- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1200 KG

-

Power (kW):

-

7KW

-

Name:

-

wood brush sander

-

Application:

-

Wood

-

Motor:

-

Stepper Motor

-

Type:

-

Full-automatic

-

Model:

-

630/1000/1300

-

Color:

-

Customers Requirement

-

Key words:

-

polishing machine

-

Key word:

-

machine

-

Feature:

-

Economic

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

grandio

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

1200 KG

-

Power (kW):

-

7KW

-

Name:

-

wood brush sander

-

Application:

-

Wood

-

Motor:

-

Stepper Motor

-

Type:

-

Full-automatic

-

Model:

-

630/1000/1300

-

Color:

-

Customers Requirement

-

Key words:

-

polishing machine

-

Key word:

-

machine

-

Feature:

-

Economic

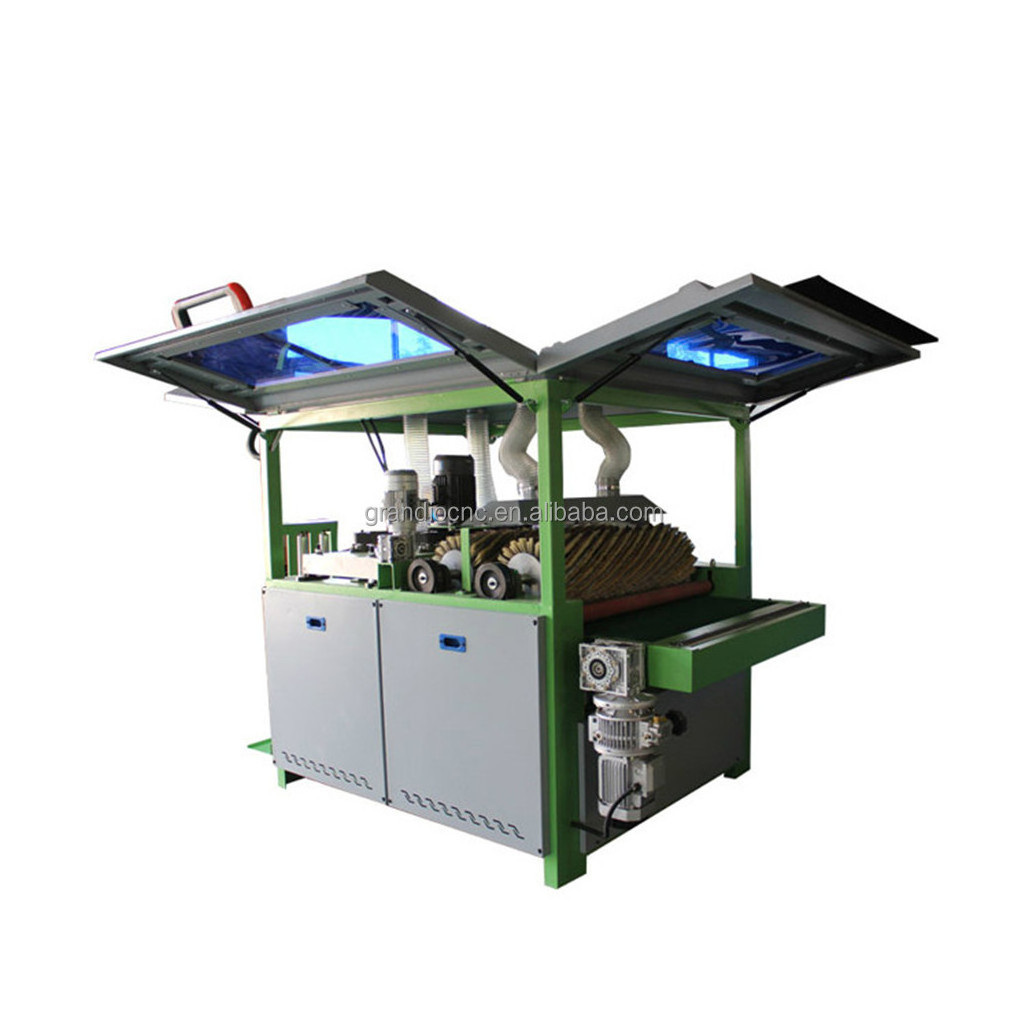

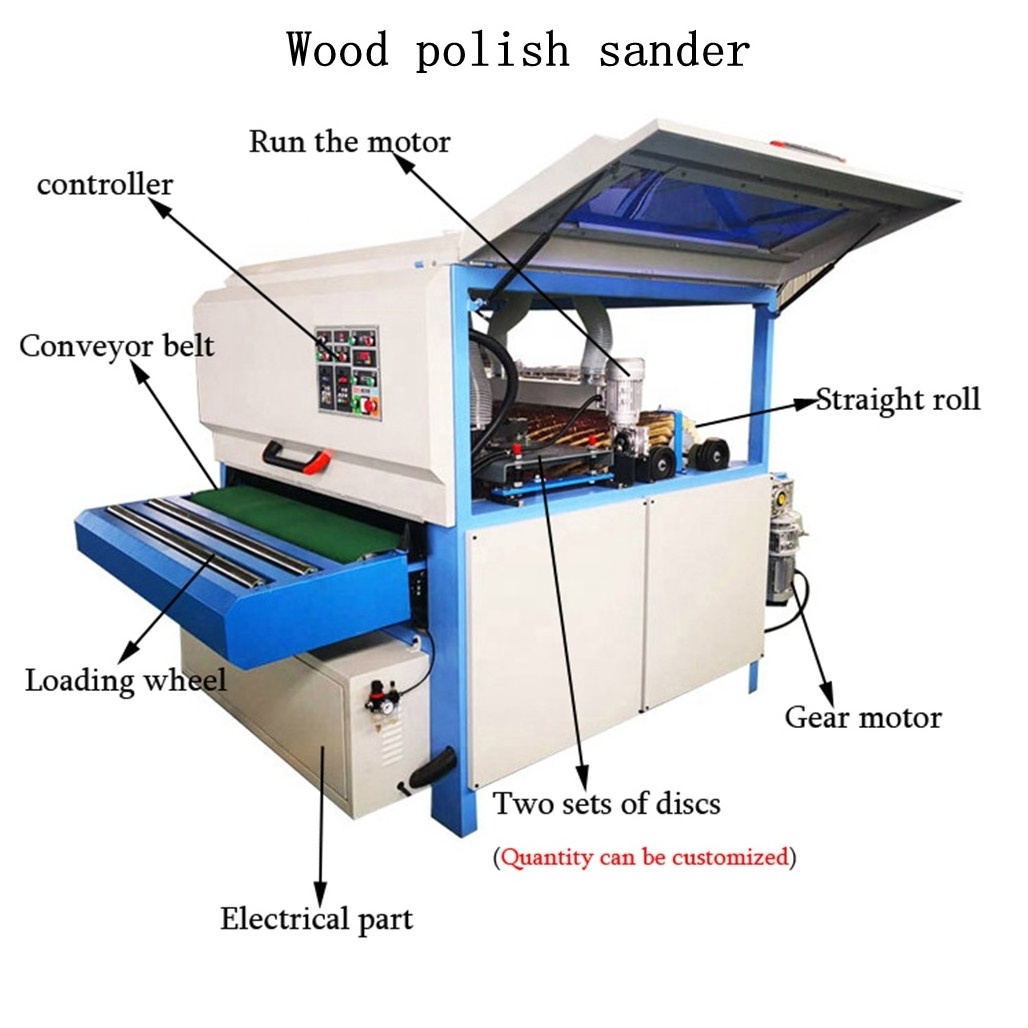

Product Description

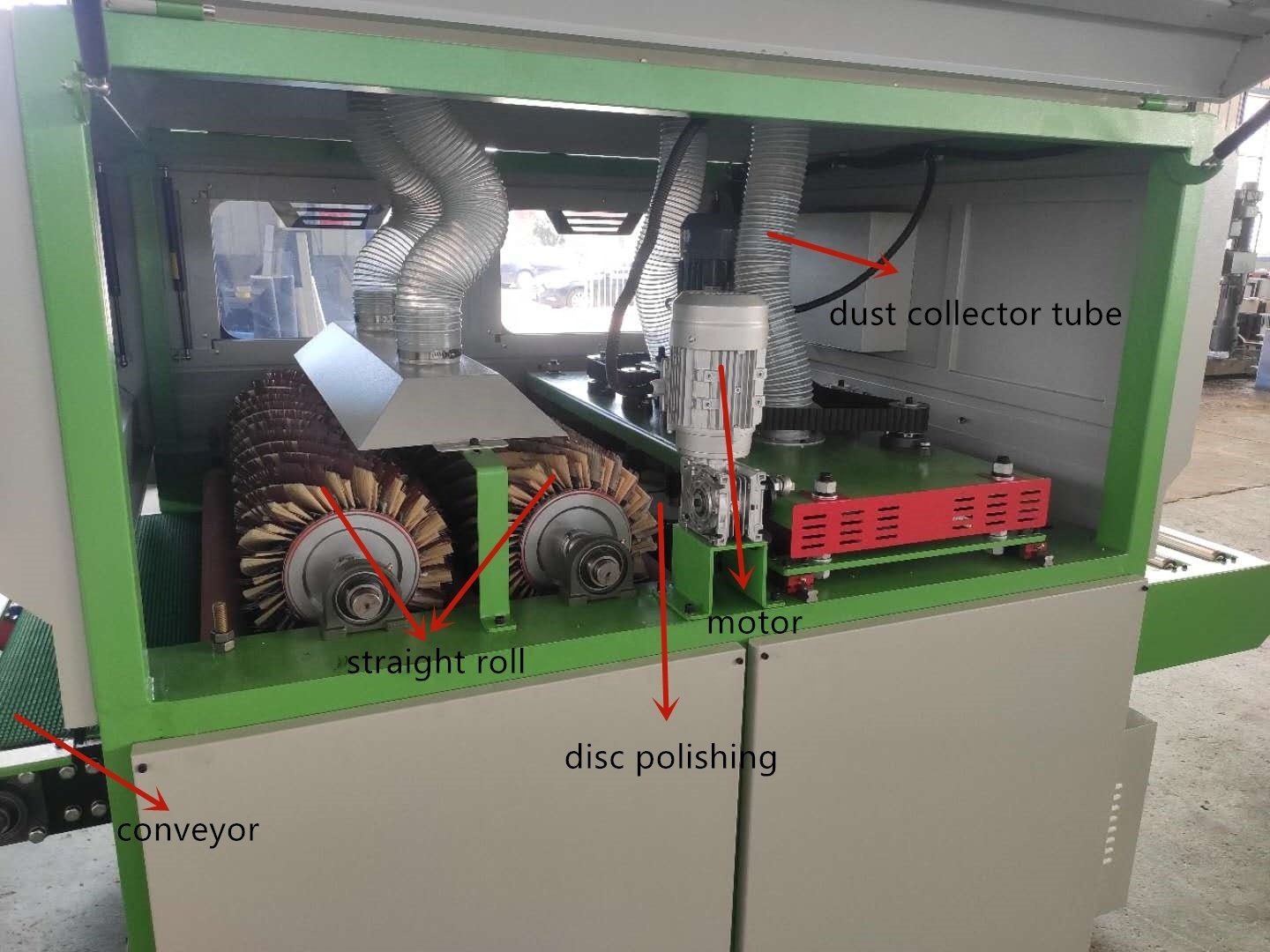

Mechanical Features

Drum sanding wood with wrapped emery cloth (paper), available in single-roll and multi-roll types. In addition to rotating during processing, the roller can also move back and forth in the axial direction to reduce the surface roughness of the workpiece. Single-roll sanding machines mostly use manual feeding, and multi-roll workpieces are fed by pressure rollers and upper and lower feed rollers or conveyor belts. This type of sanding machine is suitable for sanding the surface of sheet, square, plywood, plywood, particleboard and fiberboard.

▲ Belt woodworking sander

▲ Belt woodworking sander

Tension the endless endless abrasive belt on 2 or 3 pulleys, drive the abrasive belt to move continuously, and one tension pulley also makes a small amount of warping to make the abrasive belt move laterally. The sanding machine for flat surface processing has a fixed or movable table; the sanding machine for curved surface processing uses the flexibility of the abrasive belt to process the workpiece under the pressure of the template. The wide-band woodworking sander has the advantages of high efficiency, guaranteed processing accuracy, and easy replacement of the abrasive belt. It is suitable for sanding of large wood-based panels, furniture panels, decorative panels, or panels before and after painting.

▲

Disc woodworking sander

Use the sandpaper (cloth) attached to the end surface of the rotating disc to sand the workpiece. There

are vertical and horizontal, single disc and double disc. The workpiece is fed manually or motorized, used for flat sanding,

suitable for manufacturing industries such as carriages, furniture and wooden molds.

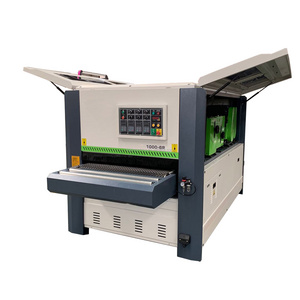

Specification

|

Model

|

GD-630

|

GD-1000

|

GD-1300

|

|

|||

|

Working width

|

30-630mm

|

30-1000mm

|

30-1300mm

|

|

|||

|

Size of Abrasive Belt

|

650*1900mm

|

1020*2000mm

|

1320*2200mm

|

|

|||

|

Working thickness

|

2-100mm

|

|

|

|

|||

|

Feeding speed

|

5-25m/min

|

|

|

|

|||

|

Inverter

|

5.5KW+1.5kw

|

|

|

|

|||

|

Reducer motor

|

1.5kw

|

|

|

|

|||

|

Total power

|

11kw

|

|

|

|

|||

|

Air pressure

|

>0.55Mpa

|

|

|

|

|||

|

net weight

|

1600kg

|

|

|

|

|||

|

Voltage

|

220V/380v

|

|

|

|

|||

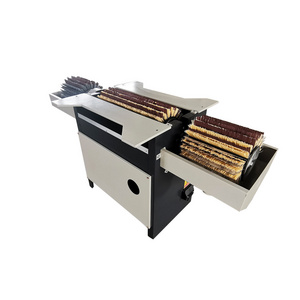

Polishing Roller

Equipped with different materials according to actual needs to make polishing more complete

One-button operating system, green on, red off is convenient and simple, not easy to make mistakes

Adopt national standard pure copper motor, reject aluminum core, copper clad aluminum.

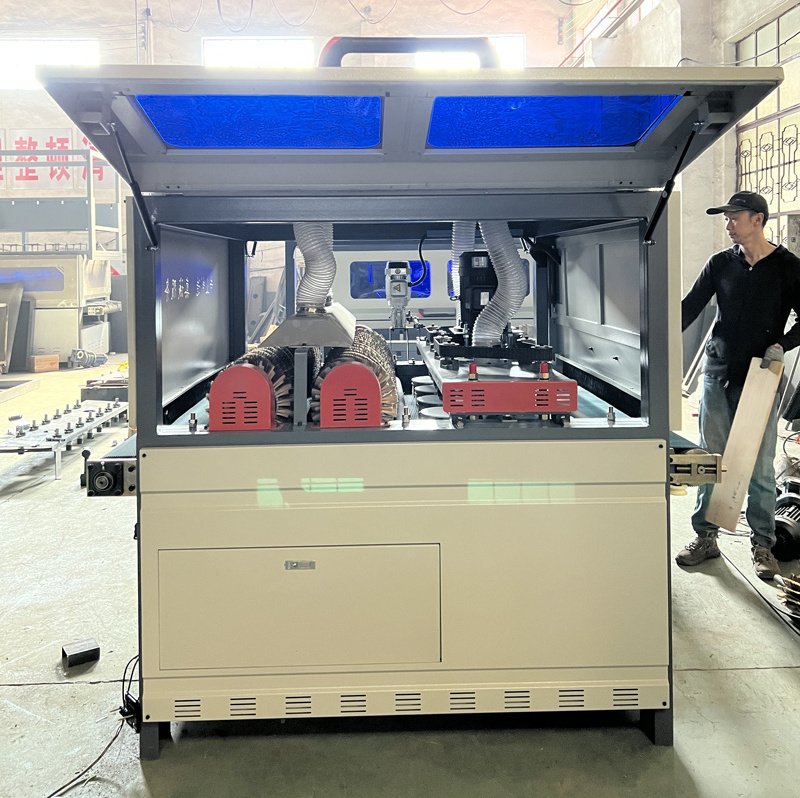

Customer Photos

Our Advantages

Packaging and Shipping

The wooden box is sealed and packaged for safe transportation and effectively prevent bumps.

Because the machinery is relatively heavy, shipping is generally chosen.

Shipping and payment methods can be negotiated with customer service

.

Exhibition

Hot Searches