The platen structure is designed with European style and fully optimized parameters and force distribution. High-rigidity materials and manufacturing processes for base frame ensure the machine is strong, stable and reliable.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Product name:

-

Plastic Injection Moulding Machine

-

Function:

-

High Efficiency

-

Usage:

-

Injection Molding Machine Making Plastic Injection

-

Used for:

-

Plasic Products

-

Structure:

-

Horizontal Injection Molding Machine

-

Advantages:

-

High Speed High Efficiency

-

After-sales Service:

-

Over-sea Service Provided

-

Keyword:

-

Used Injection Molding Machine

-

Motor:

-

Servo Energy Saving

-

BRAND:

-

CHEN HSONG

Quick Details

-

Injection Rate (g/s):

-

108 g/s

-

Injection Weight (g):

-

139 g

-

Weight (KG):

-

3460 kg

-

Place of Origin:

-

Guangdong, China

-

Product name:

-

Plastic Injection Moulding Machine

-

Function:

-

High Efficiency

-

Usage:

-

Injection Molding Machine Making Plastic Injection

-

Used for:

-

Plasic Products

-

Structure:

-

Horizontal Injection Molding Machine

-

Advantages:

-

High Speed High Efficiency

-

After-sales Service:

-

Over-sea Service Provided

-

Keyword:

-

Used Injection Molding Machine

-

Motor:

-

Servo Energy Saving

-

BRAND:

-

CHEN HSONG

Specifications

|

Brand Name

|

Chenhsong

|

|

Model

|

JM98-Ai

|

|

Year

|

2018-2019

|

|

Style

|

Horizontal

|

|

Machine Type

|

Hydraulic

|

|

Key Selling Points

|

Energy saving

|

|

Plastic material

|

PP, PC, ABS, PET, PVC, HDPE, ABS/PP and so on

|

|

Applicable Industries

|

Manufacturing Plant

|

|

Screw diameter

|

36 mm

|

|

Theoretical Shot Volume

|

153cm³

|

|

Injection Weight

|

139g

|

|

Distance between Tie Bars

|

360*360

|

|

Clamping Force

|

980 kN

|

|

Pump Motor Power

|

11 kW

|

|

Weight

|

3.46T

|

|

Size

|

4.20*1.18*1.84

|

|

Warranty

|

1 Year

|

|

After-sales Service Provided

|

Video technical support, Free spare parts, Online support

|

|

Place of Origin

|

China

|

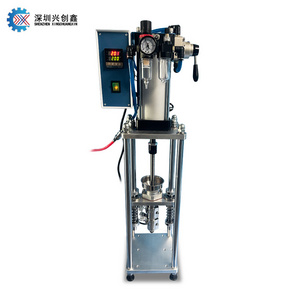

Details Images

Product Advantage

Injection molding machine, also known as injection molding machine or injection machine. It is the main forming equipment for plastic products which are made of thermoplastic or thermosetting plastic by using plastic molding mould. Divided into vertical,horizontal, all electric. The plastic injection molding function heats the plastic, and exerts high pressure on the molten plastic, so that the injection molding cavity is filled with the mold cavity.

Machines are classified primarily by the type of driving systems they use: hydraulic, mechanical, electric, or hybrid.Injection molding machine is usually composed of injection system, mold clamping system, hydraulic transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system, and so on.

Control System

Programmable Logic Controller, an automated control system that controls the process requirements (pressure, temperature, speed, time) and various program actions of the injection machine by entering various commands.

Expandable with multiple modules including AO, AI, DO, DI, and TM to meet more requirements; Real-time monitoring of signals from machine equipped sensors to coordinate corresponding movements for higher operating safety.

Integrated linear guide rail support Medium size machine adopts integrated linear guide rail, horizontal double-carriage design

and double-cylinder injection to ensure injection is reliable & stable.

Integrated linear guide rail support reduces the friction between injection unit and linear guide rail or tie bar and enhances

production repeatability.

Hydraulic System

Low energy consumption, strong power and fast response.

Overall hydraulic circuit optimization reduces flow loss.

The resistance to moving parts, including the clamping unit and injection unit is further reduced, raising the response speed and reducing frictional loss.

Recommend Products

Applications

Why Choose Us

More than 20 years of industry experience

Our company has more than 20 years of industry experience, and many experienced engineers can find injection molding machines suitable for your needs in a short time.

Large inventory

We have injection molding machines of various tonnage and their supporting products. We have built and cooperated with more than 10 warehouses. The number of injection molding machines in the warehouse is large, and we can find the machines that meet your needs.

Highly professional

We operate injection molding machines of various mainstream brands.

We have worked hard for many years to find machines with low price and good quality. We believe that we can succeed only if we are professional.

Custom service

We have a number of professional engineers, which could customize the machine you need according to your needs, and save you money to produce the products you want.

Product Packing

FAQ

1.Q: Are you a manufacture or a trading company ?

A: We are a manufacturer in Shenzhen city, Guangdong Province, China.

2. Q: Why should i choose your company and your products ?

2. Q: Why should i choose your company and your products ?

A: We have been in this field for more than 20 years, and our quality is good. Due to our good quality ,some of the famous companies are also using our products ,such as ,Apple ,Foxconn, BYD, etc.

3. Q:Do you accept customization service ?

A:Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4. Q:What is the order process ?

A: Inquiry - quotation - communication - order confirming - deposit payment - production - testing and debugging - balance

payment -packing - delivery - customer receiving - after sale service.

5.Q: I want make a plastic product, but I don't know how to choose a suitable machine model, what should I do ?

3. Q:Do you accept customization service ?

A:Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4. Q:What is the order process ?

A: Inquiry - quotation - communication - order confirming - deposit payment - production - testing and debugging - balance

payment -packing - delivery - customer receiving - after sale service.

5.Q: I want make a plastic product, but I don't know how to choose a suitable machine model, what should I do ?

A: Please feel free to tell us about the product detail information, such as size weight, how many output you prefer per hour. We will help make good proposal with nice price for you.

Hot Searches