- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5~455 KW, 5.5~15 kW

-

Weight:

-

800~150000 KG, 800~1500 KG

-

Dimension(L*W*H):

-

50000*10000*15000 mm

-

Product Name:

-

Paddy Rice Husker

-

Rated Capacity:

-

1~10 t/h

-

Air Volume:

-

3400~7400 m3/h

-

Rubber Roll 1 (D*L):

-

254*254 mm

-

Rubber Roll 2 (D*L):

-

225*356 mm

-

Rubber Roll 3 (D*L):

-

254*508 mm

-

Structure:

-

Mechanical/Pneumatic

-

Use:

-

Paddy Rice Husks Removal Machine

-

Certification:

-

CE, ISO, SONCAP, CO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

COFCO

-

Voltage:

-

110~600 V

-

Power:

-

7.5~455 KW, 5.5~15 kW

-

Weight:

-

800~150000 KG, 800~1500 KG

-

Dimension(L*W*H):

-

50000*10000*15000 mm

-

Product Name:

-

Paddy Rice Husker

-

Rated Capacity:

-

1~10 t/h

-

Air Volume:

-

3400~7400 m3/h

-

Rubber Roll 1 (D*L):

-

254*254 mm

-

Rubber Roll 2 (D*L):

-

225*356 mm

-

Rubber Roll 3 (D*L):

-

254*508 mm

-

Structure:

-

Mechanical/Pneumatic

-

Use:

-

Paddy Rice Husks Removal Machine

-

Certification:

-

CE, ISO, SONCAP, CO

KAIFENG HYDE MACHINERY CO., LTD.

COFCO - MAOSHENG GROUP

u 50 YEARS MANUFACTURING EXPERIENCE SINCE 1976.

u CHINA TOP 10 GRAIN PROCESSING MACHINERY MANUFACTURING COMPANY.

u MEMBER OF 13 CHINA NATIONAL STANDARDS DRAFTER IN GRAIN PROCESSING INDUSTRY.

u 75 PATENTED TECHNOLOGIES AND PRODUCTS.

u 600,000 SQUARE METER PRODUCTION AREA.

u OVER 100 EXPERIENCED ENGINEERS, RESEARCH STAFF AND TECHNICIANS.

u STATE-OF-THE-ART FACILITIES. ADVANCED IMPORTED CNC MACHINES FOR FUNCTION PARTS.

u FULL RANGE OF SERVICE, FROM SINGLE MACHINE TO TURNKEY SYSTEMS IN GRAIN AND FLOUR INDUSTRY.

u MACHINERY AND EQUIPMENT QUALITY TESTED BY DOMESTIC AND GLOBAL MARKET, RICH INSTALLATION AND TROUBLE-SHOOTING EXPERIENCE.

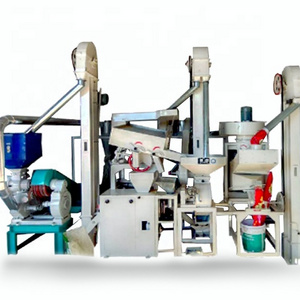

MLGQ Paddy Rice Husker:

Structure Drawing s:

MLGQ Paddy Husker With Aspirator Is A Newly Developed And Ideal Upgrade Product For Modern Rice Milling Plant.

It Is Widely Used In Middle And Large Rice Milling Plant Due To Its Large Capacity Which Can Satisfy The Requirement Of Centralization Production.

(1). Automatic Control Equipment Action Sequence Can Realize Automatic Tightening Of Rollers, Automatic Loosening Of Rollers Without Material, Convenient Operation And Adjustment.

(2). The Pressure Between The Rollers Is Linearly Controlled By Air Pressure, The Output Is Digitally Adjusted And Displayed, And The Pressure And Product Adjustments Are Simple And Intuitive.

(3). Adopting The Vibrating Forced Feeding Technology Of The Color Sorter, The Long Slab Accelerates The Rectification, The Output Is High, The Rough Shredded Paper, And The Economic Benefit Is Significant.

(4). The First Double Support Structure, Stable Transmission And Stable Mechanical Performance.

(5). The Chaff Separation Method Is A Vertical Suction Duct Structure.

Technical Specification :

Notes:

Stable Performance High Rate Of Husking And Less Broken Percentage And Good Separating Effect For Brown Rice.

The Paddy Hull, Husker Head Adopted Automatic Control, Husking Rate Is About 90%.

It Insure Stable Husking Rate During Processing.

Optimum Performance, Durability Rubber Roll Huskers.

High Level Of Automation, The Tensity Of Two Rubber Rollers Are Controlled By Pneumatic Cylinder.

It Connected With Level Detector And Release The Roller When There Is No Paddy In Hopper, And Engage The Roller After There Is Enough Paddy In Feeding Hopper In Time.

The Pressure Between Rubber Rolls Can Be Easily Adjusted By The Cylinder.

Equipt Perfect Motor Overloading Automatic Protection Function.

Easy To Be Operated, The Rubber Roller Can Be Changed By One Operator Easily.

Inspection Easy With Visible Glass Window, Friendly Environment With Full Seal.

Paddy Rice Milling Processing Plant:

Whole Plant Drawings:

- Turkey Projects From 10 Tones Per Day To 120 Tones Per Day To 1500 Tones Per Day .

- Building Structure And Steel Structure. :

40'HQ Or 20'GP CONTAINERS Or Wooden Box Packaged: