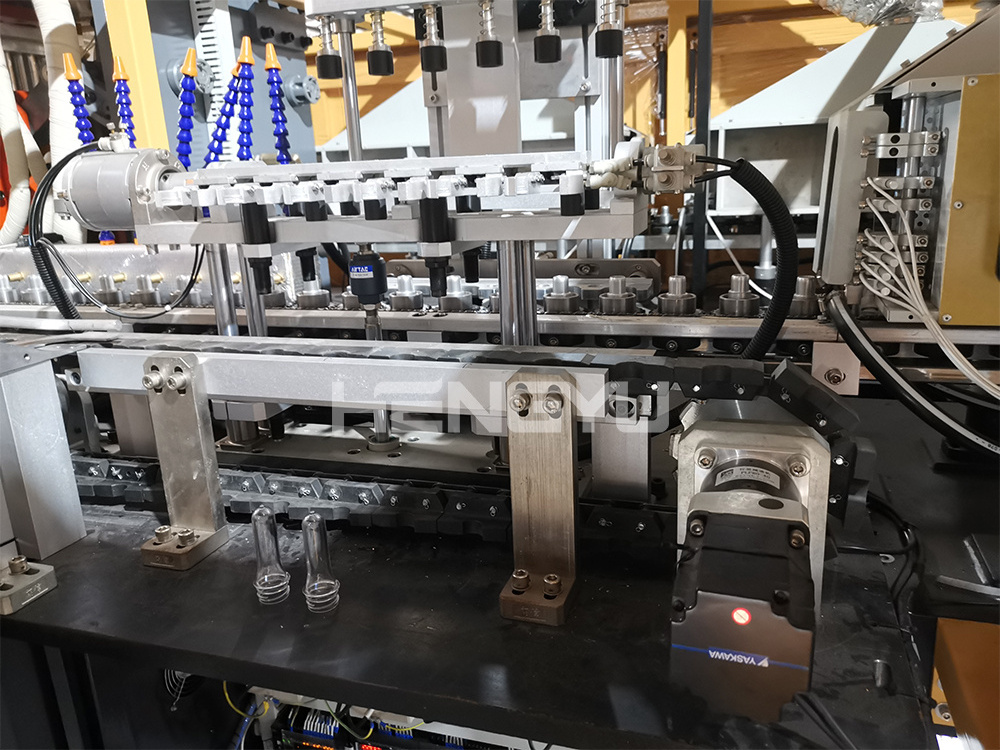

Item

|

HY-6EL

|

|

Main machine

|

Maximum Bottle capacity

|

2000ml

|

|

|

Maximum bottle diameter

|

Φ106mm

|

|

|

Neck diameter

|

Φ18~38mm

|

|

|

Maximum bottle height under neck

|

<330mm

|

|

|

Maximum preform height under neck

|

<155mm

|

|

|

Clamping stroke

|

120mm

|

|

|

Bottom die stroke

|

50mm

|

|

|

Bottle pitch

|

114.3mm

|

|

|

Maximum output rate (bph)

|

8,000(500ml water bottle)

7,200(1500ml water bottle) |

|

|

Number of molds

|

6

|

|

Heating part

|

Number of heating modules

|

5

|

|

|

Number of heating lamps

|

10

|

|

|

Number of preform bases

|

100

|

|

Electric part

|

Voltage

|

220/380V

|

|

|

Frequency

|

50/60Hz

|

|

|

Service power

|

30~40kw/h

|

|

|

Installation power

|

110kw

|

|

Air source

(High pressure air consumption depends on PET bottle volume, altitude) |

Low pressure

|

1Mpa

|

|

|

Low pressure air consumption

|

2m³/min

|

|

|

High pressure

|

3.5Mpa

|

|

|

High pressure air consumption

|

8m³/min

|

|

Cooling water

|

Pressure

|

2~4bar

|

|

Cooling water (≤18℃)

|

Flux

|

9m³/h

|

|

Weight

|

G.W.

|

Around 10 ton

|

|

Dimension

|

Main machine (L×W×H)

|

5800×2600×2600mm

|

|

|

Preform unscrambler(L×W×H)

|

4500×3500×3500mm

|

1)Adopts one-way preform-feeding structure and preform separating by servo motor structure which solve the preform block and abrasion problem.

2)There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder which will warn the operator to add the preforms into the hopper when lacks preform instead of

stopping the machine.

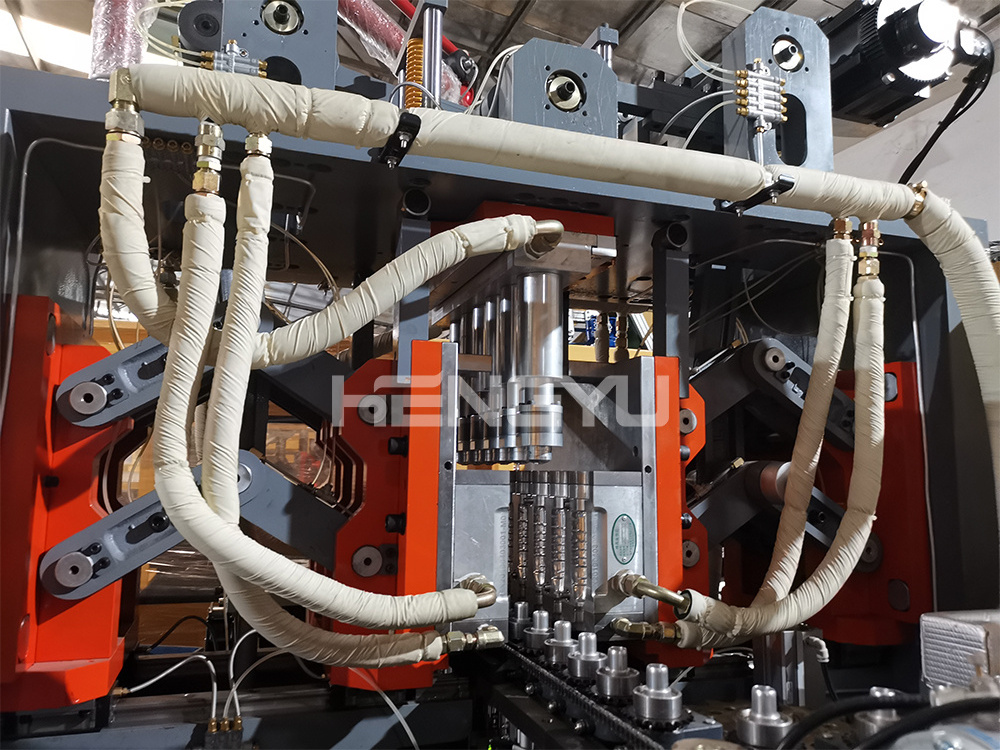

New Heating System

1)Perfect heating system design decrease power consumption.

2)Special oven design helps power saving and easy maintain.

3)Each lamp position and temperature can be adjusted.

4)Cycle air-cooling system keeps the oven temperature constantly.

The Application Of Servo System On Main Transmission

The transmission adopts servomotor for positioning, which can orientate the preform-heating base quickly, accurately and steadily when the machine starts, and running.

Servo Technology Innovation On Clamping System

1)Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

2) Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

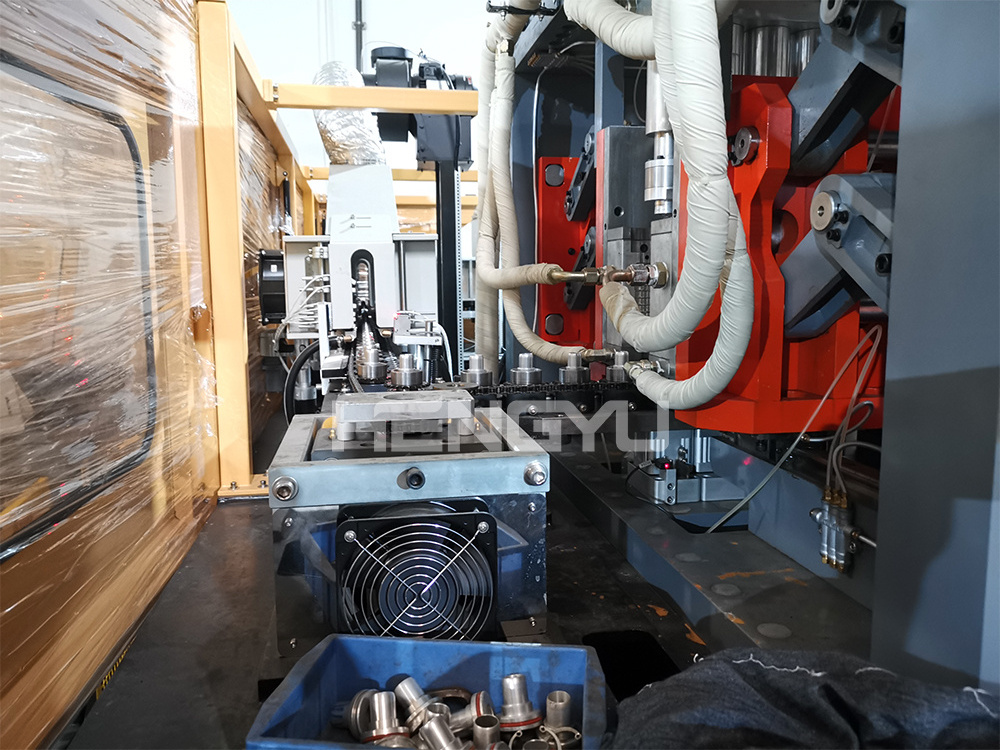

Easy To Change Bottle Shape

Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same bottleneck diameter.

Intelligent Human-Machine Interface

1)Human-machine interface control, easy operates and monitor.

2)Live production information supervise, auto record production data everyday

3)Failure warning and troubleshooting.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter,CNC machine,to ensure the precision ofparts.

<2>The equipment will go through 24 hours' testing and running before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

After equipments reached the workshop of customer, place the equipments according to plane layout we offered. We will arrange seasoned technician for equipments installation, debugging and testing production at the same time to make the equipments reach the rated producing capacity of the line.

Our company offers technology training to customer. The content of training is structure and maintenance of equipments, control and operation of equipments. Training is in the workshop of customer. Seasoned technician will guide and establish training outline.After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They’re made of suitable material, adopts new design. The quality,specification and function all meet the demand of contract.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. After quality guarantee, we offer technology support and after sales service. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.

1/Search Alibaba,Google,Youtube,Facebook and find suppliers and manufacturer,not traders

2/Visit exhibition in different countries

3/Send Hengyu Machinery an request and tell your basic inquiry

4/Hengyu Machinery sales manager will reply you in short time and add instant chatting tool

2.YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

1/If we can full-fill your request and you interested in our products,you may pay a visit to Hengyu Machinery site

2/The meaning of visiting supplier,because seeing is believing,Hengyu Machinery with our own manufacture and developed&research team,we can send you engineers and make sure your after sales service.

3.HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

1/Through Alibaba letter guarantee service,it will ensure the on time delivery and the quality of the equipment you want to buy.

2/By letter of credit,you can lock the delivery time easily.

3/After the factory visit,You can ensure the facticity of our bank account.

4.SEE HENGYU MACHINERY HOW TO ENSURE THE QUALITY!

1/In order to ensure the accuracy of each part,we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

2/Each component before assembly needs strictly control by inspecting personnel.

3/Each assembly is in charged by a master who has working experience for more than 5 years

4/After all the equipment are completed,we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

5.THE AFTER-SALE SERVICE OF HENGYU MACHINERY!

1/After finish the production,we will debug the production line,take photos,videos and send them to customers via mail or instant tools

2/After the commissioning,we will package the equipment by standard export package for shipment.

3/According to the customer's request,we can arrange our engineers to customers' factory to do the installation and training.

4/Engineers,sales managers and after-sales service manager will form a after-sales team,online and off line,to follow the customers' project.