Continuous and uniform feeding is a key step in producing excellent products.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mingxinzhi

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

40000*4000*2800

-

Power (kW):

-

200

-

Weight:

-

2200 KG

-

Raw material:

-

GPPS

-

After-sales Service Provided:

-

Video Technical Support

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

55:1

-

Screw Speed (rpm):

-

1200 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mingxinzhi

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

40000*4000*2800

-

Power (kW):

-

200

-

Weight:

-

2200 KG

-

Raw material:

-

GPPS

-

After-sales Service Provided:

-

Video Technical Support

Product Description

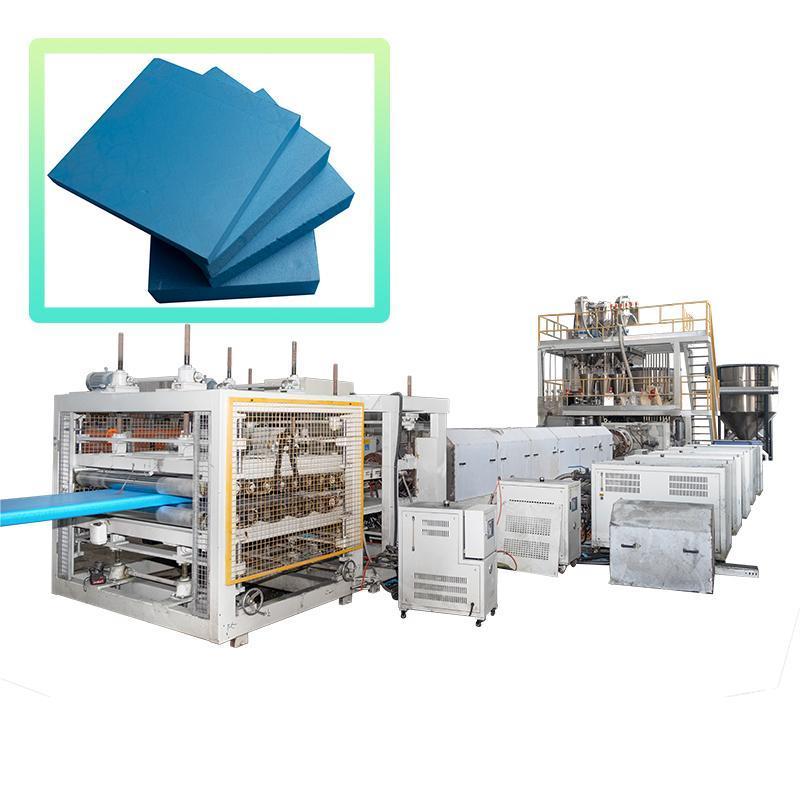

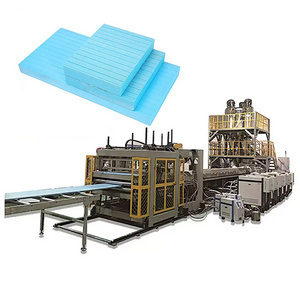

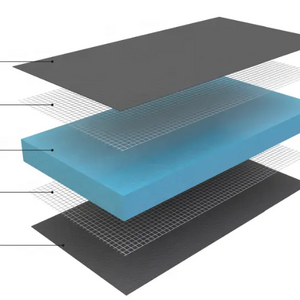

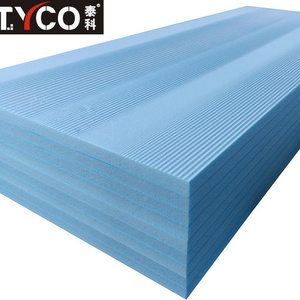

This Product Line Is Used To Produce Xps Physical Foamed Board, Also Named As Thermal Insulation Extrusion Polystyrene Foam, With Perfect Closed-Pore Alveolate Structures. Its Density, Water Absorption, Coefficient Of Heat Conducting And The Coefficient Of Steam Pervasion Are All Lower Than Other Thermal Insulation Materials. Xps Physical Foamed Board Performs Very Great On Strong Intensity, Light Material, Airtight, Anticorrosion, Aging Resistance, As Well As The Price Is Competitive. That’S Why We Design This Machine Line, To Help Architects Design And Build Better Buildings.

|

Model

|

XS-MXZ-120-300-1300

|

XS-MXZ-95-250-1300

|

XS-MXZ-75-160-1300

|

|||

|

Screw diameter (mm)

|

120-300mm

|

95-250mm

|

75-160mm

|

|||

|

Width of XPS foam Board

|

450-1250mm

|

|

|

|||

|

Thickness of XPS foam Board

|

20-150mm

|

|

|

|||

|

Transformer Required

|

300-1200KVA

|

|

|

|||

|

Blowing Agent

|

CO2/Enathol/DME/HCFC/HFO/PROPANE

|

|

|

|||

|

Throughput (kg/h)

|

950~1400

|

750~1000

|

350~400

|

|||

|

|

|

|

|

|||

|

Model

|

XS-MXZ-110-300-1300

|

XS-MXZ-135-400-1300

|

XS-MXZ-135-500-1300

|

|||

|

Screw diameter (mm)

|

110-300mm

|

135-400mm

|

135-500mm

|

|||

|

Width of XPS foam Board

|

450-1250mm

|

|

|

|||

|

Thickness of XPS foam Board

|

20-150mm

|

|

|

|||

|

Transformer Required

|

300-1200KVA

|

|

|

|||

|

Blowing Agent

|

CO2/Enathol/DME/HCFC/HFO/PROPANE

|

|

|

|||

|

Throughput (kg/h)

|

800~1200

|

1500~2000

|

2000~3000

|

|||

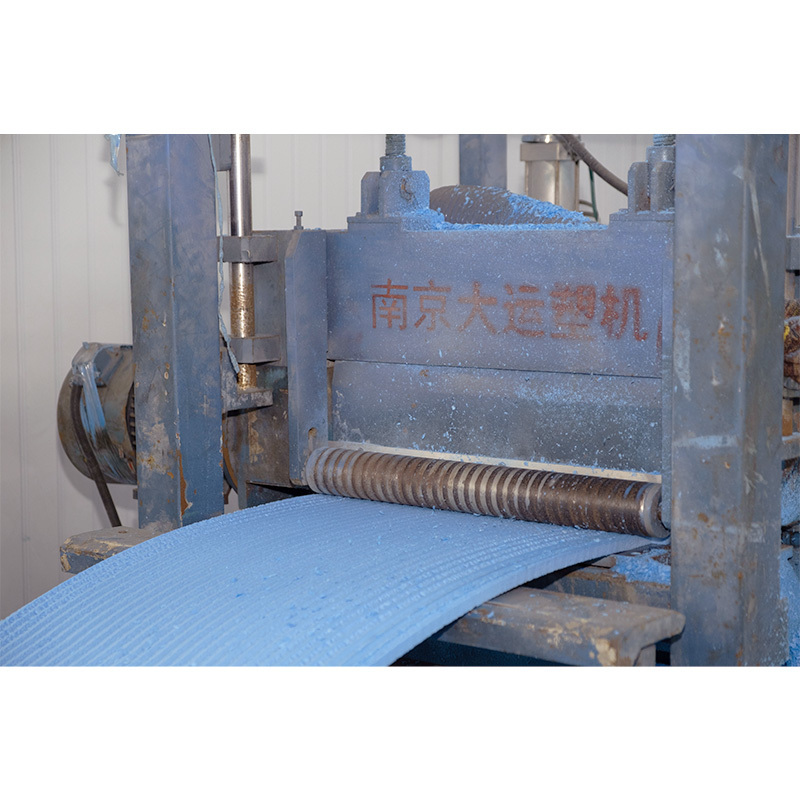

Fully Automatic Raw Material Handling System

In comparison to typical domestically produced compounding twin screw extruders, our extruders are very different, as we adopt

TDS-D series high torque, which brings the specific torque of our extruders up to 10.3 Nm/cm3.

Blowing Agent System

We have designed a CO2 system which controls all the key parameters, to ensure precise metering. Our multiple blowing agent

injection system allows you to shift the product portfolio easily, quickly adjusting to suit different market conditions. This

also assures constant quality and cost control, therefore maximizing your profit margins.

We provide complete downstream systems, including calibrator, haul-off, edge trimming, cut-off, stacker, and auto-packaging

system.

Product packaging

• For the loose cargo we will packing by wooden box.

• For the full container loading we are packing the machine by film and some on pallet accordingly.

• We can also ship the goods by air or by sea as buyer request.

• We will send pictures of cargo loading to our client to check and keep recording.

• We can send cargo to client's warehouse to loading.

• For the full container loading we are packing the machine by film and some on pallet accordingly.

• We can also ship the goods by air or by sea as buyer request.

• We will send pictures of cargo loading to our client to check and keep recording.

• We can send cargo to client's warehouse to loading.

Customer Photos

Hot Searches