- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Raintech

-

Voltage:

-

220V/380V

-

Weight (KG):

-

1500

-

Product name:

-

Shearing Bending Punching Busbar Machine for Transfer Industry

-

Application:

-

Transformer Industry

-

Keywords:

-

Busbar Machine Punching Molds

-

Processing material:

-

Copper Aluminum Bus Bar

-

Machine Type:

-

CNC Control

-

Package:

-

Wooden Case

-

Bending type:

-

CNC Control Busbar Machine

-

Color:

-

Customer's Requirement

Quick Details

-

Max. Thickness (mm):

-

15 mm

-

Max. Width (mm):

-

160 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Raintech

-

Voltage:

-

220V/380V

-

Weight (KG):

-

1500

-

Product name:

-

Shearing Bending Punching Busbar Machine for Transfer Industry

-

Application:

-

Transformer Industry

-

Keywords:

-

Busbar Machine Punching Molds

-

Processing material:

-

Copper Aluminum Bus Bar

-

Machine Type:

-

CNC Control

-

Package:

-

Wooden Case

-

Bending type:

-

CNC Control Busbar Machine

-

Color:

-

Customer's Requirement

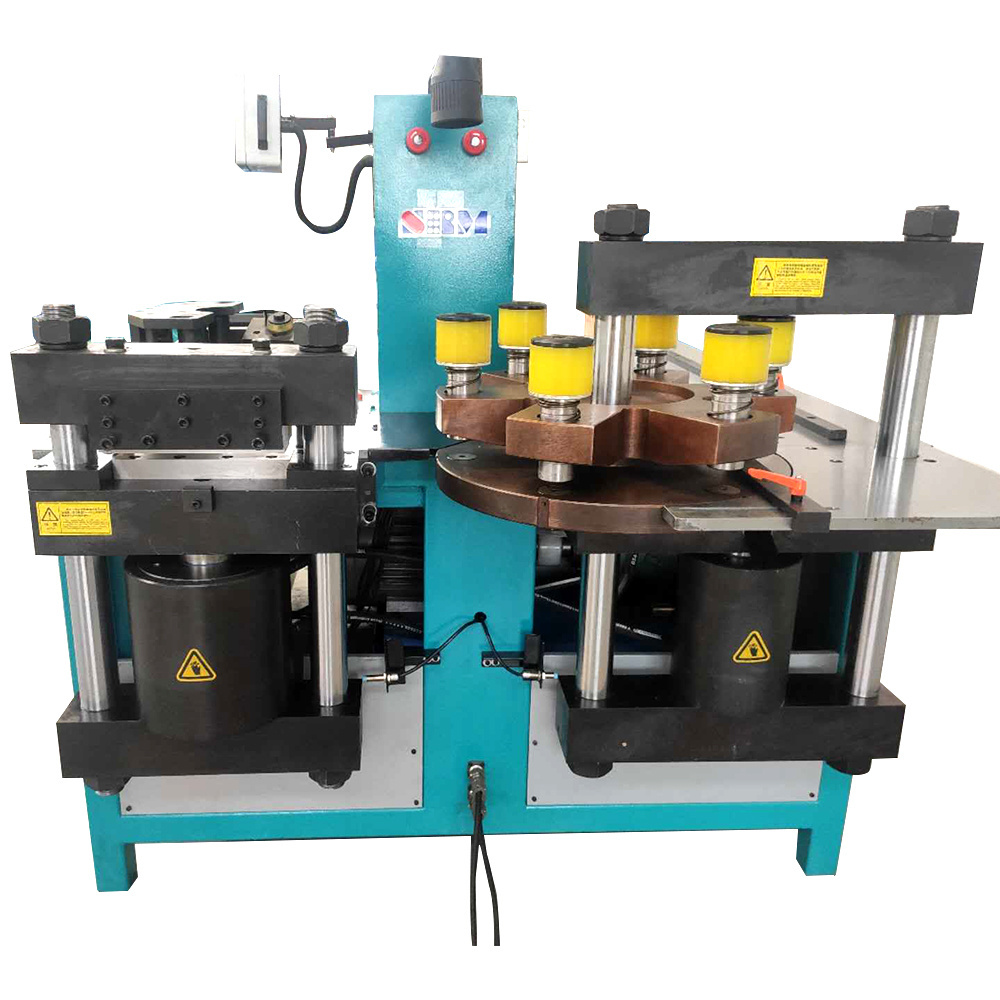

Raintech Multifunction Busbar Processing Machine with High Speed and Quality

Product Description

ZTMX series busbar punching bening cutting embossing machine for

copper

Product Parameters

TECHNICAL PARAMETER

|

Model

|

ZTMX-301

|

ZTMX-303

|

ZTMX-501

|

ZTMX-503

|

|

|

Max.punching force

|

350

|

350

|

500

|

500

|

|

|

Max.processing range

|

Φ4.3-φ35

|

Φ4.3-φ35

|

Φ4.3-φ36

|

Φ4.3-φ36

|

|

|

Max.punching thickness

|

12

|

12

|

18

|

18

|

|

|

Max. shearing thickness

|

12

|

12

|

18

|

18

|

|

|

Max.shearing width

|

160

|

160

|

260

|

260

|

|

|

Max. bending force

|

350

|

350

|

550

|

550

|

|

|

Max. bending width

|

160

|

160

|

260

|

260

|

|

|

Max.bending width into flat bend

|

16

|

16

|

20

|

20

|

|

|

Max.processing size of vertical bend

|

125*12

|

125*12

|

125*12

|

125*12

|

|

|

Main motor power

|

4

|

4(3 pcs)

|

5.5

|

5.5(3 pcs)

|

|

|

Machine weight approx.

|

1.2

|

1.4

|

1.8

|

2.2

|

|

|

Dimension

|

1800*1400*1300

|

1800*1400*1400

|

2000*1500*1400

|

2000*1500*1500

|

|

|

1 level worktable size

|

1770*1240

|

1770*1240

|

1840*1450

|

1840*1450

|

|

|

2 level worktable size

|

/

|

890*500

|

/

|

1000*500

|

|

|

Shearing,punching and bending work simultaneously

|

/

|

yes

|

/

|

yes

|

|

Product Details

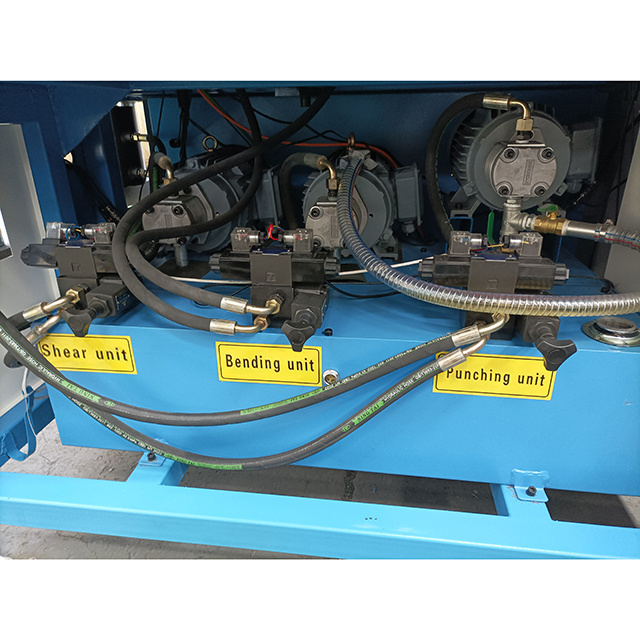

1. The shearing unit adopts the double column double knife shearing structure, the upper and lower knives are installed vertically and parallel to ensure a smooth cut, and no burr, no waste generation.

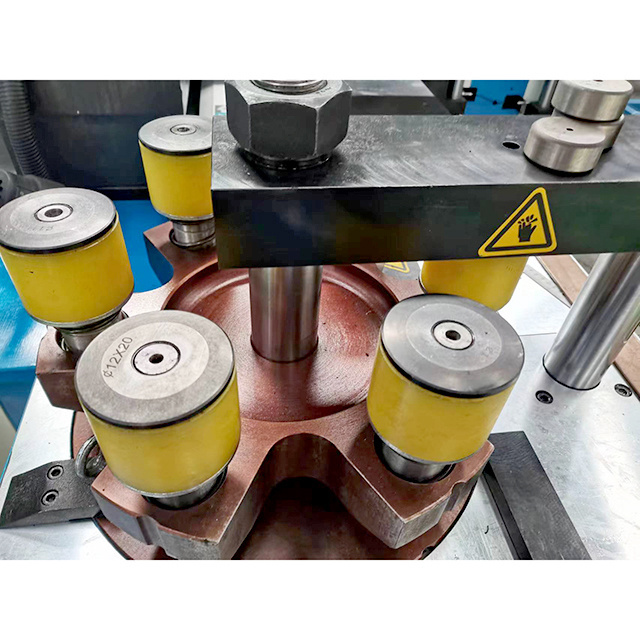

2.The punching unit adopts six die positions of integral turntable, (the turntable is an integrated processing parts, mold mounting holes for CNC machining center, high precision, mold and turntable with a clearance of 0.00-0.05mm), improve the concentricity of the mold, prolong the service life , in addition to the use of frequent replacement , improve efficiency.

3.The bending unit adopts closed bending, and the output point and the stress point are connected by a 50mm thick cross beam, which greatly enhances the mechanical strength compared with open bending.

4.The three working stations of the machine can work simultaneously, which greatly improves the working efficiency.

The three processing units of punching, shearing and bending are all controlled by a double foot pedal,In the case of automatic control mode, even if the upper and lower limits of each station are disconnected, it will never affect the user's production use, thus reducing the failure rate of the equipment and eliminating the safety hazards such as the rupture of the oil pipe of the pump that occurred in the past when the limit switch of the equipment failed. In the case of manual control mode, the operation of each station is simple and convenient, thus improving production efficiency.

Sample Display

WORKPIECE SHOW

Recommend Products

Packing&Shiping

We have cooperated with experienced shipping forwarders for many years, they arrange the shipment. No matter by express, by air or by sea, we will track the course of the goods all the way, to make sure goods arrive at you on time and in good condition.

We support online maintenance and offline engineer guidance at the factory.

Company Introducation

SHANDONG RAINTECH SANS TECHNOLOGY co., LTD

is a professional group for CNC machines with more than 13 years experience. Plant now covers an area of more than 12000 square meter, annual capacity is around 200 units. Raintech have an experienced expert with young active technical team, which can provide the professional with improved design solutions for our customers, assure that can satisfy various customer's special requirements by cost- effective way.

ENTERPRISE CERTIFICATE

International exhibitions

Customer visits

FAQ

♥1.How to operate the machine ?

We will deliver English manual and video with the machine to you. lf you still need our help,please contact us.

♥2.If some problems happen to this machine during warranty period, what should I do?

We will supply free charge of spare parts and regularly maintenance service during machine warranty period if machine have some problems. So any doubts, just let us know, we will give you solutions.

♥3.Does the machine can be customized according to my requirements ?

Yes, we have a strong technical team and have rich experience.

♥4. What about the package and shipment ?

The machine will be packaged by multilayer plastic wrap for anti-humidity on the sea. The strong steel wire roops will be used for fix the machines in container to avoid any damage in transportation.

♥2.If some problems happen to this machine during warranty period, what should I do?

We will supply free charge of spare parts and regularly maintenance service during machine warranty period if machine have some problems. So any doubts, just let us know, we will give you solutions.

♥3.Does the machine can be customized according to my requirements ?

Yes, we have a strong technical team and have rich experience.

♥4. What about the package and shipment ?

The machine will be packaged by multilayer plastic wrap for anti-humidity on the sea. The strong steel wire roops will be used for fix the machines in container to avoid any damage in transportation.

Hot Searches